14

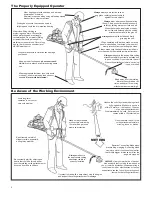

Using a Brushcutter Equipped

with a Blade

A blade-equipped brushcutter is a

professional tool that demands the utmost

attention. Observing the following

important guidelines will help ensure safe

and effective performance from your

brushcutter.

Operation

WARNING!

Your brushcutter is

equipped with a barrier-

type handlebar, shoulder harness,

and a cutting attachment debris

shield. These items must be

installed and adjusted according

to the instructions in this manual

before using the unit with a

blade or a trimmer head cutting

attachment.

A unit equipped with a blade can

throw or get entangled in loose

objects. Before operating, inspect

area thoroughly. Remove all

objects, such as rocks, broken

glass, nails, wire, or string. Note

location of large rocks, stumps,

and other fixed objects to avoid

hitting them.

Make sure children, bystanders,

and pets are at least outside

a 15 meter radius. If a child,

person, or pet comes into the 15

meter radius, stop the engine

immediately

Beware of the dangers of blade

thrust! Blade thrust can occur

when the top right cutting zone of

the blade strikes a fixed object.

Blade thrust can be violent

enough to cause the unit and/or

operator to be propelled in any

direction, and possibly loose

control of the unit. A violent blade

thrust posses an extreme risk to

anyone and anything nearby.

Do not overreach! Do not raise

the cutting attachment above

waist level. Assume a safe and

comfortable position before

starting, and maintain your

balance at all times.

STOP the machine immediately

if it suddenly begins to vibrate or

shake. Inspect it for loose, broken,

missing, or improperly installed

parts or attachments.

Barrier Type Front Handle

The barrier type front handle helps

prevent the operator from moving forward

or the cutting attachment from moving

rearward to prevent inadvertent bodily

contact with the blade. The front handle

must be installed in accordance with the

instruction provided in this manual. Always

keep the front handle securely in place on

the unit.

Shoulder Harness

The shoulder harness provided with the

unit affords additional protection against

blade thrust. Additionally, a shoulder

harness provides support and comfort to

help ensure safe and efficient operation.

Before operating the brushcutter, make

sure the harness is adjusted correctly

to the operator. The shoulder harness is

equipped with a quick release mechanism

to assure that the unit can be released

quickly from the operator in the event of

emergency.

WARNING!

When transporting, make sure

the engine is not running and

blade is covered with blade cover.

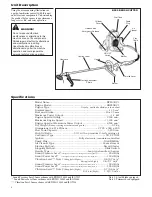

Avoid blade thrust by keeping the blade

in view during operation. Watch your cut

at all times. Cut ONLY small trees and/or

branches with the left side of the blade

between the 8 o’clock and 10 o’clock

positions as shown below. Avoid cutting

with any other part of the blade. When

cutting brush, sweep the blade from right

to left, always keeping the blade well in

front. It is recommended that the blade

be tilted down slightly to help keep debris

from accumulating on the edge of the

blade.

DO

NOT CUT

Ten

O'clock

Eight

O'clock

OK To Cut

Operate the machine at full throttle while

cutting. Best results are obtained by

releasing the throttle when swinging back

after completing a cut.

To prevent possible engine damage, do

not allow the brushcutter to run at high

speeds without a load.

Avoid operating the engine below the

recommended operational speed range.

Doing so can lead to rapid clutch wear.

In addition, slow-speed operation may

cause grass and debris to wrap around

the cutting attachment.

WARNING!

“BLADE THRUST” is a sudden

sideway or backward motion

of the machine. Such motion may

occur when the blade jams or catches

on an object such as a sapling tree or

tree stump. BE CONSTANTLY ALERT

FOR BLADE THRUST AND GUARD

AGAINST ITS EFFECTS.

WARNING!

Position the blade so cuts

are made between blade’s

8 o’clock and 10 o’clock positions

(as viewed from above). DO NOT cut

between the 11 o’clock and 5 o’clock

positions.

Engine Operating Speeds

WARNING!

When cutting small tress with a

blade, feed the blade slowly, never

strike or “slam” the spinning blade

against the tree trunk.

DO NOT use 2-tooth (lawn mower

type) cutting blades. Use only

Shindaiwa approved blades with

your Shindaiwa brushcutter.

Using a blade not authorized by

Shindaiwa may result in serious

injury.

Never repair a damaged blade

by welding, straightening, or by

modifying its shape. An altered

blade may break during operation,

resulting in serious personal injury.

Keep blades sharp and check

blade condition frequently. If

cutting performance changes

suddenly, stop the engine and

check the blade for cracks or other

damage. Replace the damaged

blade immediately!