Operating manual: Mobile speciality pump CHIEMSEE

SHG

S

PECHTENHAUSER

H

OCHWASSER

-

UND

G

EWÄSSERSCHUTZ

G

MB

H

Gewerbestraße 3, D-86875 Waal, Germany

www.spechtenhauser.de

Tel.:

+49 (0)8246.9695-20

shg@spechtenhauser.de

Fax:

+49 (0)8246.9695-24

0119BACHE28

12

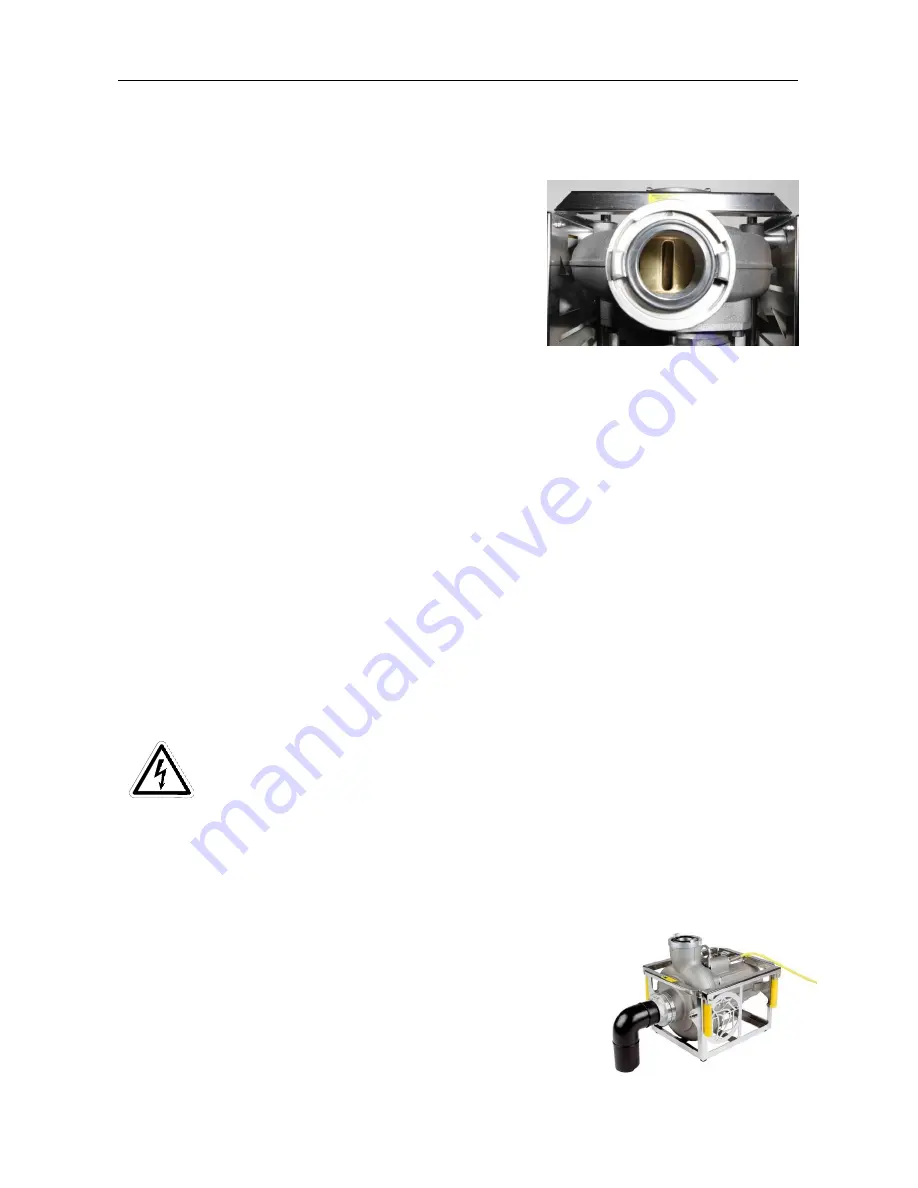

Image 2.2: Cleani

ng slot on „12 o’clock position“

12. Clean the pump after each use, particularly after using it with muddy liquid. Secure the

pump against restarting. Before cleaning remove the motor protection plug and secure

the pump and the motor protection plug against accidental restarting and plugging.

Use a high-pressure cleaner first, to clean the pump and in particular the impeller. To

clean the impeller, turn the cleaning slot of

the impeller to the “12 o’clock position” so

that the cleaning slot is visible on the outlet

side of the pump (see image 2.2). Use the

high-pressure cleaner to spray directly into

the cleaning slot, to clean the impeller thor-

oughly. Then let the pump run for around

10 minutes in a basin with clean water. Fi-

nally, the pump must be completely

drained.

4.3 Series connection of CHIEMSEE pumps

To achieve pumping heights of over 12 m, series connection of CHIEMSEE pumps is pos-

sible. With this, the pressure side of the first CHIEMSEE is connected to the next

CHIEMSEE over a dimensionally flexible hose.

4.4 Low-level pumping

In normal operation, the liquid is pumped to the top of the intake nozzle. The pump then

intakes air and the pumping flow breaks off. To pump fluids up to a residual water level of

a few millimetres, the flat intake nozzle has to be mounted to the suction-side fixed coupling

(see Image 2a).

Caution CHIEMSEE H:

In case of high fluid temperatures of >80°C cavitation might arise during low-level pumping.

In this case the fluid has to be cooled with cold water.

If low-level pumping is to be carried out, the following points are to be observed:

1. Pump the medium according to section 4.2 of this user manual without flat intake nozzle

(with the intake nozzle facing upwards) until the pump intakes air.

2. Now switch the pump off and remove the motor protection plug. Secure the pump and

the motor protection plug against accidental restarting and plugging.

Danger from electric shock:

Only carry out work on the pump when the pump is disconnected from the network by

removing the motor protection plug from the power supply. Prevent accidental restart

and plugging of the pump and the motor protection plug by taking appropriate measures.

3. Now mount the flat intake nozzle to the suction-side fixed coupling. Use a coupling

spanner for this. Turn the curve clockwise until it is vertical and facing downwards (i.e.

up to the limit stop). Ensure that no stones or other hard objects, such as pond foils, can

be taken in!

4. Now plug the motor protection plug into the socket again and switch the pump on again.

5. If the flat intake nozzle gets stuck on solids, first turn

off the pump, then pull the motor protection plug and

remove the solids from the intake nozzle.

6. Pump the liquid until the pump intakes air. Switch

the pump off again.

As the intake nozzle reach until about 1 cm above the

ground, it is possible that there are still floating solids in

Image 2.3: CHIEMSEE

with flat intake nozzle

Summary of Contents for CHIEMSEE A

Page 32: ......