8

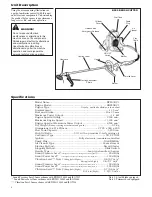

Throttle Cable Adjustment

WARNING!

NEVER operate this machine

without the cutting attachment shield.

Operating without the cutting attach-

ment shield may result in serious

injury.

Cutting Attachment Shield Assembly

1. Insert the cutting attachment shield

between the outer tube and the lower

clamp.

NOTE:

It may be necessary to loosen the lower

clamp bolt so that the shield will fit between

the tube and clamp.

2. Fit the upper clamp over the outer pipe

and install four bolts finger tight.

3. Tighten the lower clamp bolt and nut

securely.

4.

Securely tighten four upper clamp bolts in

a crisscross fashion.

Sub-Shield

(when trimmer head is in use)

1. Attach the shield extension to the

cutting attachment shield.

CAUTION!

Make sure the sub-guard is

completely hooked at the hook

receiver.

WARNING!

NEVER use this machine without

sub-shield when using a trimmer

head.

WARNING!

Carefully inspect the gearcase

and cutting attachment shield assembly

to make sure they are tightened securely

and do not wobble.

CAUTION!

Make sure the clamp screw and

retaining nut are securely tightened

before tightening the four socket head

cap screws.

CAUTION!

The line cutter is attached to the shield

extension and must be used when

operating with a trimmer head.

WARNING!

The line cutter is very sharp.

When handling, wear gloves to protect

your hands.

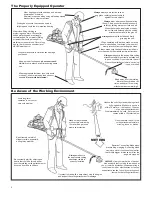

Assembly of the Handle

1. Put the 4 square nuts in the frame of the

barrier.

2. Fit the handle and barrier over the

outer tube and tighten the four bolts.

Square Nut

Barrier

Handle

Bolt

Barrier

3. Position the handle at the best position

for operator comfort.

4. Secure the handle by alternately

tightening the 4 bolts in a diagonal or

crisscross fashion.

Cutting Attachment Shield

Hook

Receiver

Hook

Sub-shield

1. Pulling the throttle trigger gently, make

sure the play is about 5 mm.

Play = 5 mm

2. If the play is too long or too short:

(a) Slide the cable cap toward the

muffler side until the adjusting nut

and the lock nut appear.

(b) Loosen the lock nut slightly.

(c) Turn the adjusting nut so that the

play becomes about 5 mm.

(d) Tighten the lock nut.

(e) Finally, slide the cable cap back.

Cable Cap

Adjusting

Nut

Lock Nut

Bolt

Upper Clamp

Spacer

Nut

Safety Guard