36(40)

7. Troubleshooting

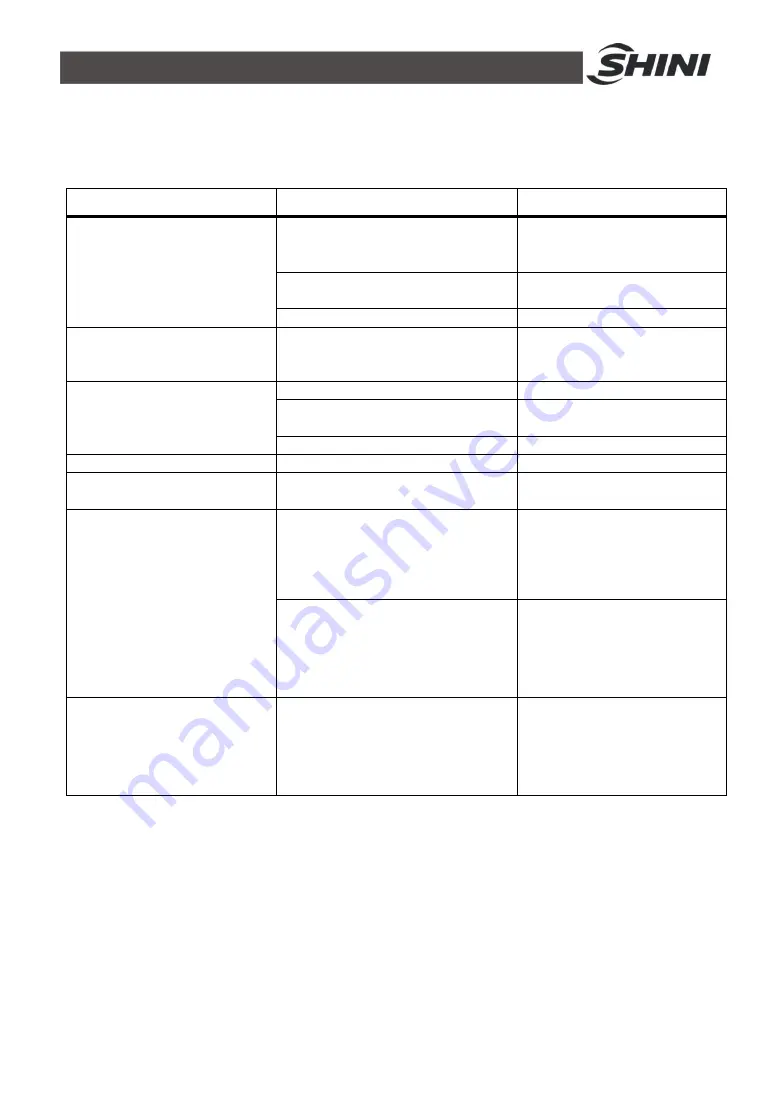

7.1 Troubleshooting for SAL-330/360 Series

Failures

Possible Causes

Solutions

Motor does not work long after

material discharged

Did not turn on main power or

control switch or poor connection of the

switches

Turn on main power switch and

control switch and make sure

they keep good contact.

Poor connection of microswitch or

photoelectrical sensor

Adjust or replace

Signal wire broken

Refix signal wire

Motor keep on working

after the hopper is full

filled

Contactor malfunctions

Repair or replace contactor

Can not full-load the

material for several times or

alarm indicating

material shortage

Material is used up

Add material to storage bin

Leakage in conveying hose

Lock up or replace conveying

hose

Filter screen is blocked

Clear up filter screen

Motor does not work

Short of phase or motor failures

Repair or replace

Fuse melt after startup of the

machine

Short circuit or motor failures

Check electrical circuit

The alarm indicating

motor overload

Filter screen is blocked

After cleaning of filter

screen,press Reset on the

overload relay.

Phase shortage

After fixed the circuit, press Reset on

the overload relay.

Poor material liquidityin the pipe Over or lack of air quantity

Adjust air inlet location of the

suction box.

Avoid small bending of the

elbow.

Summary of Contents for SAL-330

Page 1: ...SAL 330 360 Self contained Hopper Loader Date Jan 2016 Version Ver B ...

Page 2: ......

Page 6: ...6 40 ...

Page 21: ...21 40 4 Electrical Circuit Diagram 4 1 Electrical Diagram Picture 4 1 Electrical diagram ...

Page 31: ...31 40 6 2 Function Setup 6 2 1 Setup ...

Page 33: ...33 40 ...

Page 34: ...34 40 ...