6

This unit comes fully assembled with

the exception of the cutting attachment

shield and cutting attachment.

Before assembling, make sure you have

all the components required for a com-

plete unit and inspect unit and compo-

nents for any damage.

Engine and shaft assembly

Cutting attachment shield

Cutting attachment

Kit containing cutting attachment

shield bracket and hardware, this own-

er's/opertor's manual and tool kit for

routine maintenance. Tool kits vary by

model and may include a hex wrench

set, spark plug/screwdriver combina-

tion wrench and a spanner.

■

■

■

■

IMPORTANT!

The terms “left,” “left-hand,” and “LH”:

“right,” “right-hand,” and “RH”; “front”

and “rear” refer to directions as viewed

by the operator during normal operation

of this product.

Assembly

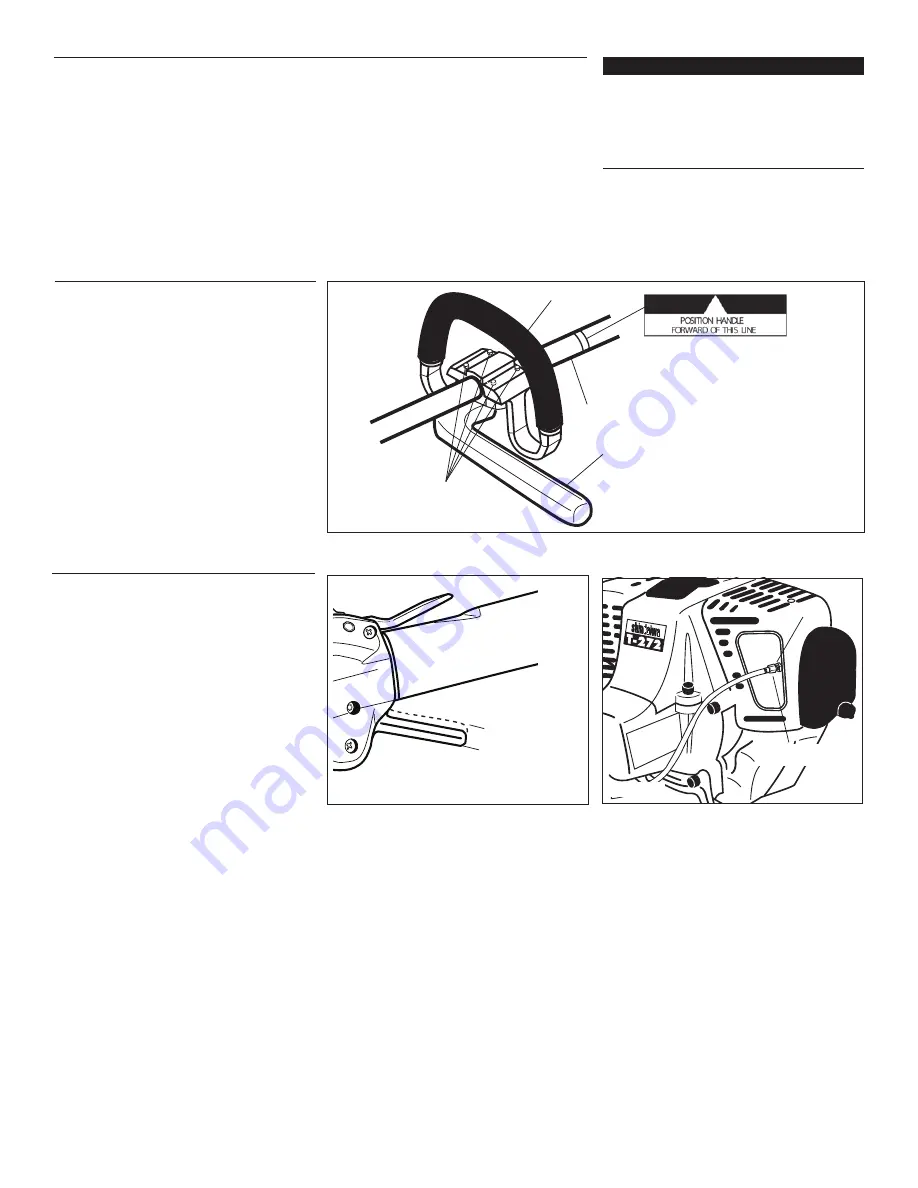

The handle is attached to the outer tube

on the T7/T7X. To adjust the handle:

Loosen the 4 socket-head capscrews

on the handle. See Figure 5.

Position the handle forward of the

Handle Positioning Label at the best

position for operator comfort (usually

about 10 inches ahead of the throttle

housing).

Secure the handle by alternately tight-

ening the four socket-head cap screws

in a diagonal or “criss-cross” fashion.

1.

.

3.

Outer Tube

Handle

Handle Positioning Label

4 Socket-head

Capscrews

Figure 5

Barrier Bar

T272X Shown

Adjusting Throttle Level Free Play T272/T272X

The throttle lever free play should be approxi-

mately 7 mm. See Figure 7. Make sure that

the throttle lever operates smoothly without

binding. If it becomes necessary to adjust

the lever free play, follow the procedures and

illustrations that follow.

Loosen the lock nut on the cable

adjuster. See Figure 6.

Turn the cable adjuster in or out as

required to obtain proper free play of

9/3 inch (7mm). See Figure 7.

Tighten the locknut.

1.

.

3.

Figure 6

Cable

Adjuster

Locknut

7 mm

Figure 7

Handle T272/T272X

Prior to Assembly