6

Assembly

This unit comes fully assembled. You

only need attach the accessory tool of

your choice to the powerhead. Your unit

includes:

Engine/outer tube assembly

Ŷ

Gearcase/cutter assembly

Ŷ

Prior To Assembly

This manual and tool kit for routine

Ŷ

maintenance.

Cutter blade cover

Ŷ

Carefully inspect all components for

damage.

IMPORTANT!

The terms “left”, “left-hand”, and “LH”;

“right”, “right-hand”, and “RH”; “front” and

“rear” refer to directions as viewed by the

operator during normal operation.

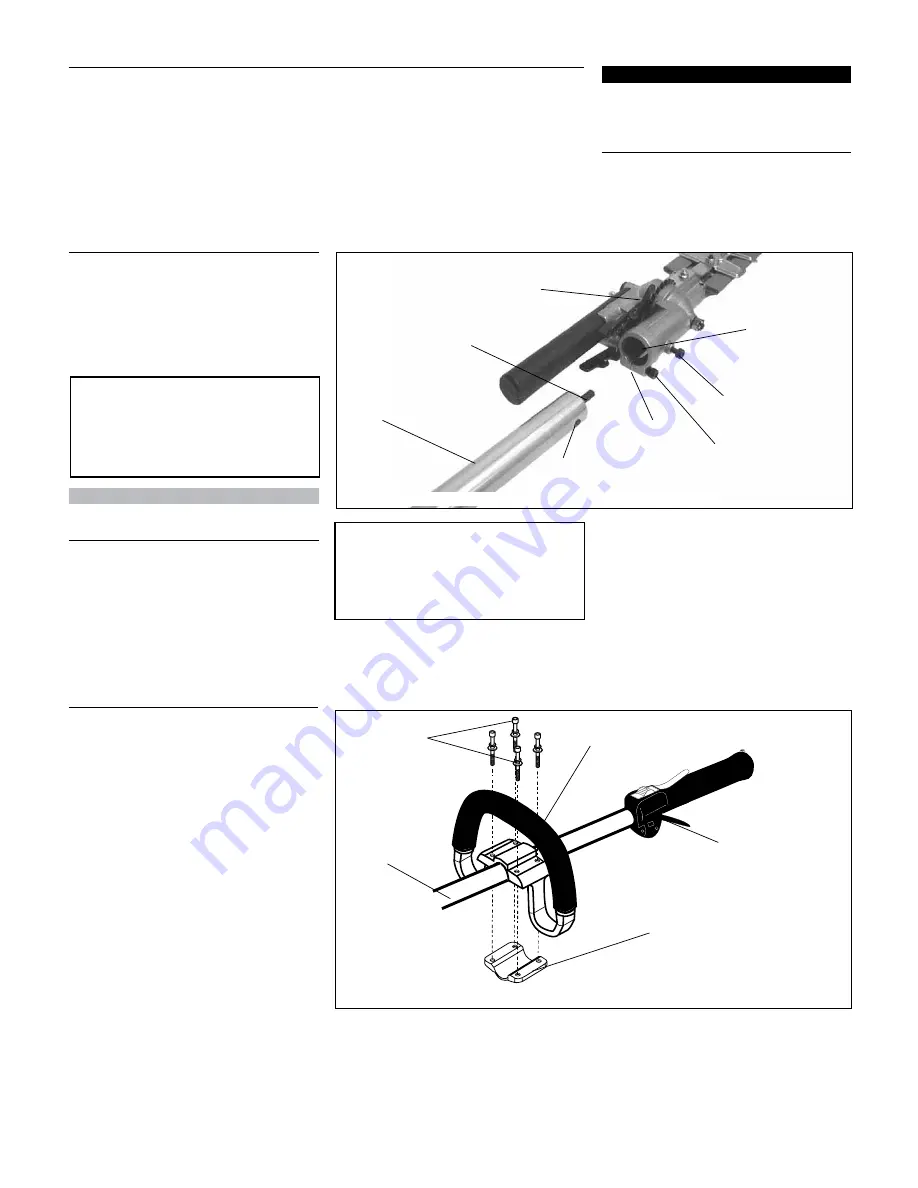

Index Screw

Gearcase/Cutter

Assembly

Mainshaft

Tube

Clamp

Outer Tube

Place the powerhead/outer tube assem-

1.

bly on a clean, flat surface, spark plug

facing up.

Use the 4mm hex wrench to loosen the

2.

tube clamp and index screw. Verify that

the D-shaped shim washer is positioned

as shown.

Connect the Powerhead/Outer Tube to the Gearcase

Clamp Screw

D-Washer

Index Hole

CAUTION!

Do not force the shaft tube into the

gearcase! Excessive force can dam-

age the shaft tube and mainshaft.

CAUTION!

Do not remove the D-shaped shim

washer! The shim washer prevents

damage from overtightening the

tube clamp screw.

Slide the outer tube into the tube clamp

3.

until the tube bottoms. If installation is

difficult, rotate the outer tube or main

shaft slightly until you feel the main-

shaft splines engage with the gearcase.

Position the outer tube so that the index

4.

hole on the outer tube is aligned with the

index screw on the gearcase tube clamp.

Using finger pressure only, thread the

5.

index screw into the index hole located

on the outer tube until it bottoms out.

Tighten the index screw and the clamp

6.

screw firmly.

NOTE:

It may be necessary to twist the outer tube

slightly for the index screw to be inserted fully.

Outer Tube

Socket-head

Capscrews

Handle

Mounting Bracket

Throttle Assembly

Position the handle on the outer tube as shown

Connect the outer tube to the gearcase

Handle

This unit comes with the handle installed.

It can be re-adjusted for operator comfort

in the following manner.

Loosen the four hex screws.

1.

Rotate/slide handle assembly to best

2.

position for operator comfort, usually

25 cm (10 in.) ahead of the throttle

assembly.

Tighten hex screws in a crisscross

3.

manner.

Summary of Contents for AHS2510

Page 22: ...22 NOTES NOTAs REMARQUES ...

Page 23: ...23 NOTES NOTAs REMARQUES ...

Page 46: ...SP_22 Español NOTES NOTAs REMARQUES ...

Page 47: ...SP_23 Español NOTES NOTAs REMARQUES ...

Page 70: ...Français FR_22 NOTES NOTAs REMARQUES ...