6

Assembly

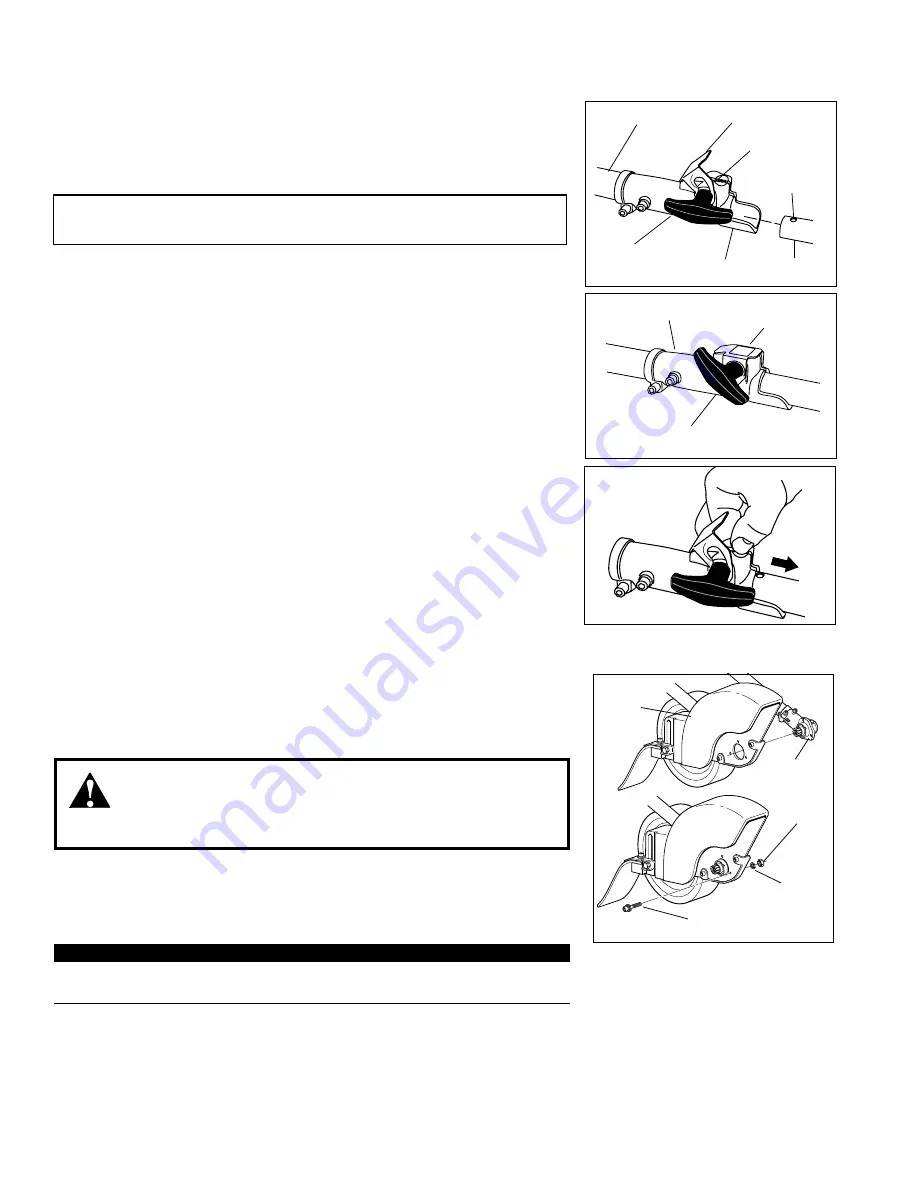

Mount the Cutting Attachment Shield on the

Gearcase

Remove the shaft bolt, bolt guard, holder A and holder B from the gearcase.

1.

Align the cutting attachment shield assembly (A) with the gearcase as shown,

2.

and then fit the shield onto the matching flange (B) on the gearcase.

WARNING!

The edger is intended for right-handed operation only! When cor-

rectly assembled, the cutting attachment shield and shaft must be oriented as

shown.

Install the socket-head screws (C) with washers. Firmly tighten all three

3.

screws.

Install a washer (D) and nut (E) on each of the three screws assembled in

4.

Step 3, then firmly tighten each nut.

IMPORTANT!

The three socket-head screws must be firmly tightened against the cutting attach-

ment shield before installing and tightening the nuts.

26019

A

S

S

E

M

B

L

Y

9

26018

26020

Mount the Edger Blade

1. Install the holder A onto the output

shaft. See Figure 6.

2. Mount the edger blade and holder

B onto the output shaft, and then

install the bolt guard and shaft bolt

(turn bolt counterclockwise to

install). See Figure 6.

3. Align the hole in holder A with the

matched hole in the gearcase, and

then use the hex wrench to

temporarily lock the output shaft.

See Figure 6.

4. Use the combination wrench to

firmly tighten the shaft bolt.

Remove the hex wrench.

See Figure 6.

WARNING!

n

The edger is designed for use

with an edger blade only!

n

Never operate the edger

without the cutting attachment

shield installed and tightly

secured!

Mount the Cutting Attachment

Shield on the Gearcase

1. Remove the shaft bolt, bolt guard,

holder A and holder B from the

gearcase. See Figure 5.

2. Align the cutting attachment shield

assembly with the gearcase as

shown, and then fit the shield onto

the matching flange on the

gearcase. See Figure 5.

WARNING!

The edger is intended for right-

handed operation only! When

correctly assembled, the cutting

attachment shield and shaft

must

be oriented as shown.

3. Install the socket-head screws with

washers, then use the hex wrench

to firmly tighten all three screws.

See Figure 6.

4. Install a washer and nut on each of

the three screws assembled in

Step 3, then firmly tighten each nut.

65010-94010_MLE230_07LP

11/21/01, 11:19 AM

10

A

B

C

D

E

M23004

A

Place the Multipurpose Tool Carrier (A) and the Tool Assembly (B) on a clean,

1.

flat surface so that both assemblies fit end to end. The powerhead assembly

should be facing up, and the tool assembly should be positioned with the lock-

ing hole in the tube (C) end facing up.

CAUTION!

Keep the open ends of the tubes clean and free of Debris!

Slip off the protective cover from the end of the tool, and loosen the coupler

2.

screw knob (D).

Insert the tool assembly into the coupler (E), with the tool decal facing up, until

3.

the line of the decal is flush with the end of the coupler. Twist the tool back and

forth until you are sure it snaps in place by the coupler latch (F).

When the two tube halves are locked together, press down on the spring-

4.

loaded latch protector (G) and tighten the coupler screw knob.

Installing a Tool Attachment

M23005

G

D

E

M23006

B

C

D

E

F

G

Disassembling The Pole Sections

Place the Multipurpose Tool Carrier and the Tool Assembly on a clean, flat sur-

1.

face, loosen the coupler screw knob (D). The spring-loaded coupler protector

(G) should pop up.

Press down on the latch (F) with your finger or thumb. This releases the cou-

2.

pler latch.

Pull the tool assembly (B) out of the coupler (E).

3.

Summary of Contents for 65010

Page 11: ...11...