21

VC-A412U/A413U

VC-H812U/H813U

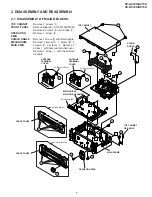

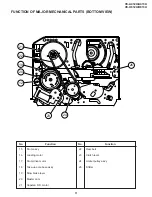

Figure 4-24.

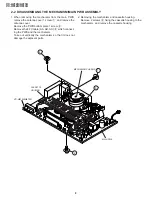

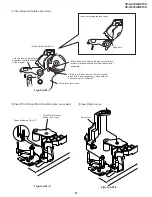

• Replacement

1. Solder the removed PWB to the new head assembly.

2. Adjust the height from the A/C head arm (lower surface)

to the A/C head plate to 10.8mm with slide calipers. (3

places of azimuth screw section, tilt screw section and A/

C head front section) (See the figure below.)

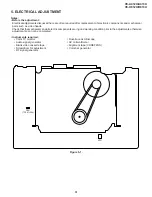

3. Align the left end of gear of A/C head arm with the

punched mark of chassis, tentatively tighten the screws

1

and

2

so as to ensure smooth motion of A/C head

arm. Tentative tightening torque must be 0.15 to 0.20

N·m (1.5 to 2.0kgf·cm).

4-15. REPLACEMENT OF A/C (Audio/Control)

HEAD

1. Remove the cassette housing control assembly.

2. In unloading state unplug the power cord.

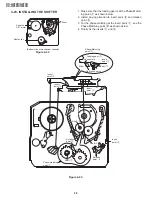

• Removal

1. Remove the screws

123

, Azimuth screw, Tilt screw.

2. Unsolder the PWB fitted to the A/C head.

Notes:

1. When replacing, never touch the head. If you touched,

clean with the cleaning liquid.

2. When removing the screw

3

, take care so that the

spring may out.

New A/C head ass'y

A/C head PWB

2

Spring

1

Solder

Never touch the head

10.8mm

10.8mm

Azimuth screw

Height screw

Tilt screw

A/C head plate

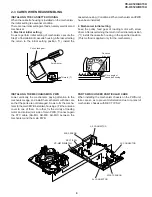

Figure 4-25.

Note:

1. If the screws

1

and

2

are tighten tentatively too loose,

the azimuth and height of A/C head may change when

they are finally tightened. Therefore care must be taken.

2. After completion of A/C head be sure to adjust tape

running. (Execute the running adjustment by the method

described in 4-18.)

1

2

3

Height screw

Figure 4-23.

3

Left end of A/C head arm gear

Punched line mark on chassis