37

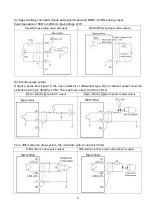

3.8. Standard wiring method

Any person who does the wiring job should be fully competent.

Before wiring, turn off the power and wait for 10 minutes or more until the

charge LED turns off. Otherwise, an electric shock may occur.

Ground the servo drive and servo motor tightly.

Not to wire the servo amplifier and servo motor until they have been installed.

Otherwise, it may cause an electric shock.

The cable should not be damaged, stressed, loaded, or pinched. Otherwise, it

may cause an electric shock

.

The wires between the servo drive and servo motor should be correctly.

Otherwise, the servo motor may run unexpectedly.

The wirings of cables and terminals should be correct, otherwise a burst,

malfunction, etc. may occur.

Ensure that polarity (+/-) is correct. Otherwise, a burst, malfunction, etc. may

occur.

The surge absorbing diode installed to the DC relay for output control should

be proper in the specified direction. servo motor can not be connected to the

commercial power directly. Otherwise, the emergency stop and other

protective circuits may not work.

The electronic equipment around the servo drive may be interfered, please

use the EMI suppression filter to improve.

Not to connect a power factor capacitor, surge absorber or radio noise filter

with the power line of the servo motor.

When using a regenerative resistor, switch power off by AL04 signal.

Otherwise, a brake IGBT fault may cause a fire due to overheated the

regenerative resistor.

Do not modify the servo drive or servo motor.

Summary of Contents for SDE Series

Page 13: ...5 1 6 Function block diagram ...

Page 26: ...18 3 3 3 CN1 pin name list ...

Page 223: ...215 SME L040 SME L075 SME L100 SME L150 ...

Page 224: ...216 SME L200 SME L300 SME M100 SME M150 Continuous running range ...

Page 227: ...219 ...

Page 231: ...223 4 Wiring example with peripheral equipment CN2 Encoder socket ...

Page 242: ...234 12 4 Version information Version V1 01 Issue date Aug 2017 Proofreader Yaochou Shu ...