Parameter Description

Parameters

191

• In the process of auto roll alternation, when the torque memory enable signal is valid, the

replacing lower roll inverter will control the torque according to the memory torque at first.

And then after the delay time set by P.647, the output torque will be increased according

to the torque increase proportion set by P.646.

5.9

3

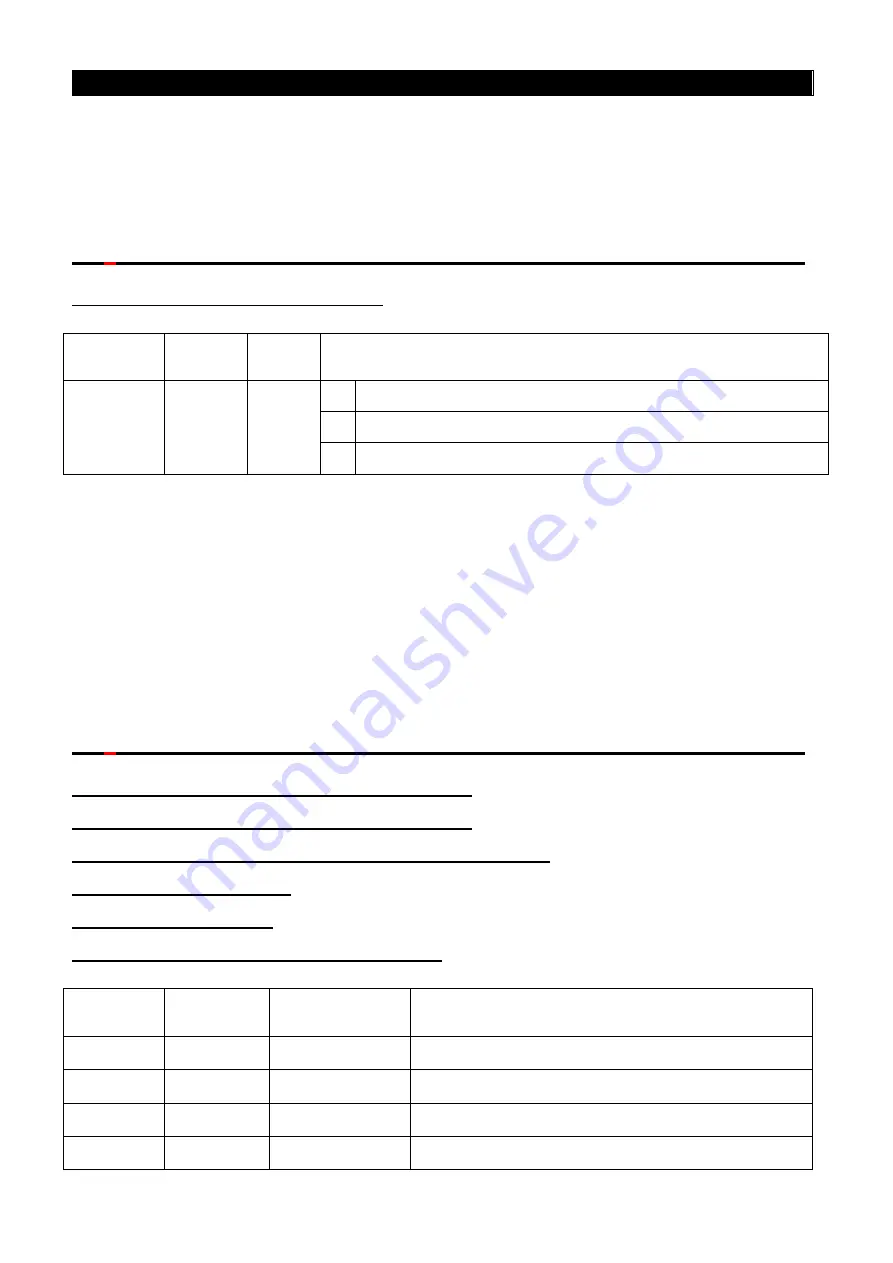

Constant line speed mode parameter (P.656)

P.656 “Line speed setting source”

Parameter

Factory

setting

Setting

range

Remarks

656

0

0~2

0 The line speed setting is invalid

1 The line speed is obtained by analog value or pulse input

2 The line speed is obtained by communication mode

<Setting>

• The parameter is only valid when P.600=4. P.656 is used to select the method or channel

for acquiring the target speed of constant line speed.

1) When P.656=1, the line speed is obtained by analog value or pulse input. The maximum

line speed P.628 must be set correctly now. The maximum of analog value or pulse input

corresponds to the maximum line speed.

2) When P.656=2, the line speed is obtained by communication mode. It is set by the

communication address 100BH which setting range is 0~6500.0m/min.

5.8

9

Tension compensation (P.631~P.636)

P.631 “Inertia self learning torque setting 1”

P.632 “Inertia self learning torque setting 2”

P.633 “Mechanical inertia compensation coefficient”

P.634 “Material density”

P.635 “Material width”

P.636 “Fiction compensation coefficient”

Parameter

Factory

setting

Setting range

Remarks

631

30.0%

0.0%~P.632

Inertia self learning torque setting 1

632

60.0%

P.631~100.0% Inertia self learning torque setting 2

633

0

0~65535

Mechanical inertia compensation coefficient

634

0

0~60000kg/m

3

Material density