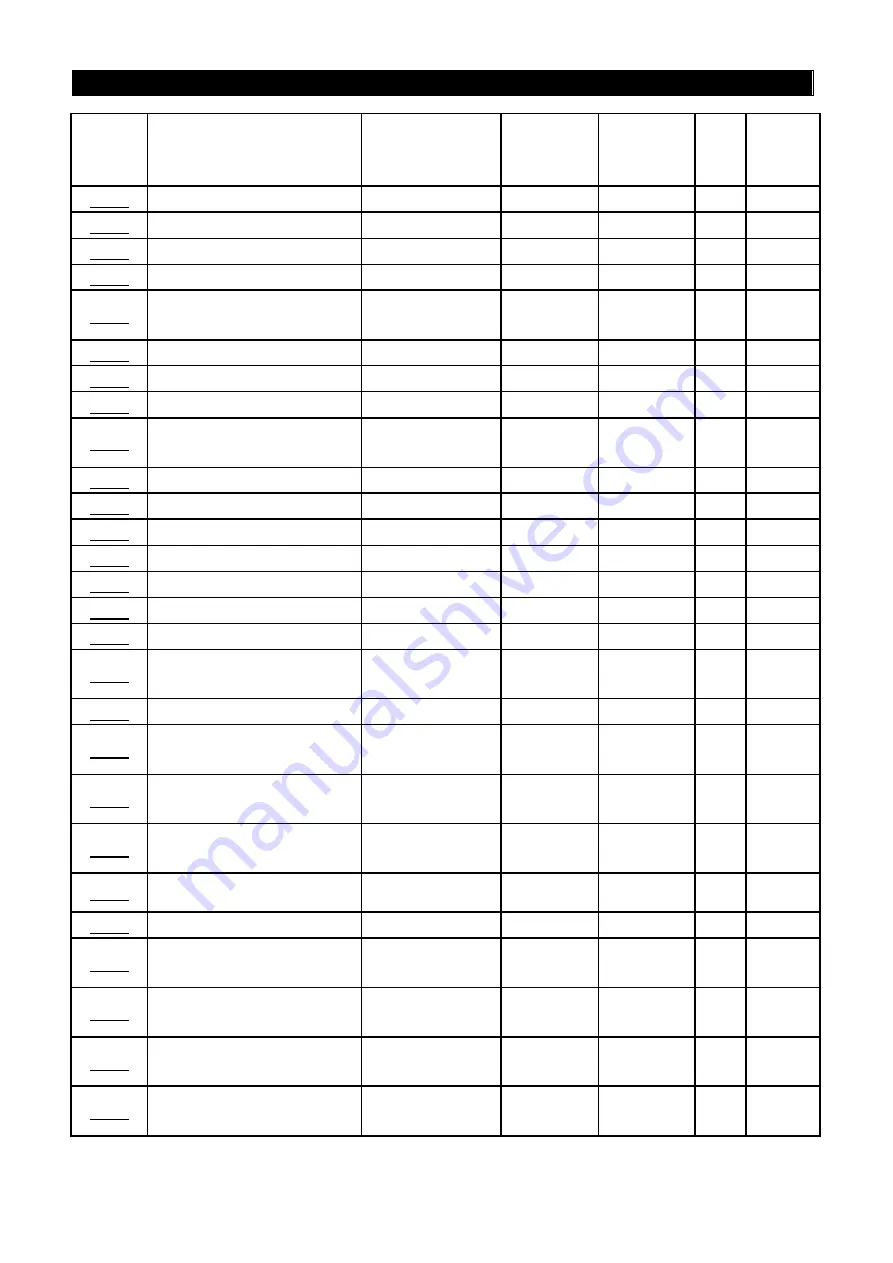

Appendix 1 Parameter Table

Parameter Table

213

Parameter

Number

Name

Setting Range

Minimum

Setting Unit

Default Value

User

Setting

Value

Reference

Page

Initial curling radius source

0~1

1

0

P182

Initial curling radius 1

1~10000mm

1 mm

100 mm

P182

Initial curling radius 2

1~10000mm

1 mm

100 mm

P182

Initial curling radius 3

1~10000mm

1 mm

100 mm

P182

Curling radius filtering

coefficient

0~31

1

0

P182

Current value of curling radius

0~10000mm

1 mm

---

P182

Number of pulses each turn

1~60000

1

1

P182

Number of turns each layer

1~10000

1

1

P182

Material thickness setting

source

0~1

1

0

P182

Material thickness 0

0.01~100.00mm

0.01 mm

0.01 mm

P182

Material thickness 1

0.01~100.00mm

0.01 mm

0.01 mm

P182

Material thickness 2

0.01~100.00mm

0.01 mm

0.01 mm

P182

Material thickness 3

0.01~100.00mm

0.01 mm

0.01 mm

P182

Maximum thickness

0.01~100.00mm

0.01 mm

1.00 mm

P182

Line speed input source

0~2

1

0

P186

Maximum line speed

0.1~6500.0m/min

0.1m/min

1000.0m/min

P186

Minimum line speed for

curling radius calculation

0.1~6500.0m/min

0.1m/min

200.0m/min

P186

Actual line speed

0~6500.0m/min

0.1m/min

---

P186

Inertia self learning torque

setting 1

0.0%~P.632

0.1%

30%

P187

Inertia self learning torque

setting 2

P.631~100%

0.1%

60%

P187

Mechanical inertia

compensation coefficient

0~65535

1

0

P187

Material density

0kg/m

3

~60000kg/m

3

1 kg/m

3

0 kg/m

3

P187

Material width

0~60000mm

1mm

0mm

P187

Fiction compensation

coefficient

0.0%~50.0%

0.1

0

P187

P.637

Material supply interrupt auto

detection function selection

0~1

1

0

P188

P.638

Material supply interrupt auto

detection minimum line speed

0.1~6500.0m/min 0.1m/min

200m/min

P188

P.639

Material supply interrupt auto

detection error range

0.1%~50.0%

0.1%

10.0%

P188