26(49)

3.3 SS-S1 Features

1. The guide rod used alloy material, small friction and wearable.

2. The gripper comes with sensor and rotate wrist device.

3. Shock absorber and proximity switch made rotate cylinder moves smoothly.

4. Shock absorber and magnetic switch made crosswise cylinder smoothly moves forward or

backward.

5. Fast mold changing design provides simple method for changing molds. The base is

rotatable for 90

by releasing the handle.

℃

6. Easy to change robot reversing: loosen bolt and push cylinder to the other side.

7. Branded pneumatic accessories provide extensive use life. Removable electric circuit

stands allows easy maintenance.

8. Use movable mounting frame for electrical accessories.

9. Dialogic hand controller provides English, Japanese, Traditional Chinese and Simplified

Chinese. Other languages are applicable. There are 8 standard programs and memory

for up to 80 customized programs with self fault detection.

10. Extra sets of I/O pins are available for other applications.

11. Designed to Euromap12, Euromap67 and SPI to provide plug and use.

3.4 Functions

3.4.1 Function Description

Designed for rapid and precise removal of sprue and runner from injection molding, and

place them into granulator for recycling. Simple product removal is applicable with optional

vacuum generator and EOAT. Suitable for injection molding machine under 250T clamp

force.

In order to ensure the robot works smoothly, there are shock absorbers and magnetic sensor

switches on the main parts of the robot, and having pneumatic cut off protection device on

arms.

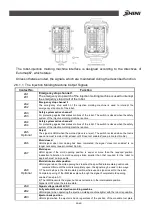

3.4.2 Shock Absorber

Picture 3-1: Shock Absorber on Crosswise