9(63)

All service work should be carried out by a person with technical training or

corresponding professional experience. The manual contains instructions for both

handling and servicing. Chapter 6, which contains service instructions intended for

service engineers. Other chapters contain instructions for the daily operator.

Any modifications of the machine must be approved by SHINI in order to avoid

personal injury and damage to machine. We shall not be liable for any damage

caused by unauthorized change of the machine.

Our company provides excellent after-sales service. Should you have any problem

during using the machine, please contact the company or the local vendor.

Headquarter and Taipei factory

:

Tel: (886) 2 2680 9119

Shini Plastics Technologies (Dongguan), Inc

:

Tel: (86) 769 8111 6600

Shini Plastics Technologies India Pvt.Ltd.

:

Tel: (91) 250 3021 166

Summary of Contents for SDL-U Series

Page 1: ...SDL U HD Series Heatless Dehumidifying Compact Dryer Date Nov 2014 Version Ver B English...

Page 2: ......

Page 11: ...11 63 1 3 2 Outline Drawing Picture 1 1 Outline Drawing...

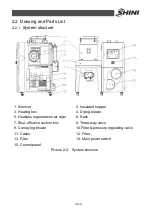

Page 17: ...17 63 Picture 2 1 Working Principle...

Page 27: ...27 63 2 3 2 Main Circuit SDL 20U 450U HD Picture 2 6 Main Circuit SDL 20U 450U HD...

Page 28: ...28 63 2 3 3 Control Circuit SDL 20U 450U HD Picture 2 7 Control Circuit 1 SDL 20U 450U HD...

Page 29: ...29 63 Picture 2 8 Control Circuit 2 SDL 20U 450U HD...

Page 38: ...38 63 Picture 2 10 Main electrical circuit SDL 600U 1200U HD...

Page 39: ...39 63 2 3 7 Control circuit SDL 600U 1200U HD Picture 2 11 Control circuit 1 SDL 600U 1200U HD...

Page 40: ...40 63 Picture 2 12 Control circuit 1 SDL 600U 1200U HD...