29(142)

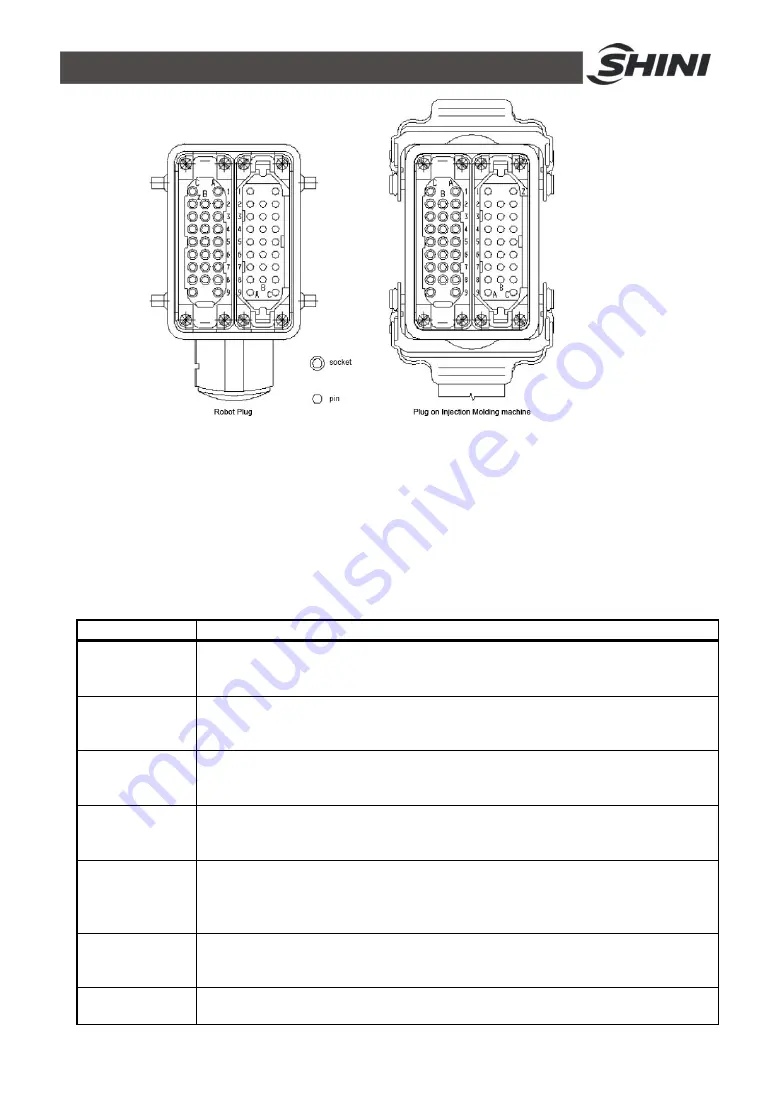

The robot-injection molding machine interface is designed according to the

directives of Euromap67, which states:

Unless otherwise noted, the signals, which are maintained during the described

function.

2.5.1.1

The Injection Molding Machine Output Signals

Contact No.

Function

ZA1

ZC1

Emergency stop channel 1

The emergency stop switch of the injection molding machine is used to

interrupt the emergency stop circuit of the robot.

ZA2

ZC2

Emergency stop channel 2

The emergency stop switch of the injection molding machine is used to interrupt the

emergency stop circuit of the robot.

ZA3

ZC3

Safety system active channel 1

For protecting against hazardous motions of the robot. The switch is closed when the

safety system of the injection molding machine is active.

ZA4

ZC4

Safety system active channel 2

For protecting against hazardous motions of the robot. The switch is closed when the

safety system of the injection molding machine is active.

ZA5

Optional

Reject

The signal is HIGH when the molded piece is a reject. The switch is closed when the

tool is open and must remain HIGH at least until

“

close tool enabled

”

(see pin contact

No.A6).

ZA6

Mold closed

HIGH signal when tool closing has been completed, the signal

“

close tool enabled

”

is

no longer necessary (see pin contact No.A6).

ZA7

Mold open

HIGH signal if the mold opening position is equal or more than the required position.

Summary of Contents for ST1-S

Page 1: ...ST1 S User Manual Date May 2016 Vision V1 0 English ...

Page 2: ......

Page 10: ...10 142 ...

Page 94: ...94 142 7 Assembly Diagram 7 1 Traverse Unit ST1 S and ST1 T S Picture 7 1 ...

Page 99: ...99 142 7 2 Vertical Unit ST1 S Picture 7 2 ...

Page 102: ...102 142 7 3 Main Arm Unit ST1 S Picture 7 3 ...

Page 105: ...105 142 7 4 Sub arm Unit ST1 S Picture 7 4 ...

Page 108: ...108 142 7 5 Main Arm ST1 T S Picture 7 5 ...

Page 110: ...110 142 7 6 Sub arm ST1 T S Picture 7 6 ...

Page 113: ...113 142 7 7 Vertical ST1 T S Picture 7 7 ...

Page 115: ...115 142 7 8 Traverse Unit ST1 T S Middle Telescopic Arm Picture 7 8 ...

Page 119: ...119 142 7 9 Main Arm ST1 T S Middel Telescopic Arm Picture 7 9 ...

Page 123: ...123 142 7 10 Sub arm ST1 T S Middel Telescopic Arm Picture 7 10 ...

Page 127: ...127 142 7 11 Crosswise Unit ST1 T S Middle Telescopic Arm Picture 7 11 ...

Page 131: ...131 142 8 1 2 The Panasonic Servo Motor and Servo Driver Wiring Diagram Picture 8 2 ...

Page 132: ...132 142 8 1 3 The Panasonic Servo Motor and I O Board Wiring Diagram Picture 8 3 ...

Page 133: ...133 142 8 1 4 The Delta Servo Motor and Servo Driver Wiring Diagram Picture 8 4 ...

Page 134: ...134 142 8 1 5 The Delta Servo Motor and I O Board Wiring Diagram Picture 8 5 ...

Page 135: ...135 142 8 1 6 The Cuinsico Servo Motor and Servo Driver Wiring Diagram Picture 8 6 ...

Page 136: ...136 142 8 1 7 The Cuinsico Servo Motor and I O Board Wiring Diagram Picture 8 7 ...

Page 137: ...137 142 8 1 8 Z axis I O Board Wiring Diagram Picture 8 8 ...

Page 138: ...138 142 8 1 9 Main Arm Wiring Diagram Picture 8 9 ...

Page 139: ...139 142 8 1 10 Sub arm Wiring Diagram Picture 8 10 ...

Page 140: ...140 142 8 1 11 Main Arm Output Wirng Diagram Picture 8 11 ...

Page 141: ...141 142 8 1 12 Signals Input Wiring Diagram Picture 8 12 ...

Page 142: ...142 142 8 1 13 Signals Output Wiring Diagram Picture 8 13 ...