LE262

TROUBLESHOOTING

X7502341501

37

© 03/2019 ECHO Inc.

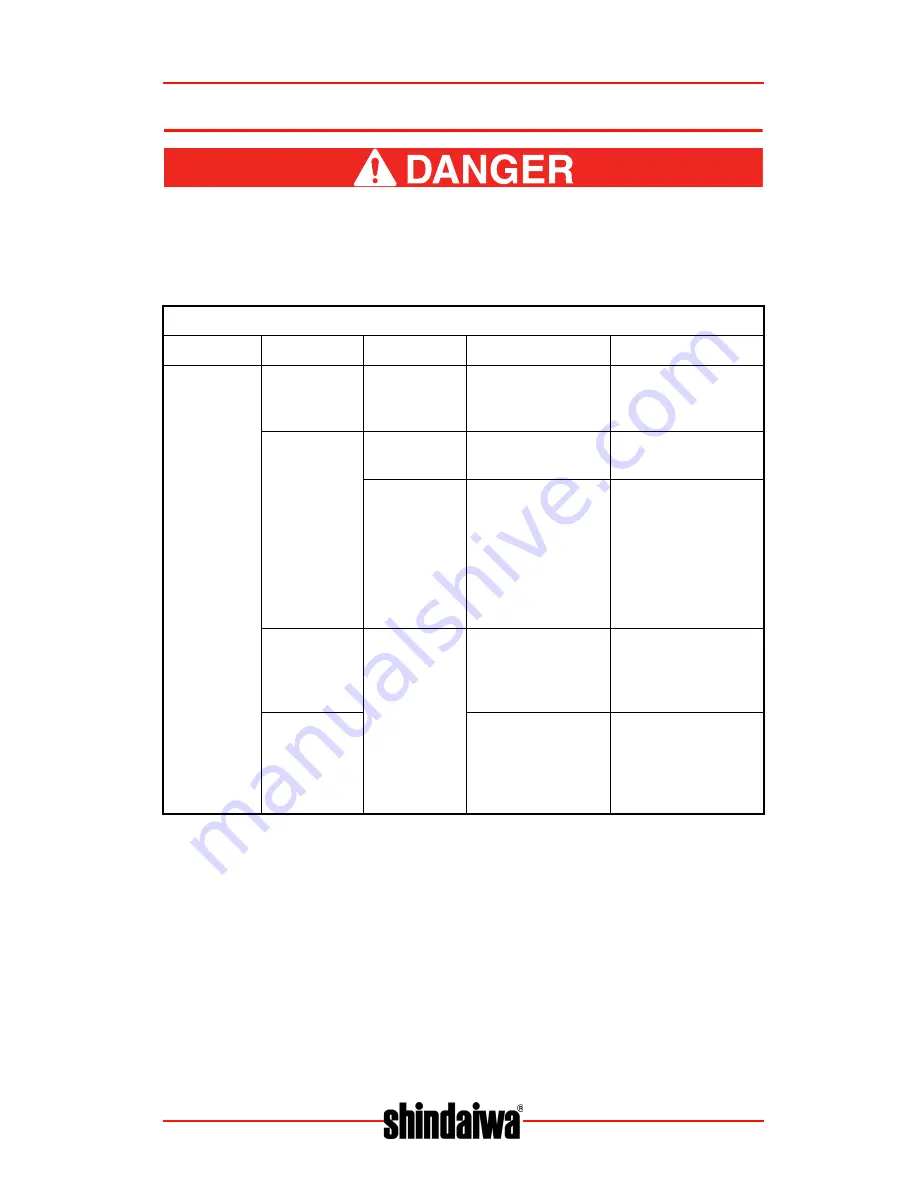

TROUBLESHOOTING

Fuel vapors are extremely flammable and may cause fire and/or

explosion. Never test for ignition spark by grounding spark plug

near cylinder plug hole, otherwise serious personal injury may

result.

ENGINE PROBLEM TROUBLESHOOTING CHART

Problem

Check

Status

Cause

Remedy

Engine

starts hard

or

Engine

does not

start

Fuel at

carburetor

No fuel at

carburetor

Fuel strainer or

fuel line

obstructed

Clean or replace

See your dealer

Fuel at

cylinder

No fuel at

cylinder

Carburetor

See your dealer

Muffler wet

with fuel

Fuel mixture too

rich

OPEN choke

Clean or replace

air filter

Adjust carburetor

See your dealer

Spark at

end of plug

wire

No spark

Stop switch OFF

- Electrical

problem -

Interlock switch

Turn switch to ON

See your dealer

Spark at

plug

Incorrect gap -

Covered with

carbon - Fouled

with fuel - Plug

defective

Adjust to 0.65mm

(0.026 in.)

Clean or replace

plug