15

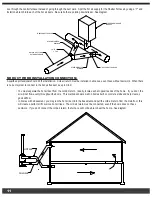

Creosote Prevention:

To help prevent the formation of creosote within the flue, ALWAYS BURN DRY, SEASONED WOOD. Dry wood burns hotter,

allowing flue gases to maintain temperatures above 212°F which should reduce the formation of creosote in the chimney. If the

flue gas temperature falls below 212°F, condensation occurs causing creosote formation and accumulation within the chimney.

As an added precaution, periodic chimney inspections are recommended during the heating season to determine if creosote formation

has occurred. For safety and efficiency, it is recommended that the chimney system be inspected and cleaned prior to each heating

season.

Power Failure:

In case of power failure, to prevent your Shelter Furnace from over-heating and causing damage to the electrical components, follow

these steps:

• Make sure the ash door is closed.

• Close the slide cover on the side of the draft motor.

• Do NOT add more fuel to the firebox.

There is no warranty on electrical components damaged due to power failure.

CAUTION:

• INSPECT FLUE PIPES, FIREBOX, STOVE PIPE, CHIMNEY AND DRAFT BLOWER JOINTS AND SEALS REGULARLY TO

ENSURE THAT SMOKE AND FLUE GASES ARE NOT DRAWING INTO, AND CIRCULATED BY THE

AIR-CIRCULATION SYSTEM.

• CLEANING OF THE FIREBOX, STOVE PIPE, CHIMNEY AND DRAFT BLOWER (IF USED), IS ESPECIALLY IMPORTANT

AT THE END OF THE HEATING SEASON TO MINIMIZE CORROSION DURING THE SUMMER MONTHS CAUSED BY

THE ACCUMULATED ASH.

• Do not use chemicals to start the fire.

• Do not burn garbage, gasoline, naphtha, engine oil, or other flammable liquids/inappropriate materials.

Maintaining

Your

Furnace:

At the beginning of each heating season, take time to thoroughly check your furnace and chimney system. Make sure there are no

leaks where the metal panels are joined or at the caulk lines. Should you find a leak, high-temp silicone will correct the problem. Check

the door for signs of rust. Should rust develop, lightly sand, with sandpaper or steel wool, the surface and follow up with black, high

temperature paint to keep the door looking new. Check the gaskets, if they are frayed and burnt, replace the gasket. Check the firebricks

for breakage or crumbling, and replace as needed. Check the chimney pipe for signs of creosote formation, if you find creosote,

thoroughly clean the chimney system replacing the chimney cap securely so rain or snow does not run down the chimney into the firebox.

If the cap is removed for any length of time when the furnace is not in use, cover the pipe so no moisture gets into the firebox. Check the

chimney cap for holes or loosened connections, replace and secure as necessary. Check the grates for signs of wear and replace as

needed. Check the heat duct and cold air return to be sure they have not become loose or been damaged. If so, tighten or replace as

needed. Check ductwork for any air leaks. Remove any accumulated ashes at the end of the season. By following these procedures,

your furnace will provide many years of trouble-free service. Door seals should be checked annually to make sure that a good seal will

ensure complete combustion and high efficiency.

IMPORTANT: FOR TECHNICAL SUPPORT OR CUSTOMER SERVICE

ISSUES, DO NOT RETURN TO THE STORE (THE STORE MAY NOT HAVE

REPLACEMENT PARTS), CALL 1-800-875-4788.