Parameter Description

Parameters

63

5.7 DC Injection Brake (P.10, P.11 and P.12)

P.10 “DC injection brake operation frequency”

P.11 “DC injection brake operation time”

P.12 “DC injection brake operation voltage”

Parameter

Factory setting

Setting range

Remarks

10

3Hz

0~120Hz

---

11

0.5s

0~60s

---

12

4% (7.5kW or below)

0~30%

---

2%(11kW~55kW)

1% (75kW or above)

<Setting>

• After a stop signal is put in (please refer to Chapter 4 for the primary operation of motor

activation and stop), the output frequency of the inverter will decrease gradually. In case

the output frequency reaches the “DC injection brake operation frequency (P.10),” the DC

injection brake will be activated.

• During DC injection brake, a DC voltage will be injected into the motor windings by the

inverter, which is used to lock the motor rotor. This voltage is called “DC injection brake

operation voltage (P.12)”. The larger the P.12 is, the higher the DC brake voltage is, and

the stronger the brake capability is.

• The DC brake operation will last a period (the set value of P.11) to overcome the motor

inertia.

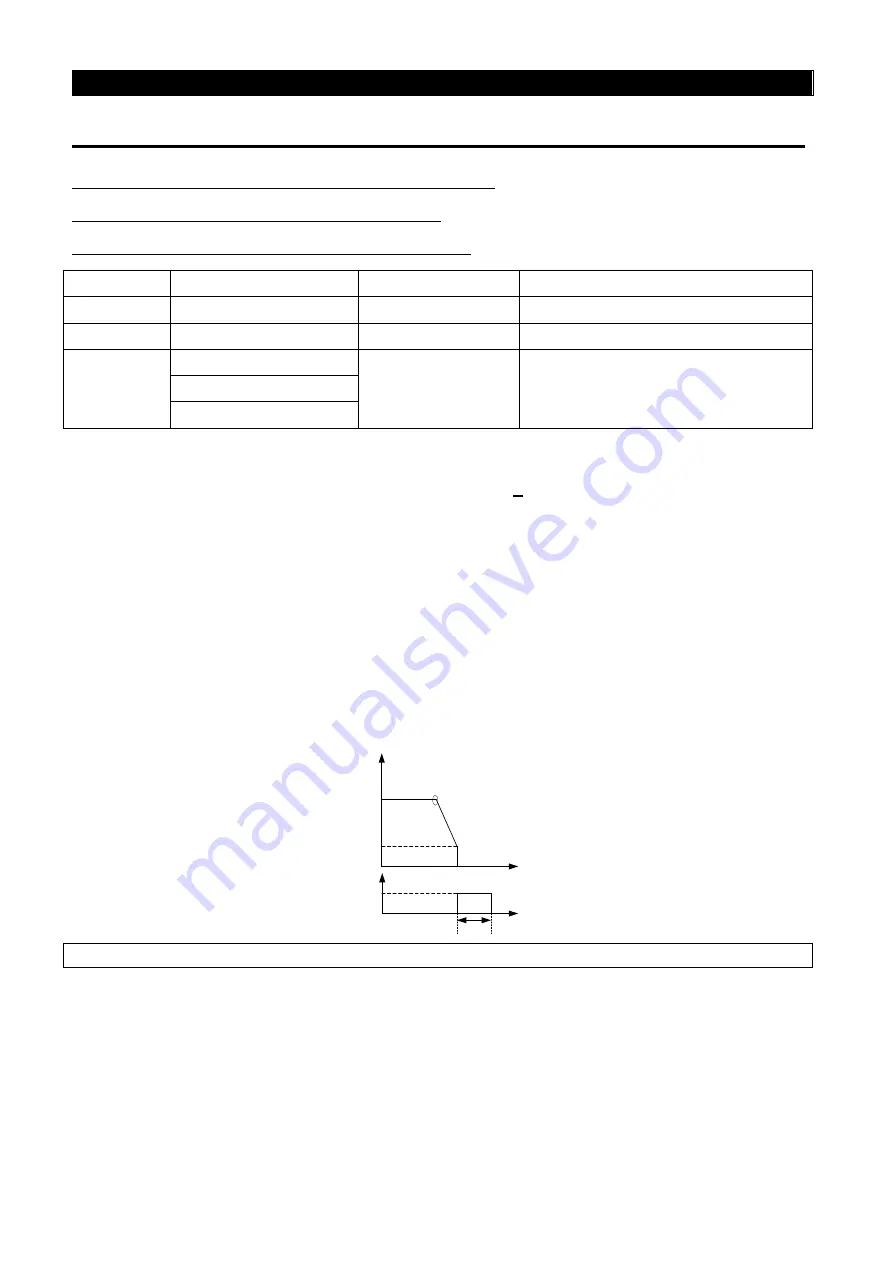

See the figure below:

P.12

Time

P.11

Output

frequency

(

Hz

)

P.10

DC

braking

voltage

Time

Stop signal input

Note: To achieve the optimum control characteristics, P.11 and P.12 should be set properly.