7

Assembling the Blower

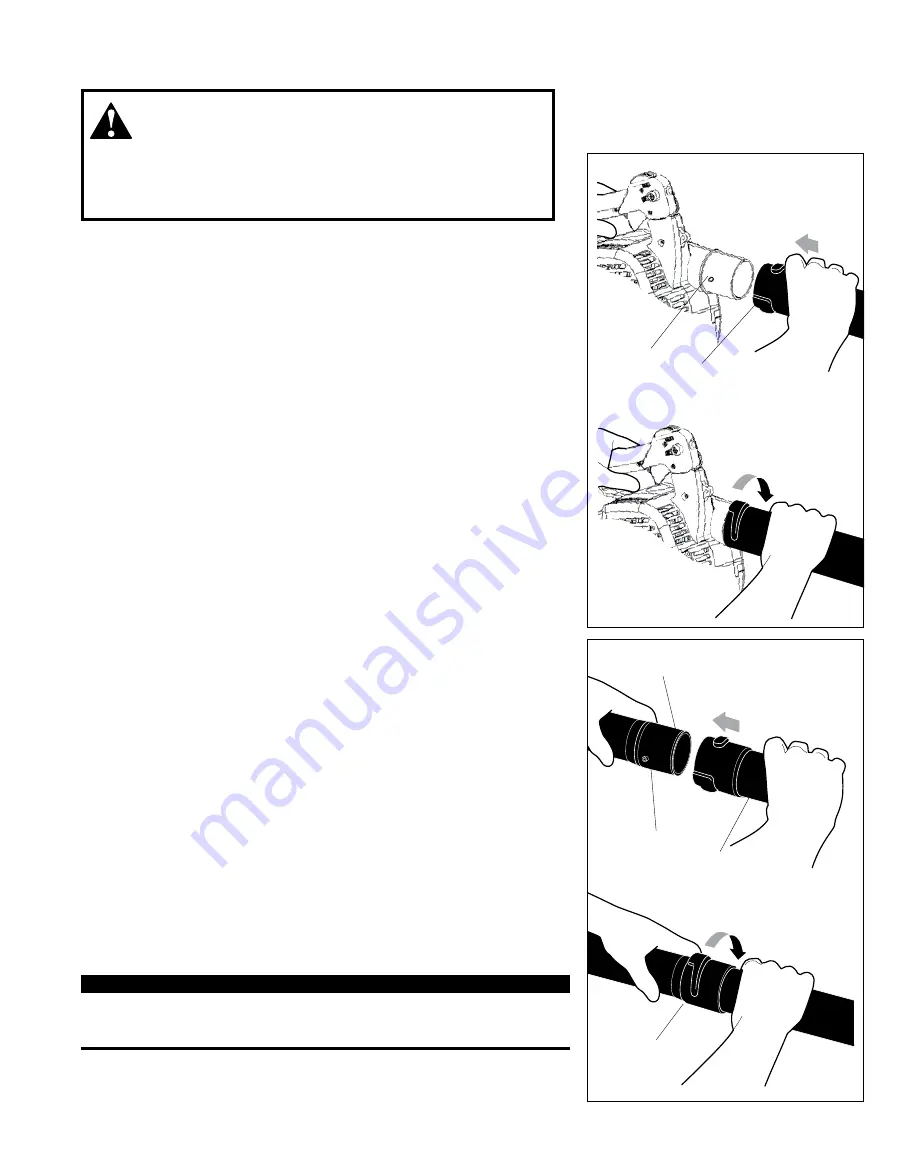

Place the blower upright on the ground or on a sturdy work surface.

1. Grasp the blower tube as shown, and push the tube over the blower dis-

charge port and locking pins.

2. Lock the blower tube to the blower discharge port by rotating the tube as

shown.

Blower

Tube

Locking Pin

Push the blower tube

over the discharge port

and locking pin

Rotate clockwise to lock

Nozzle

Locking Pin

Blower Tube

Push the nozzle

over the blower

tube and locking

pin

Rotate clockwise to lock

1

3

2

4

3. Grasp the nozzle with the mark “THIS SIDE UP” positioned as shown,

and then push the nozzle over the straight tube and locking pins.

4. Lock the nozzle to the straight tube by rotating the nozzle as shown.

Danger from

rotating impeller!

Stop the engine before installing or removing the blower tubes!

Never perform any maintenance or assembly procedures on this unit

while the engine is running!

WARNING!

IMPORTANT!

Blower tube installation affects both blower balance and performance!

The tube and nozzle are correctly installed when the mark “THIS SIDE

UP” is visible to the operator during normal operation.

Mark

“THIS SIDE UP”

must face up