11

23046

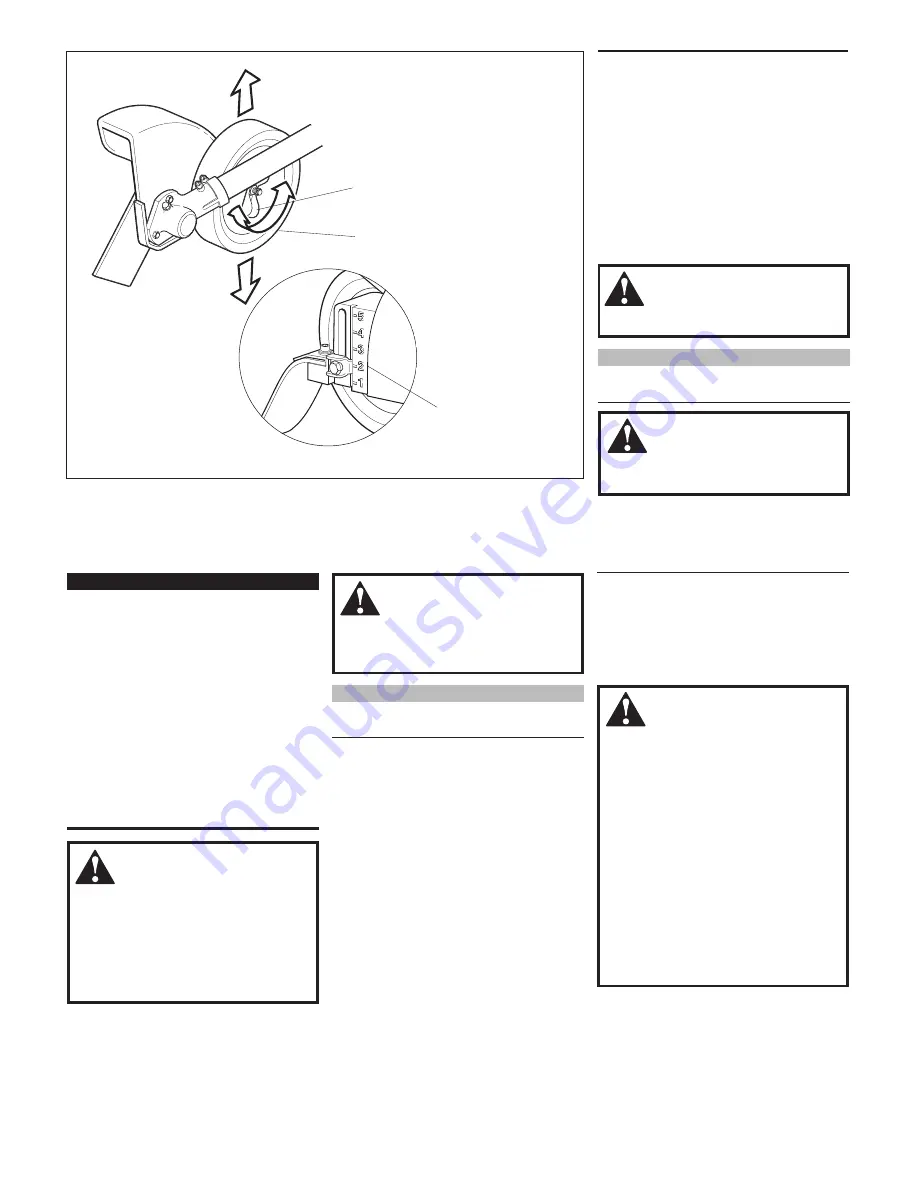

The edger’s depth of cut is controlled by a

combination of operator height, blade wear,

and the positioning of the edger’s guide

wheel.

To Adjust Blade Height:

1. Loosen the guide wheel adjusting knob.

2. Raise or lower the guide wheel to the

desired setting (see the inset).

3. Tighten the guide wheel adjusting knob

firmly.

WARNING!

Never adjust the guide wheel

while the engine is running.

NOTE:

Guide wheel adjustment is also required to

compensate for blade wear.

WARNING!

Use only Shindaiwa replacement

blades.

Adjusting the Blade Cutting Depth.

Guide Wheel

Adjusting knob

The numbers are for reference

only; they do NOT refer to depth

in inches

Figure 22

Guide Wheel

Using a Hand-Held Edger (Continued)

General Maintenance

IMPORTANT!

MAINTENANCE, REPLACEMENT OR

REPAIR OF EMISSION CONTROL DEVICES

AND SYSTEMS MAY BE PERFORMED

BY ANY REPAIR ESTABLISHMENT OR

INDIVIDUAL; HOWEVER, WARRANTY

REPAIRS MUST BE PERFORMED BY

A DEALER OR SERVICE CENTER

AUTHORIZED BY SHINDAIWA KOGYO

CO., LTD. THE USE OF PARTS THAT ARE

NOT EQUIVALENT IN PERFORMANCE

AND DURABILITY TO AUTHORIZED

PARTS MAY IMPAIR THE EFFECTIVENESS

OF THE EMISSION CONTROL SYSTEM

AND MAY HAVE A BEARING ON THE

OUTCOME OF A WARRANTY CLAIM.

WARNING!

Before performing any maintenance,

repair or cleaning work on the unit,

make sure the engine and cutting

attachment are completely stopped.

Disconnect the spark plug wire before

performing service or maintenance

work.

WARNING!

Non-standard parts may not operate

properly with your unit and may cause

damage and lead to personal injury.

NOTE:

Using non-standard replacement parts could

invalidate your Shindaiwa warranty.

Muffler

This unit must never be operated with a

faulty or missing spark arrester or muf-

fler. Make sure the muffler is well secured

and in good condition. A worn or damaged

muffler is a fire hazard and may also cause

hearing loss.

Spark Plug

Keep the spark plug and wire connections

tight and clean.

Fasteners

Make sure nuts, bolts, and screws (except

carburetor adjusting screws) are tight.

Blades

Check blade condition frequently. If a

blade’s performance changes suddenly,

stop the engine and check the blade for

cracks or other damage. Replace a dam-

aged blade IMMEDIATELY!

WARNING!

Never repair a damaged blade by

welding, straightening, or by modify-

ing its shape. An altered blade may

break during operation, resulting in

serious personal injury.

The LE230 Edger is designed for

use with a single, bar-type blade

only.

Blades are

not

interchangeable

between Shindaiwa edgers and

trimmer/brushcutter models.

Operating any unit with a blade or

attachment not approved for that

unit can be hazardous and may

cause serious injury.

Summary of Contents for LE230

Page 18: ...18 NOTES...

Page 19: ...19 NOTES...