19

VC-AA350A/L/M/W

VC-AA352W,AA360A,AA370A

VC-AA550A/L/W,AA560A,AA570A

Notes:

1. Previously set the tracking control in the center position,

and adjust the ATR signal waveform to maximum with X

value adjustment nut. Thereby the tape run rough ad-

justment is facilitated.

2. Especially the outlet side ATR signal waveform must

have higher flatness.

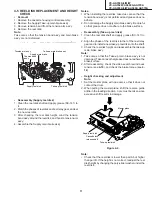

2. Adjustment of A/C head height and azimuth

1

Perform the initial setting of A/C head position by the

method stated in "4-15 Replacement 3".

2

Connect the oscilloscope to the audio output termi-

nal.

3

Using the alignment tape in which 1 kHz linear audio

signal has been recorded, adjust the height screw so

as to get max audio output.

4

Using the alignment tape in which 7 kHz linear audio

signal has been recorded, adjust the azimuth screw

so as to get max audio output.

5

The adjustment of

3

and

4

twice or three times

repeat, and finally adjust

4

.

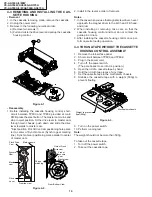

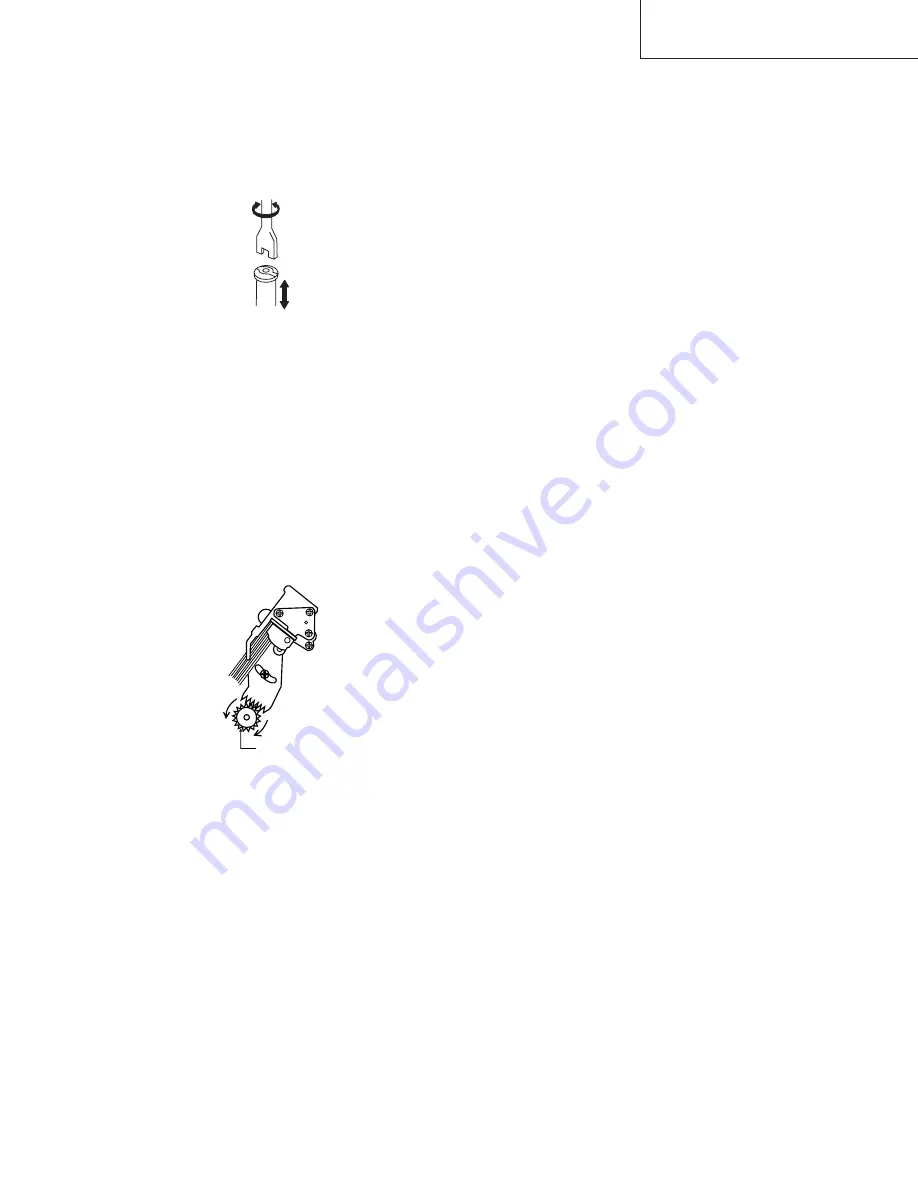

Figure 4-27.

For X value adjustment

Adjust the X value, turning the gear-

type screwdriver.

Figure 4-28.

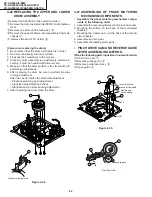

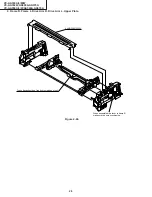

3. Tape run adjustment

1

Connect the oscilloscope to PB ATR signal output

test point, set oscilloscope sync to EXT, trigger-input

the PB CHROMA signal (head switching pulse).

2

Rough adjustment of X value

Tentatively fix A/C head arm screws

1

by the method

described in 4-15 "Replacement 3".

Playback the alignment tape (VROCPSV) and

shortcircuit between TP801 and TP802. As a result

the auto-tracking is automatically cancelled, so that

the X value adjustment mode is set.

Move the A/C head with the X value adjustment gear

driver (JiGDRiVER-6) by the method shown in Fig-

ure 4-33, and adjust the A/C head so as to get the

maximum ATR signal waveform. (Note: When the A/

C head is adjusted, adjust so that the maximum ATR

signal waveform is obtained nearest the position of

initial setting made in 4-15.)