Summary of Contents for Z-50

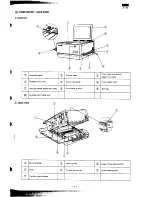

Page 60: ... z m F 1 a I m I v I m I N I I 3 ...

Page 61: ... I I 1 I I I 1 1 I I I 39 ...

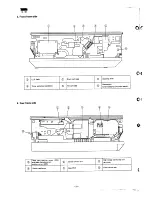

Page 62: ...z a I L m I I NOISE I 6K I m ...

Page 63: ... z m r 2 2 z i w I Iill m i i 4 L 13 2 11 0 9 _ a 41 ...

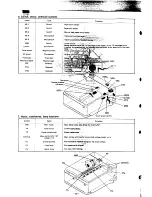

Page 64: ...z a 1 42 ...

Page 65: ... r b e w I m I T I m I N I I I I J L _____ _ 4 II H ZD I 0 u ...

Page 66: ...z a m m I I 44 A f 5 5 ...

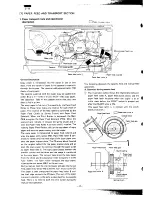

Page 67: ...z m a z u 1 I I Q e ...

Page 69: ... 4 L 1 47 ...

Page 70: ...z s L 1 I c ...

Page 71: ... W m 6V I L I L i 5 7 TY w z ...