VC-V50S

VC-V80T

VC-V91T

16

• Remove the cassette housing control assembly.

• After short-circuiting TP802 provided at the center

(facing to the main PWB), plug in the power cord.

• Setting

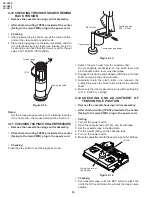

1. Set a torque gauge to zero on the scale. Place it on the

supply reel disk.

2. Switch from the FF mode to the STOP mode.

3. Disconnect the power cord.

• Checking

Turn the torque gauge at a rate of about one turn/2 sec

in the CW direction/CCW direction with respect to the

supply reel disk so that the reel disk and torque gauge

pointer rotate at equal speed, and make sure that the

value is within the setting (CW direction: 4.9 to 13.7mN·m

(50 to 140gf·cm); CCW direction: 2.9 to 9.8mN·m (30 to

100gf·cm).

• Adjustment

1. If the indication of torque cassette meter is lower than

the setting, shift the tension spring engagement to the

part A.

2. If the indication of torque cassette meter is higher than

the setting, shift the tension spring engagement to the

part B.

• Checking the brake torque at the take-up side

Figure 4-22.

CCW: 4.9~13.7mN

⋅

m (50~140gf

⋅

cm)

CW:

3.9~10.8mN

⋅

m (40~110gf

⋅

cm)

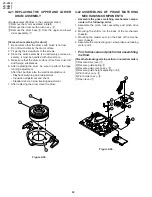

Figure 4-20.

4-14 CHECKING THE BRAKE TORQUE

• Checking the brake torque at the supply side

CCW: 2.9~9.8mN

⋅

m (30~100gf

⋅

cm)

CW:

4.9~13.7mN

⋅

m (50~140gf

⋅

cm)

Figure 4-21.

Tension arm

Tension spring

CW

CCW

CW

Supply reel disk

Torque gauge

Torque gauge

CCW

Take-up reel

disk

A

B

• Remove the cassette housing control assembly.

• After short-circuiting TP802 provided at the center

(facing to the main PWB), plug in the power cord.

• Setting

1. Switch from the FF mode to the STOP mode.

2. Disconnect the power cord.

3. Set a torque gauge to zero on the scale. Place it on the

take-up reel disk.

• Checking

1. Turn the torque gauge at a rate of about one turn/2 sec

in the CCW direction/CW direction so that the reel disk

and torque gauge pointer rotates at equal speed and

make sure that the value is within the setting (CCW

direction: 4.9 to 13.7mN·m (50 to 140gf·cm), CW direc-

tion: 3.9 to 10.8 mN·m (40 to 110gf·cm).

2. Adjustment of the brake torque at the supply side and the

take-up side

• Unless the supply side brake torque or take-up side

brake torque is within the setting, clean the felt surface

of reel disk (supply, take-up) brake lever, check again

the brake torque.

• If value cannot be set within the setting yet, replace the

main brake ass'y or main brake spring.