28(147)

Stroke(mm)

Sub-arm

200

Main Arm

1500

1500

Vertical Stroke(mm)

Sub-arm

1550

Max Load(kg)

6

6

Min Pick-out Time(sec)

3

3

Min Cycle Time(sec)

8.5

8.5

Air Pressure Range(bar)

4-6

4-6

Max Air Consumption(N/cycle)

29

45

Net Weight(kg)

460

490

A

2970

2970

B

1750

1750

C

1590

1590

D(max)

1500

1500

E(max)

1550

F(max)

2200

2200

G(max)

120

H(max)

180

Dimensions

(mm)

I(max)

1150

1150

Note: 1.

“

M

”

stands for middle mold detector, suit for 3-plate mold.

“

EM12

”

stands for EUROMAP12 communication interface.

“

EM67

”

stands for EUROMAP 67 communication interface.

“

N

”

stands for non-operation side,operation side without

“

N

”

2. Power supply: 1

Ф

,

200~240V

,

50/60Hz.

3.

”

*

”

max air consumption for suction device 60NI/min.

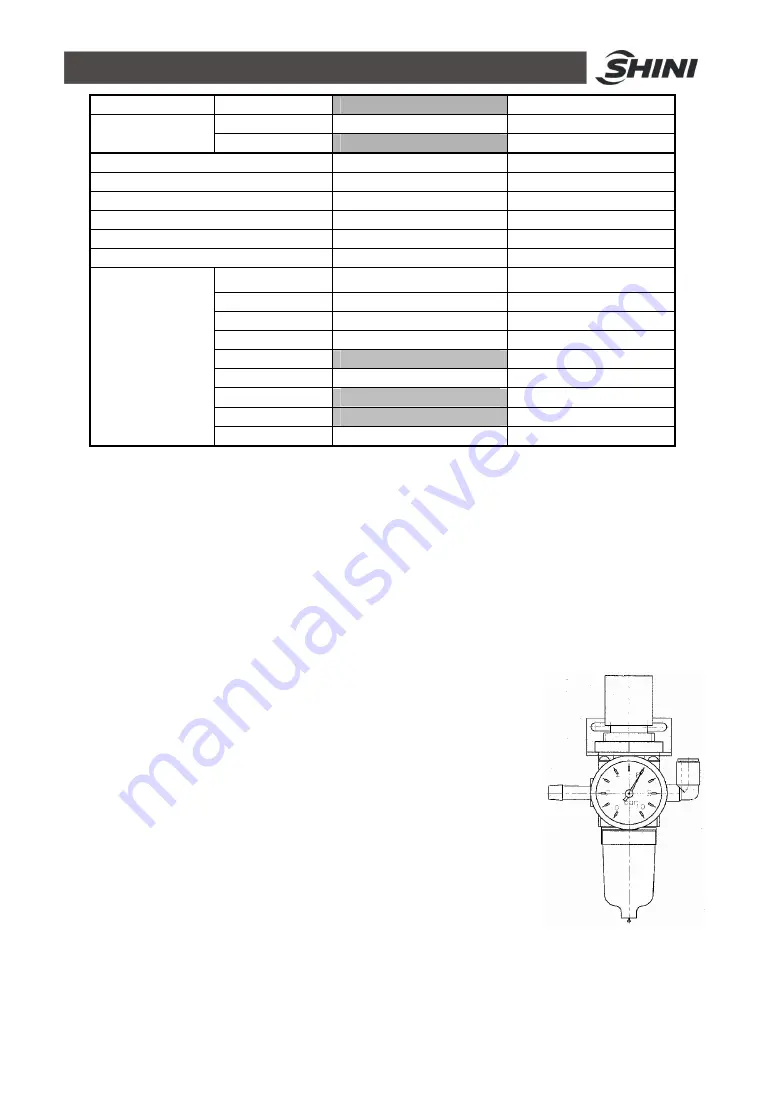

2.2.3 Pneumatic Source Requirement

Compressed air is connected by 3/8-

Ф

12 trachea.

Filter pressure valve with a clear scale line, convenient

adjustment. Bring adjustment knob upward and with a

clockwise rotation, pressure increases; counterclockwise

rotation, air pressure decreases, the pressure range

between 0 to10bar. After adjustment, Please press the

adjustment knob to lock pressure.

Required supply pressure

:

4bar-6bar

When the pressure is equal or drop below than 4 bar, the

robot will stop working and alarm. When the pressure up to

6bar, It will affect the service life of pneumatic components.

Compressed air consumption depends on the robot accessories.

Summary of Contents for ST1-1100-1800

Page 1: ...ST1 Single Axis Servo Driven Robot User Manual Date May 2016 Version V1 4 English ...

Page 2: ......

Page 46: ...46 147 Picture 2 3 X025 sensor Picture 2 4 X 025 lights up ...

Page 76: ...76 147 7 Assembly Diagram 7 1 Traverse Unit ST1 and ST1 T Picture 7 1 ...

Page 88: ...88 147 7 2 Vertical Unit ST1 Picture 7 2 ...

Page 93: ...93 147 7 3 Main arm unit ST1 Picture 7 3 ...

Page 98: ...98 147 7 4 Sub Arm unit ST1 Picture 7 4 ...

Page 101: ...101 147 7 5 Main Arm ST1 T Picture 7 5 ...

Page 104: ...104 147 7 6 Sub arm ST1 T Telescopic Arm Picture 7 6 ...

Page 107: ...107 147 7 7 Vertical ST1 T Telescopic Arm Picture 7 7 ...

Page 110: ...110 147 7 8 Traverse unit ST1 T Middle Telescopic Arm Picture 7 8 ...

Page 115: ...115 147 7 9 Main Arm ST1 T Middle Telescopic Arm Picture 7 9 ...

Page 120: ...120 147 7 10 Sub arm ST1 T Middle Telescopic Arm Picture 7 10 ...

Page 125: ...125 147 7 11 Crosswise Unit ST1 T Middle Telescopic Arm Picture 7 11 ...

Page 129: ...129 147 8 Electric Control Chart 8 1 The Power Input Wiring Diagram Picture 8 1 ...

Page 130: ...130 147 8 2 Main Control Panel and I O Wiring Diagram Picture 8 2 ...

Page 131: ...131 147 8 3 Panasonic Servo Motor Wiring Diagram 1 Picture 8 3 ...

Page 132: ...132 147 8 4 Panasonic Servo Motor Wiring Diagram and Spare Wiring Diagram M1 3 Picture 8 4 ...

Page 133: ...133 147 8 5 YASKAWA Servo Motor Wiring Diagram 1 Picture 8 5 ...

Page 134: ...134 147 8 6 YASKAWA Servo Motor Wiring Diagram and Spare Wiring Diagram M1 3 Picture 8 6 ...

Page 135: ...135 147 8 7 Z axis Wiring Diagram Picture 8 7 ...

Page 136: ...136 147 8 8 Main Arm Wiring Diagram 1 Picture 8 8 ...

Page 137: ...137 147 8 9 Main Arm Wiring Diagram 2 Picture 8 9 ...

Page 138: ...138 147 8 10 Sub Arm Wiring Diagram Picture 8 10 ...

Page 139: ...139 147 8 11 EM67 Signal Input Wiring Diagram Picture 8 11 ...

Page 140: ...140 147 8 12 EM67 Signal Output Wiring Diagram Picture 8 12 ...

Page 141: ...141 147 8 13 Main Control Board Component Layout Picture 8 13 ...

Page 142: ...142 147 8 14 I O U2 Board Component Layout 0 Picture 8 14 ...

Page 144: ...144 147 8 16 Main Arm U4 Layout Picture 8 16 ...

Page 145: ...145 147 8 17 Sub arm U5 Component Layout Picture 8 17 ...

Page 147: ...147 147 ...