20

DECLARATION

OF

CONFORMITY

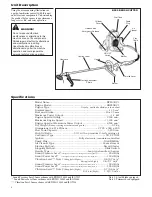

We hereby declare the Shindaiwa Engine Brushcutter,

Model RK45 (BP45/EC1).

meets the following respective requirements.

Council Directives:

Standard taken:

89/336/EEC as amended

EN 292 parts 1&2

98/37/EC as amended

ISO 14865

2000/14/EC as amended

ISO 14740

2004/26/EC as amended

CISPR 12

Measured sound power level: 109dB(A)

Guaranteed sound power level: 110dB(A)

Technical documentation is kept by:

K. Maeda DIV. Manager

Engineering Research and Development DIV.

Shindaiwa Kogyo Co., Ltd.

Head office : 6-2-11, Ozuka—Nishi, Asaminami—Ku,

Hiroshima, 731—3167, Japan

TEL: 81-82-849-2003, FAX: 81-82-849-2482

16th February, 2005

Shindaiwa Kogyo Co., Ltd.

T. Yoshitomi

DIV. Manager

Head office : 6-2-11, Ozuka—Nishi, Asaminami—Ku,

Quality Assurance DIV.

Hiroshima, 731—3167, Japan

TEL: 81-82-849-2206, FAX: 81-82-849-2481

Declaration of Conformity