Import printer profile

Operation- Open File

Operation- Layout

Operation- Support

Operation- Slice

Operation- Send print job

Update software and

material profile

Function

Remote Assistance

Accuracy Calibration

Workflow

(Optional) Clean Resin Tank

Resin tank setting

Choose printing file

Local Printing

Flash Drive Printing

Printing Status

Remove Model

Post Processing

1.1

1

1.2

1.3

1.4

1.5

2

2.1

2.2

2.3

3.1

3.1.1

3

3.1.2

3.1.3

3.2

4

4.1

4.2

4.3

5

5.1

5.2

5.2.1

5.2.2

5.3

5.3.1

5.3.2

5.4

5.4.1

5.4.2

Clean Model

Cleaning

Clean Build Platform

Model Post Cure

Remove Support

CONTENT

5.4.3

5.4.4

5.4.5

5.4.6

5.4.7

5.4.8

5.4.9

5.4.10

5.4.11

5.4.12

6

6.1

6.3

6.2

6.4

6.4.1

6.4.2

6.5

7.1

Material Contact

Safety

Ultraviolet Light

Ethanol

Sharp Tools

Electromagnetic Interference

Operation Environment

Site Requirements

PC Recommended Configuration

for AccuWare

Material Storage

AccuFab L4D

Overview

Product Overview

Technical Parameters

Accessories

Fab Cure

Printer Setup

Unpacking

Install the Printer

Add Material

Fabware

Software operation

Connecting to Network

LAN Network

Wireless network

Fabware Update

Online Update

Offline update

Accuware

Installation

Import printer profile

7

7.2

.

1

7.2

7.2

.

2

7.3

7.4

1

2

3

4

CONTENT

1

1

Safety

1

1.1

Material Contact

1

1.2

Ultraviolet Light

1

1.3

Ethanol

1

1.4

Sharp Tools

1

1.5

Electromagnetic Interference

4

3

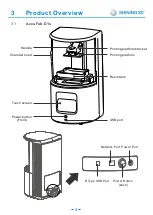

Product Overview

4

3.1

AccuFab-D1s

3.2

Accessories

5

6

4

Printer Setup

6

4.1

Unpacking

7

4.2

Install the Printer

8

4.3

Add Material

7.1

19

Remove Model

7.2

20

Cleaning

7.2

.

2

20

Clean Build Platform

7.2

.

1

20

Clean Model

7.3

21

Model Post Cure

7.4

21

Remove Support

7

Post Processing

19

6.1

13

Workflow

6.5

16

Choose Printing File

6.2

13

Resin Tank setting

6.4

15

Clean Resin Tank(Optional)

6.5.1

16

Local Printing

6.6

18

Printing Status

6.5.2

17

Flash Drive Printing

6

13

6.3

Platform level (Optional)

14

2

2

Operation Environment

2

2.1

Site Requirements

2

2.2

Material Storage

3

2.3

Others

5

9

FabWare

5.1

Connecting to Network

10

5.1.1

LAN Network

10

5.1.2

Wireless Network

10

5.2

FabWare Update

11

5.2.1

Online Update

11

5.2.2

Offline Update

11

Product Activation(Optional)

5 3

.

12