[6] COPY PROCESS

1. Copy process composition

Drum base

An OPC drum is used for the photoconductor.

(Structure of the OPC drum layers)

Carrier Transfer layer

(About 20µm)

OPC layer

Carrier Generation layer

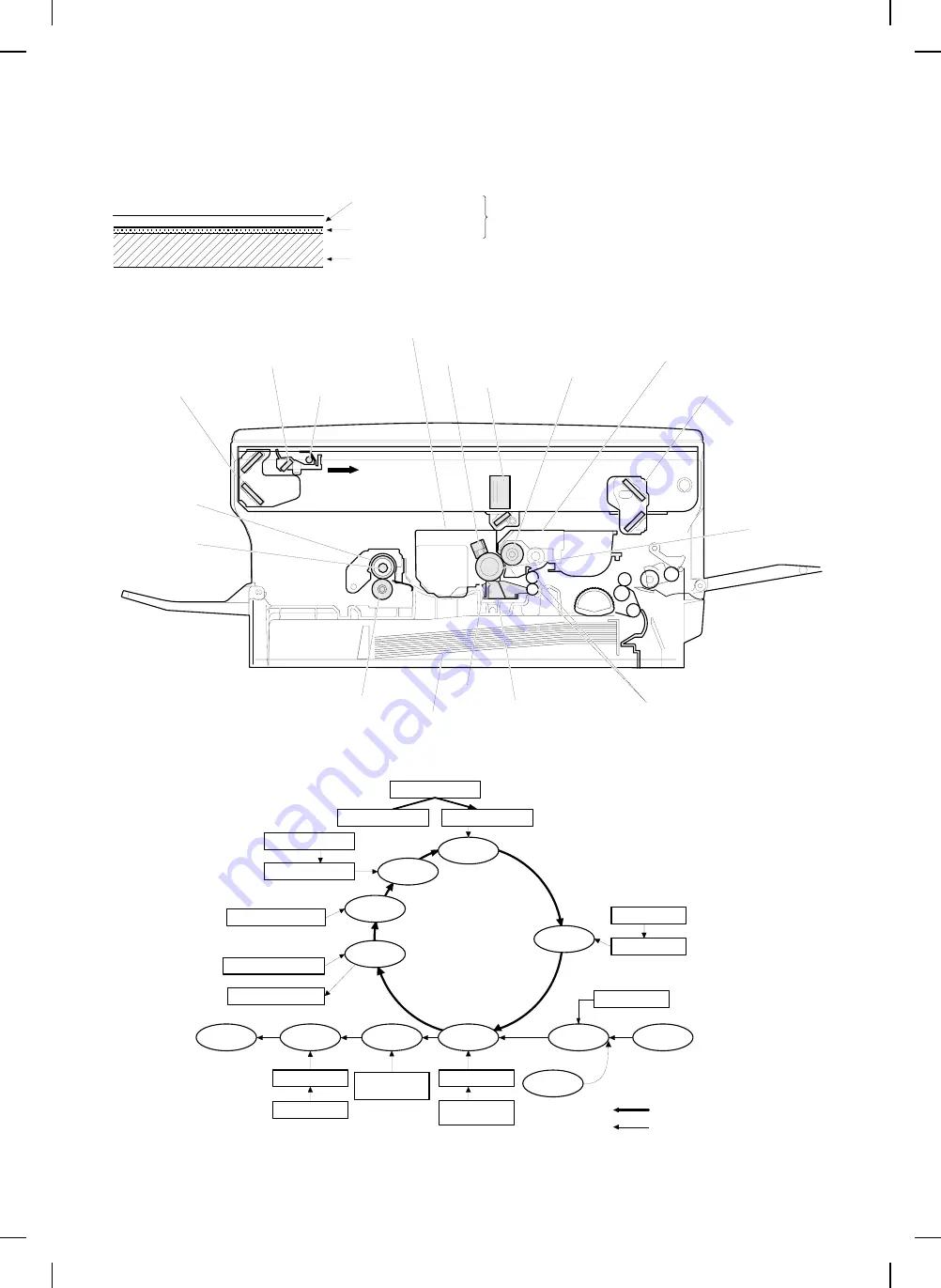

No. 2/No. 3 mirror unit

No. 1 mirror

Copy lamp

Drum cartridge

Main charger

Lens

MG roller

TD cartridge

No. 4/No. 5 mirror unit

Drum

Resist roller

Transfer unit

Separation

electrode

Paper tray

Lower heat roller

Heater lamp

Upper heat roller

Exposure

Main high voltage unit

Main corona

Charge

Discharge

Drum

Cleaning

Cleaning blade

Waste toner collection

Paper exit

Fusing

Separation

Heat roller

Heater lamp

Transfer

Transfer corona

Transfer high

voltage unit

Developing

Toner

Developer

Image forming process

Sync with

drum

Original

Copy lamp

Mirror/Lens

Separation

electrode

paper feed

Manual

paper feed

Paper transport route

Discharge lamp

Resist roller

Copy process flow

Tray

6 – 1

www.freeservicemanuals.info

1/11/16

Published in Heiloo, Holland.