Ref. No.

Part No.

★

Description

Code

Ref. No.

Part No.

★

Description

Code

83

VC-A560U(A)/A560U/A560U(B)

VC-H960U/H960U(B)/H961U

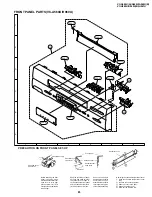

PRECAUTION ON FRONT PANEL SET-UP

Cassette cover

Cassette cover

open lever

Cassette housing

Cassette cover

open lever

Cassette cover

open lever

Cassette cover

About 45

°

Front panel

1

5

2

4

3

Removing the cassette compartment cover.

1

Open the cassette compartment cover

fully.

2

Remove the center positioner.

3

Slide the cover to the right.

4

Slightly bend the cover.

5

Draw out the left-side rod.

Do not mount the front

panel with the cassette

cover tilted too open.

Otherwise the cassette

cover might wrongly run

on the cassette housing.

Keep the cassette over about

45

°

open and make sure that

the cassette cover open le-

ver is between the front panel

and the cassette cover. Now

fix the front panel in place.

Before attaching the front

panel in position, make

sure that the cassette cover

open lever is in its right

place (lower-most). If it is

out of position, push it down

with a finger.

A

B

C

D

E

F

1

2

3

4

5

6

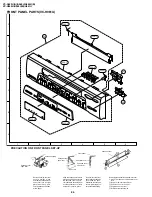

FRONT PANEL PARTS(VC-A560U/H960U)

500

500-1

500-2

500-6

500-10

500-7

500-3

500-12

500-11

501

502