UX-P115U

3 – 2

3.5. Documents requiring use of the copy

1) Documents smaller than 148mm (W) x 140mm (L).

2) Documents thinner than the thickness of 0.06mm.

3) Documents containing creases, folds, or curls, especially those

whose surface is curled (maximum allowable curl is 5mm).

4) Documents containing tears.

5) Carbon-backed documents. (Insert a white sheet of paper between

the carbon back and the document carrier to avoid transfer of car-

bon to the carrier.)

6) Documents containing an easily separable writing material (e.g.,

those written with a lead pencil).

7) Transparent documents.

8) Folded or glued documents.

4. Document release

4.1. General

To correct a jammed document or to clean the document running sur-

face, pull the insertion side of document center of the operation panel.

To open the upper document guide, the operation panel must be

opened first.

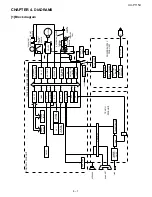

5. Recording block

5.1. Driving

In the drive mechanism, the rotating force of the pulse motor for both

transmission and reception is transmitted to the paper supply roller,

the recording paper feed roller and imaging film drive gear through the

pulse motor axle gear, reduction gear and planetary gear.

5.2. Recording

This equipment employs the thermal transcription system which uses

the thermal head imaging film.

5.2.1 Thermal head

The thermal head is composed of 2,016 heating elements in traverse

line, and the resolution power is 8 dots/mm. The maximum speed is 10

ms/line.

5.2.2 Structure of recording mechanism

Recording is achieved by applying a suitable pressure to the thermal

head through the imaging film of the recording paper feed roller and

the recording paper.

The main scanning is electronically performed, and the sub-scanning

is mechanically performed (by sending the recording paper with the

recording paper feed roller).

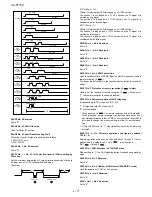

5.2.3 Recording paper transfer sequence

1) The recording paper stored in the paper tray ass’y is fed with the

PU roller, and is stopped when the P-IN sensor is turned on by

sensing its lead edge.

2) Hereafter, the imaging film and recording paper are transferred with

the recording paper feed roller, and thermal transcription is per-

formed on the recording paper.

3) After thermal transcription, the imaging film is taken up by the roller

on the take-up side, and the recording paper is discharged by the

back roller.

Troubleshooting the density unevenness mainly results from the

longitudinal misalignment of the thermal head to the heater line.

Otherwise, the head is in uneven contact with the recording paper

feed roller, or the imaging film is wrinkled.

The following items are described as the simplified checking

method.

a) Are the power and signal cables of the thermal head suitably

treated?

b) Does the same symptom appear even if the thermal head pres-

sure spring is replaced?

c) Is the feed roller of the recording paper concentric? (Density is

uneven at intervals.)

d) Does the same symptom appear even if the thermal head is

replaced?

e) Is the imaging film stained or wrinkled?

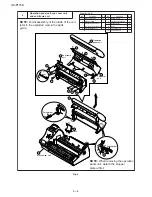

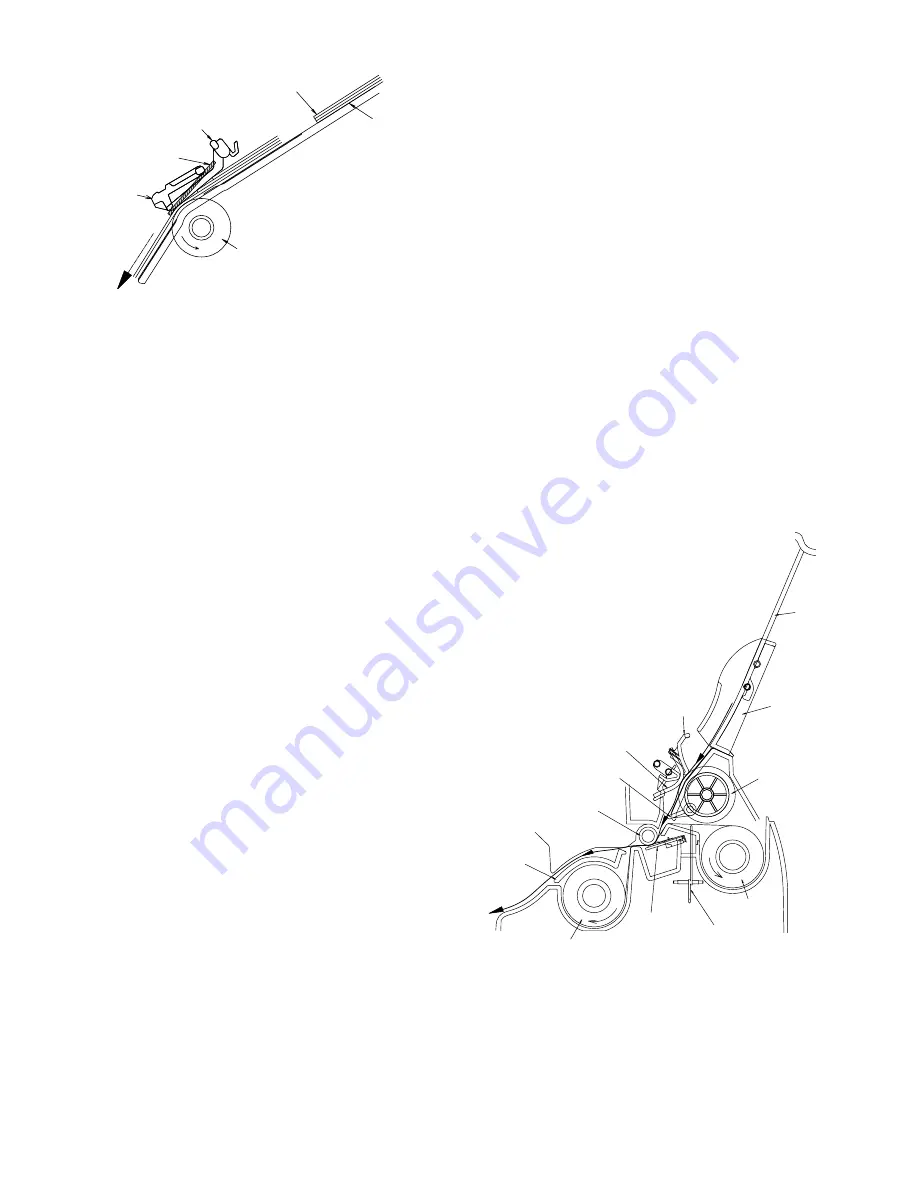

5.3. General view

Fig. 4

Paper feed plate

Paper feed roller

Separate

rubber

Separate

plate

First page of

document

Back of

document

Last page of

document

Fig. 5

Paper

tray

extension

(Accessory)

Paper

tray ass'y

(Accessory)

Release lever

P-IN sensor lever

(Upper)

Film sensor lever

Thermal head

Platen roller

PU roller

Imaging film

(Supply side)

Imaging film

(Take-up side)

Separate rubber

Feed plate