12

Starting the Engine

(Continued)

7. Open the choke by moving the choke

lever down.

8. If the engine does not continue to

run, repeat the starting procedure as

previously described.

9. When the engine starts, clear excess

fuel from the combustion area by

revving the engine several times with

the throttle lever.

When the engine starts or fires–

Choke

Open

WARNING!

The cutting attachment will

rotate as the engine accelerates!

10. Operating the throttle will automatically

disengage the fast-idle setting.

3. If the spark plug electrodes and ceramic

insulator are fouled or soaked with

fuel, clean or replace the plug. For

spark plug specifications and gapping

procedure, refer to page 17.

4. Open the choke.

5. Hold the throttle control lever

depressed and crank the engine several

times to clear excess fuel from the

combustion chamber.

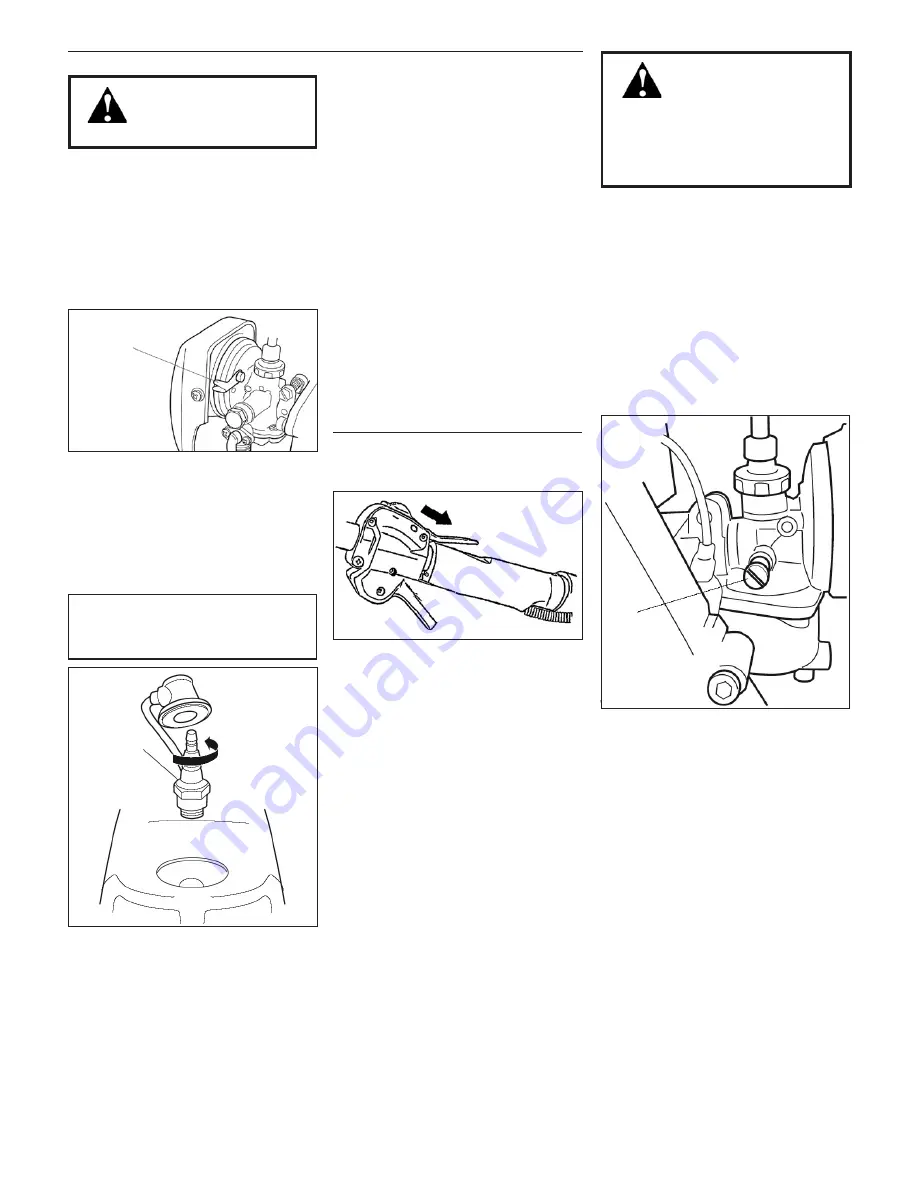

6. Reinstall the spark plug finger tight and

tighten it firmly with the spark plug

wrench provided in the tool kit. If a

torque wrench is available, torque the

spark plug to 16.7-18.6 Nm.

7. Repeat the “warm engine” starting

procedure.

8. If the engine fails to start, consult the

troubleshooting guide provided.

Starting a Flooded Engine

1. Slide the ignition switch button to the

STOP position.

2. Disconnect the spark plug wire, and

remove the spark plug.

CAUTION!

Incorrect spark plug installation may

cause serious engine damage!

Spark Plug

Turn

counterclockwise

to remove.

Stopping the Engine

Idle the engine briefly before stopping

(about 2 minutes), then slide the ON-OFF

switch to the "O" (for STOP) position.

Ignition OFF

Engine Idle Adjustment

The engine must return to idle speed

whenever the throttle lever is released.

Idle speed is adjustable, and must be set

low enough to permit the engine clutch to

disengage the cutting attachment when the

throttle is released.

1. Place the unit on the ground, then

start the engine and allow it to idle 2-3

minutes until warm.

2. If the attachment rotates when the

engine is at idle, reduce the idle speed

by turning the idle adjustment screw

counter-clockwise.

WARNING!

The cutting attachment

must NEVER rotate at engine idle! If

the idle speed cannot be adjusted by

the procedure described here, have

the unit inspected at an authorized

Shindaiwa dealer.

Idle

Adjusting

Screw

3. If a tachometer is available, the engine

idle speed should be final adjusted to

2,500 rpm (min

-1

).