Thank you very much for choosing our products, and please read over the operating manual

and keep it properly prior to installation and use.

Warning

I. Product Introduction

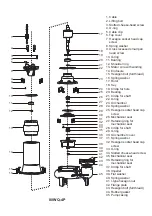

Submersible electric sewage pumps (hereinafter referred to as the “electric pumps”)

include WQ(D), WQ(D)-L1, WQ(D)-L2, WQK, WVSD, DWE, WQDS, WQ(D)AS-CB, WQ-

QG, WQ(D)-4P electric pumps. The electric pump is composed of water pump and motor;

located in the upper part of electric pump, motor is single-phase or three-phase

asynchronous motor; located in the lower part of electric pump, water pump is of channel

impeller or vortex impeller-volute structure; mechanical seal and framework oil seal are

adopted between water pump and motor as seal, and “O”-shaped oil resistant rubber seal

rings are adopted at fixed rabbet seals as static seal to ensure the reliability of electric

pump.

This series of electric pumps are widely used in such fields as industry, agriculture,

mining, building construction, and municipal administration and environmental protection,

and pump liquids can contain fiber, scrap paper and other solid particles or soft solids, e.g.

muddy water, grey water, domestic sewage, wastewater, feces and urine, etc., which are

ideal hydraulic equipment for agricultural drainage and irrigation, river/pool dredging, and

field construction, but not for applications with explosion-proof requirements.

II. Operating Conditions

Electric pump shall be able to operate continuously and normally in the following

operating conditions:

1. The temperature of medium is no higher than +40°C;

2. The pH value of medium is 4~10;

3. The maximum density of medium is 1.2*103kg/m3;

4. The immersion depth is no less than 0.5m and no more than 5m.

• The Electric Pump must be grounded reliably before use, and shall be

equipped with an electrical leakage protection device;

• It's strictly prohibited to touch the Electric Pump during operation;

• It's strictly prohibited to run the Electric Pump without water;

• For three phase-motors with integrated thermal protector shut down due to

overload or overheating, it is NOT allowed to re-connect the power until

motor cooling for more than 10 minutes.