193

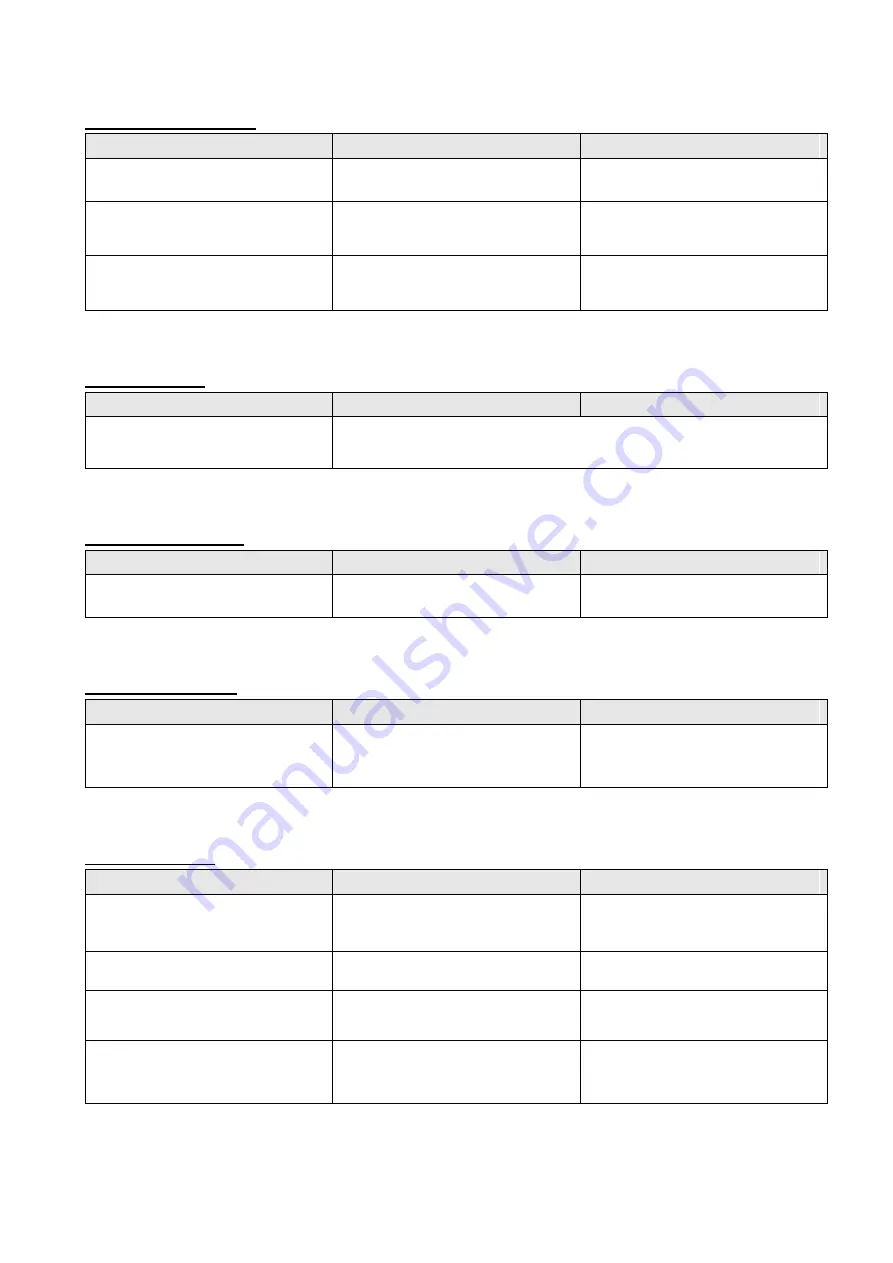

AL0B Encoder error 1

Cause

Inspection

Remedy

Wirings are in wrong sequence.

Check if wirings sequence is correct

or not.

Correct the wirings.

CN2 connector is loosened or

disconnected.

Check if CN2 connector is loosen or

disconnected.

Re-connect CN2 connector.

Encoder faulty

Check the encoder feedback pulses

continuity of motor while Servo OFF

Contact agent for proper service.

AL0D Fan error

Cause

Inspection

Remedy

Cooling fan stops working.

Change the fan by user or contact agent for proper service.

AL0E IGBT overheat

Cause

Inspection

Remedy

Operate the drive in over-rate duty

continuously.

Check if mechanism is overload or

motor current is huge.

Reduce load, or to use servo drive

and motor provide larger output.

AL0F Memory error

Cause

Inspection

Remedy

Data read-out/write-in abnormally.

To execute the parameter recovery

or power on reset and check if it still

null.

Contact agent for proper service.

AL10 Overload 2

Cause

Inspection

Remedy

Mechanical impact

Check if the moving route is proper. 1. Correct the moving route.

2. Install limit switches.

Wrong connection of servo motor.

Check the wirings.

Correct the wirings.

Mechanism vibration.

Check if mechanism is instable and

humming.

1. Change response level setting.

2.

Make gain adjustment manually.

Encoder faulty.

To rotate motor shaft and check the

continuity of encoder feedback

pulses while Servo OFF.

Contact agent for proper service.

Summary of Contents for SDE Series

Page 13: ...5 1 6 Function block diagram ...

Page 26: ...18 3 3 3 CN1 pin name list ...

Page 223: ...215 SME L040 SME L075 SME L100 SME L150 ...

Page 224: ...216 SME L200 SME L300 SME M100 SME M150 Continuous running range ...

Page 227: ...219 ...

Page 231: ...223 4 Wiring example with peripheral equipment CN2 Encoder socket ...

Page 242: ...234 12 4 Version information Version V1 01 Issue date Aug 2017 Proofreader Yaochou Shu ...