18

VC-AA350A/L/M/W

VC-AA352W,AA360A,AA370A

VC-AA550A/L/W,AA560A,AA570A

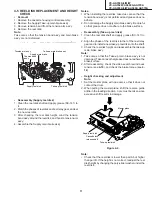

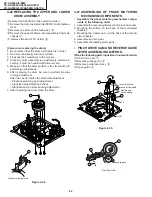

4-17 ADJUSTMENT OF TAPE DRIVE TRAIN

1. Tape run rough adjustment

1

Check and adjust the position of the tension pole.

(See 4-12.)

2

Check and adjust the video search rewind back

tension. (See 4-10.)

3

Connect the oscilloscope to the test point for PB ATR

signal output (TP201). Set the synchronism of the

oscilloscope to EXT. The PB ATR signal is to be

triggered by the head switching pulse (TP202).

4

Set the alignment tape (VROCPSV) to play.

Figure 4-26.

5

Press the tracking button (+), (–) and change the

ATR signal waveform from max to min and from min

to max. At this time make sure that the ATR signal

waveform changes nearly parallel.

6

Unless the ATR signal waveform changes nearly

parallel, adjust the height of supply side and take-up

side guide roller so that the envelope waveform

changes nearly parallel. (For ATR signal adjustment

procedure refer to Figure 4-30.)

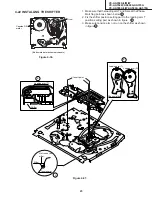

7

Turn the tilt screw to remove the tape crease at the

fixing guide flange.

Playback the tape and check for tape crease at the

fixing guide flange.

(1) If there is no tape crease

Turn the tilt screw clockwise so that tape crease

appears once at the flange, and then return the tilt

screw so that the crease disappears.

(2) If there is tape crease

Turn counterclockwise the tilt screw so that the

tape crease disappears.

(Reference) If the tilt screw is turned clockwise

crease appears at the lower flange.

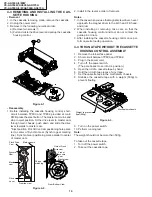

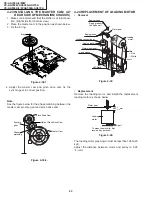

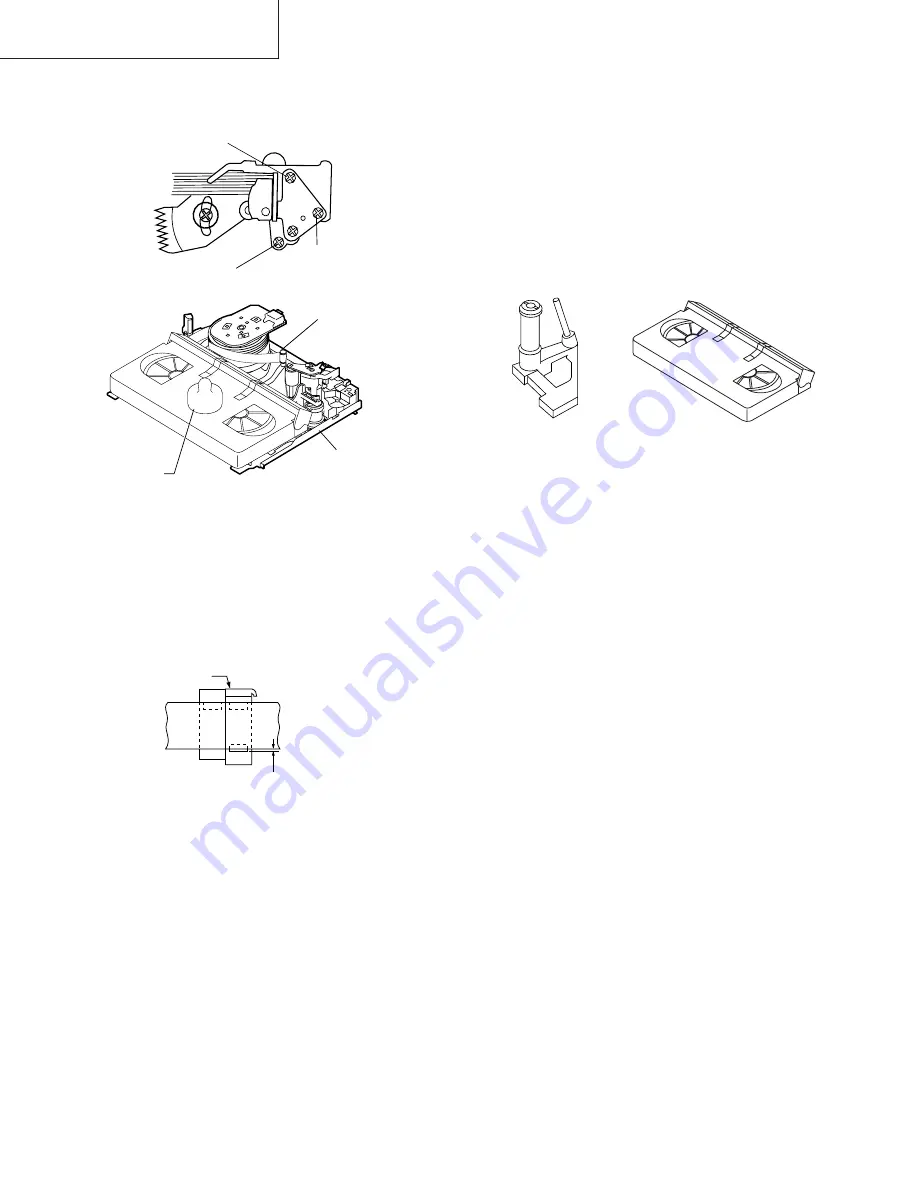

Guide roller

Cassette Tape

Figure 4-24.

Figure 4-25.

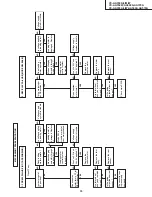

Tape

0.3mm

A/C head

• Adjustment

Adjust the height screw

visually so that the control head is

visible 0.3mm below the bottom of the tape.

1. Set the cassette tape in the unit.

2. Press the PLAY button to put the unit in the playback

mode.

3. Roughly adjust the height of the A/C head by turning the

height screw until the tape is in the position shown

below.

4-16 A/C HEAD HEIGHT ROUGH ADJUSTMENT

• Setting

Mechanism chassis

Cassette tape

Height screw

TiH screw

Azimuth screw

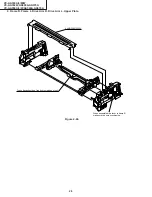

5

00g

Weight to prevent

float (500g)