- 20 -

<Note>

Check that the surrounding area is safe before starting the engine.

When there are multiple workers who are working together, they must mutually signal

each other before starting the engine.

Do not use in an area with high temperature or humidity, or an area with a large

amount of dust.

Do not open any doors during operation. Operating with a door open can negatively

affect cooling effect, resulting in an equipment malfunction.

Use ear protection if the level of noise is high. Failure to do so could result in hearing

damage.

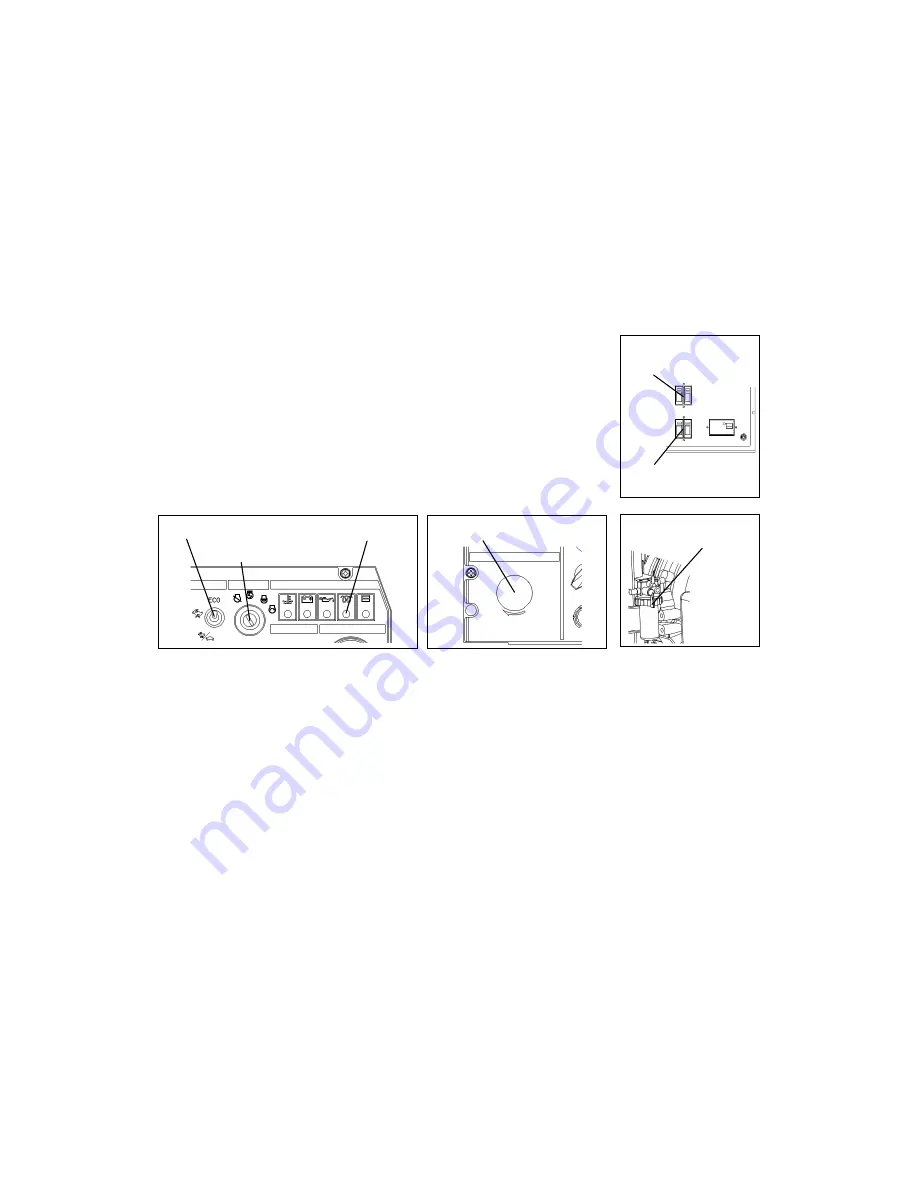

8-1. Starting the Engine

1)

Turn all breakers (1-P 110/115V and 1-P 230/240V) to "OFF".

2)

Turn the fuel lever (on the fuel strainer) to "OPEN".

3)

Set the idle control switch to "ECO" or "AUTO".

4)

Check that the emergency stop switch has been released.

5)

If the temperature is 5°C or less, turn the starter switch to the

"PREHEAT" position and wait until the preheat lamp turns off.

(approx. 5 seconds)

6)

Turn the starter switch to the "START" position to start the

starter motor, which then starts the engine.

7)

After the engine starts, remove your hand from the starter

switch.

8)

Allow the engine to warm up for approximately 5 minutes.

<Note>

Do not crank the starter motor for 15 seconds or more continuously.

If repeating starter switch operation, wait 30 seconds or more between operations.

After the engine starts, do not turn the starter switch to "START" during operation.

Restarting after Stopping due to Running Out of Fuel

The equipment includes an automatic air-bleeding device. You can easily restart the

engine according to the following procedures even if the engine stops due to running

out of fuel.

1)

Turn all breakers (1-P 110/115V and 1-P 230/240V) to "OFF".

2)

Turn the starter switch to the "STOP" position.

3)

Add fuel to the fuel tank.

4)

Set the idle control switch to "ECO" or "AUTO".

5)

Turn the starter switch to the "START" position and crank the starter motor for

approximately 10 seconds.

6)

After the engine starts, remove your hand from the starter switch.

7)

Wait for air to be completely bled from the fuel pipes and engine speed to stabilize

(approx. 1 minute).

*Engine speed is not stable until all air is bled from the fuel pipes.

<Note>

Do not switch the engine to high speed or apply any loads to it until all the air has

been bled from the fuel pipes (until speed is stable). Doing so can cause a

malfunction.

Fuel Lever

(on fuel strainer)

1-P

230/240V Breaker

1-P

110/115V Breaker

Emergency Stop Switch

Preheat Lamp

Starter Switch

Idle Control Switch

Summary of Contents for DGW400DMK

Page 2: ......

Page 41: ... 38 15 Engine Wiring Diagram ...

Page 42: ... 39 16 Generator Wiring Diagram P 1 2 ...

Page 43: ... 40 P 2 2 ...

Page 44: ... 41 MEMO ...

Page 45: ... 42 MEMO ...

Page 46: ... 43 MEMO ...

Page 47: ... 44 ...

Page 48: ... 45 2015 ...