3

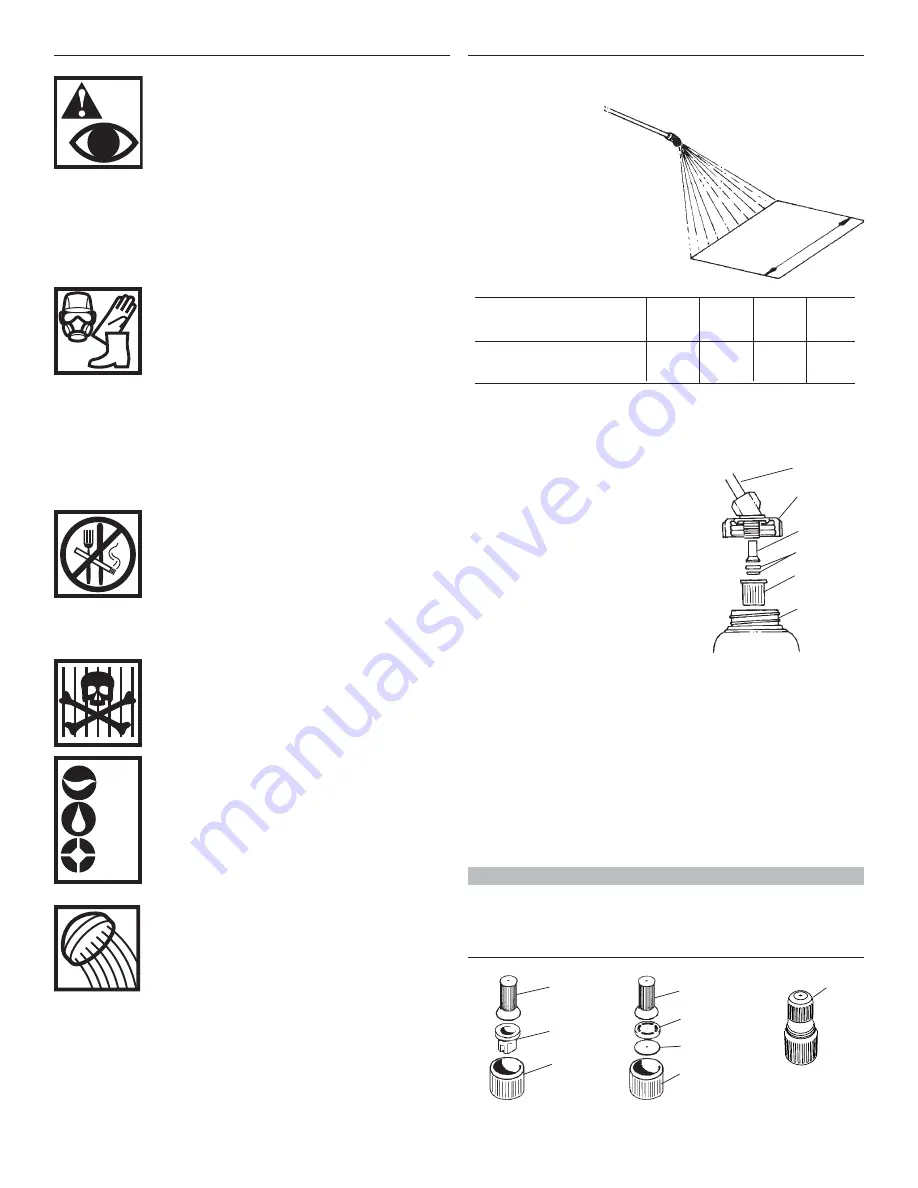

3. Attach the flow calibrator bottle to the wand:

a. Remove the nozzle, cap and filter from the spray wand.

b. Mount the flow calibrator cover

to the spray wand.

c. Reinstall the nozzle, filter and

nozzle cap.

d. Screw the flow calibrator bottle

into the cover.

4. Using the flow calibrator bottle:

a. Operate the pump handle to

maintain spray system pressure as

you would when applying chemi-

cals.

b. Hold the wand at your normal

working position and spray into the bottle while walking the

distance identified in step 2 above.

c. Place the bottle on a level surface and observe the liquid

level visible through the side of the bottle. Match the liquid

level to the l/acre (liter per acre) scale on the calibration

bottle.

d. Multiply the l/acre (liter per acre) reading identified in

step 4-c by .264 to determine your application coverage rate

in gallons per acre.

e. Empty the bottle contents back into the sprayer tank.

NOTE:

For improved accuracy in calibrating your application coverage,

repeat steps 4-a through 4-e and average the results.

Carefully read the labels on chemical containers

prior to use. Chemicals are classified in four

categories of toxicity:

■

Category I, High Toxicity, Red label

■

Category II, Moderate Toxicity, Yellow label

■

Category III, Low Toxicity, Blue label

■

Category IV, Light Toxicity, Green label

There are unique handling recommendations

for each category, and you should familiarize

yourself with them.

Always wear clothing and safety equipment that

will provide appropriate protection against the

materials you are handling. Equipment may

include, but not be limited to:

■

Long sleeve shirt

■

Impermeable apron or coverall

■

Impermeable gloves and boots

■

Wide-brim hat

■

Protective mask equipped with

appropriate filters

Do not eat, drink, or smoke while handling

chemicals or while you are spraying. Always

handle chemicals in a well ventilated area while

wearing appropriate protective clothing and

safety equipment. DO NOT STORE OR TRANS-

PORT CHEMICALS WITH FOOD OR MEDI-

CINES, AND NEVER REUSE A CHEMICAL

CONTAINER FOR ANY OTHER PURPOSE.

Keep chemicals out of the reach of children,

animals, or other unauthorized people. When

not in use, store chemicals in a safe place.

Never blow through nozzles, valve, pipes or any

other component by mouth!

When handling chemicals and when spraying,

make sure you are operating in accordance with

local, state, and federal environmental protec-

tion rules and guidelines. Do not spray in very

hot or windy conditions. DO NOT POLLUTE

THE ENVIRONMENT!

After spray application, take a thoroughly

cleansing shower using plenty of water and

soap, then change into clean clothes. Protective

clothing and safety gear should also be cleaned

after each use. IN CASE OF EXPOSURE TO

DANGEROUS CHEMICALS, seek a physician

immediately and be prepared to provide the

label from the chemical container.

AIR

WATER

EARTH

Wand

Cover

Filter

Nozzle

Calibrator

Bottle

Band width

1.6 ft

2.3 ft

3.3 ft

4.0 ft

5.0 ft

0.5m

0.7m

1.0m

1.2m

1.5m

Distance to walk

165 ft

120 ft

80 ft

70 ft

55 ft

50.0m

35.7m

25.0m

20.8m

16.7m

Band

Width

1. Hold the wand at

the working

height and spray

a test pattern to

measure the

application band

width.

2. Based on the band width,

identify from the table

below the walking distance

required to calibrate the sprayer.

Calibrating the Sprayer

Safety Precautions

Nozzle

Cap

Tip

Filter

Swirl

Core

Disc

Filter

Tip

The spraying angle is

changed by turning

the tip

Cap

Cap

Adjustable Cone

Nozzle

Cone Nozzle

Flat Fan Nozzle

Typical Nozzle Assemblies

(Requires optional flow calibrator bottle, P/N 646901)