6

BP3511

BP3509

BP3504

BP3510

BP3508

BP3507

BP3506

BP3505

Assembly: Driveshaft/Powerhead

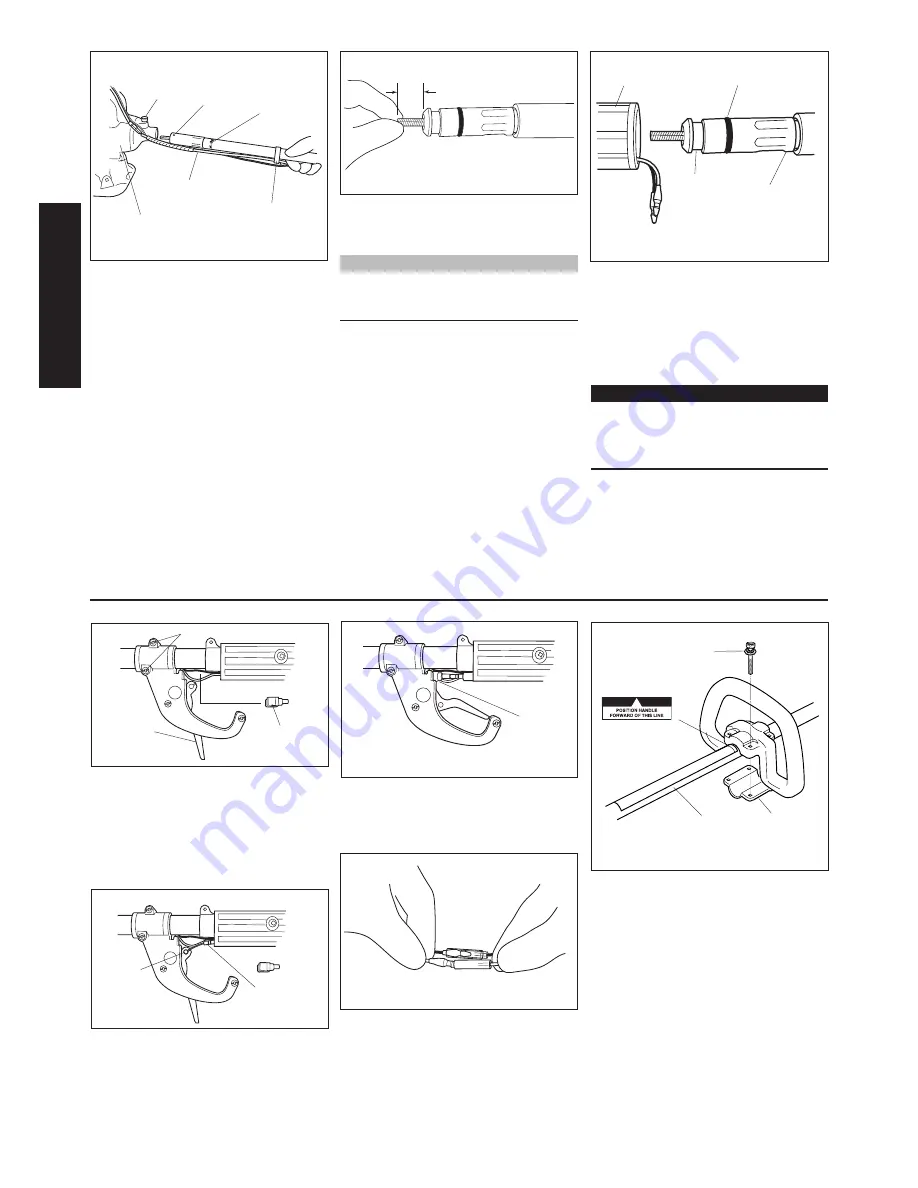

1. Place the powerhead on a flat surface.

2. Route the “engine side” of the flex

cable through the cable holder.

3. Remove the two protective covers

from the flex cable and insert the flex

cable housing marked “engine end”

into the powerhead with the locking

hole facing up. See Figure 4.

4. Lift up on the flex cable release knob

and slide flex cable housing all the

way in until it bottoms in the case and

the release knob locks into the lock-

ing hole in the flex cable housing. See

Figure 5.

BP35 Brushcutter

ASSEMBL

Y

Figure 4

5. From the opposite end, rotate and

push the drive cable to engage it into

the clutch drum. See Figure 5.

NOTE:

No more than 7/8” (22 mm) of the flex

cable should protrude from the flex cable

housing when properly installed.

Figure 5

6. Remove the Phillips head screw

from the rear hand grip and slide the

O-ring end of the flex cable housing

into the rear of the outer tube handle

until the groove on the housing lines

up with the hole for the Phillips head

screw. See Figure 6.

IMPORTANT!

It may be necessary to rotate the

output shaft of the gearcase to fully

engage the drive cable into the lower

tube assembly.

7. Install and tighten the Phillips head

screw firmly.

Figure 6

Release Knob Locking

Hole

“Engine Side”

Label

Throttle Cable

Cable Holder

7/8"

Powerhead

Groove

O-Ring

Rear Handle

Flex Cable

Housing

Throttle and Handle Assembly

Install the Handle

Cable

Guide

Outer Tube

Throttle Cable

Handle Position

Label

Figure 11

Throttle

Lever

Figure 8

Figure 7

Cable

End

Lower

Clamp

Figure 9

1. Use a Phillips head screwdriver to

remove the lower clamp retaining

screws from the handle. Separate the

clamp from the handle.

2. Position the handle on the outer tube

behind the handle positioning label.

Reassemble the lower clamp to the

handle in the reverse order of disas-

sembly. See Figure 11.

3. Firmly tighten the (4) handle retain-

ing screws. See Figure 11.

Install the Throttle Cable

1. Loosen the two screws securing the

throttle assembly and slide it forward

on the outer tube. See Figure 7.

2. Remove the cable guide to allow

the throttle trigger to swing out.

See Figure 7.

3. Slide the throttle cable through the

hand grip and insert the cable end

into the recess in the throttle trigger.

See Figure 8.

4. Install the cable guide and slide

the throttle assembly back into

place. Tighten the screws securely.

See Figure 9.

5. Connect the powerhead and stop

switch wire terminals.

Figure 10

Loosen screws

Cable

Guide

Clamp Retaining

Screw

Summary of Contents for BP35

Page 19: ...19 NOTES ...