Parameter Description

Parameters

145

<Setting>

• When the operation frequency is smaller than P.2, the operation frequency will be equal to

the minimum limited frequency P.2. When the operation frequency is larger than P.1, the

operation frequency will be equal to the maximum limited frequency P.1

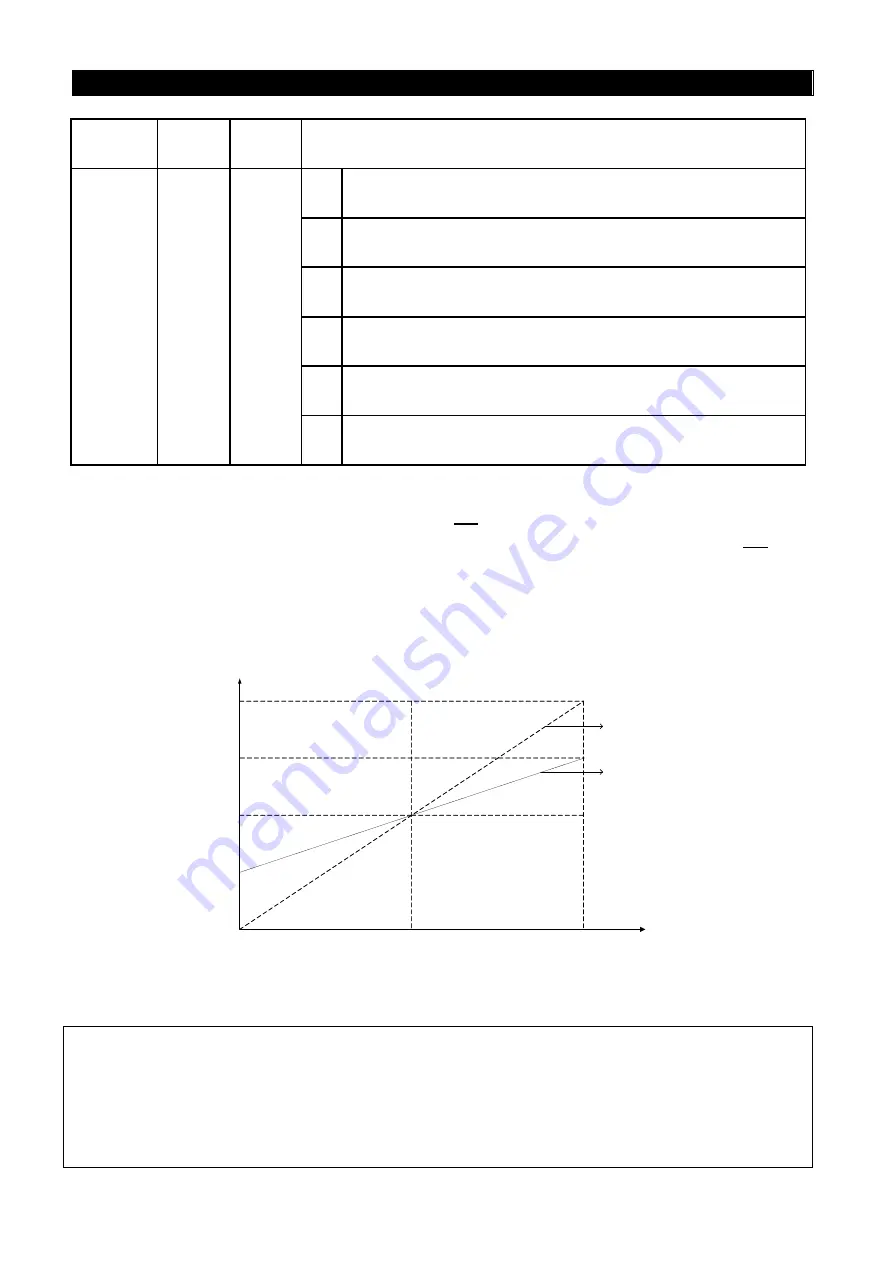

• After multiplying the setting frequency by the set value of P.185, then addition and

subtraction can be performed as following shows:

For example: When the setting frequency is 50Hz, P.185=50% and the external analog

input signal is 0~10V.

25HZ

0V

5V

10V

50HZ

75HZ

100HZ

The target frequency

Given by the voltage

of terminal 2-5

P.185=100%

P.185=50%

In the above figure, when 0V is given, the target frequency is 50Hz - (50Hz × 50%) = 25Hz;

When 5V is given, the target frequency is 50Hz - (50Hz × 0%) = 50Hz;

When 10V is given, the target frequency is 50Hz + (50Hz × 50%) = 75Hz.

Parameter

Factory

setting

Setting

range

Remarks

240

0

0~9

4

operation frequency = basic frequency - auxiliary

frequency (given by the 4-5 terminal)

5

operation frequency = given by the terminal 2-5 as the

proportion linkage signal

6

operation frequency = given by the terminal 4-5 as the

proportion linkage signal

7

operation frequency = given by the terminal 1-5 as the

proportion linkage signal

8

operation frequency = basic frequency + auxiliary

frequency (given by the terminal 1-5)

9

operation frequency = basic frequency - auxiliary

frequency (given by the terminal 1-5)

Note: 1. The basic frequency is set by DU01 which is the target frequency reference source,

communication or multi-speed combination.

2. Please refer to the instruction of P.240 for the proportion linkage signal input.

3. When the analog current/voltage signal of external terminal 4-5 is taken as the proportion linkage

input signal, please refer to the parameter P.17. For the frequency range setting of external

analog signal, please refer to the parameters P.38, P.39, P.509, P.17, P.73, P.530.