AccuFab-L4D & L4K_User Manual_V3.2.20_June 2021

37

6.

Product Care and Maintenance

Maintenance

Content

Maintenance

Requirements

Maintenance

Cycle

Note

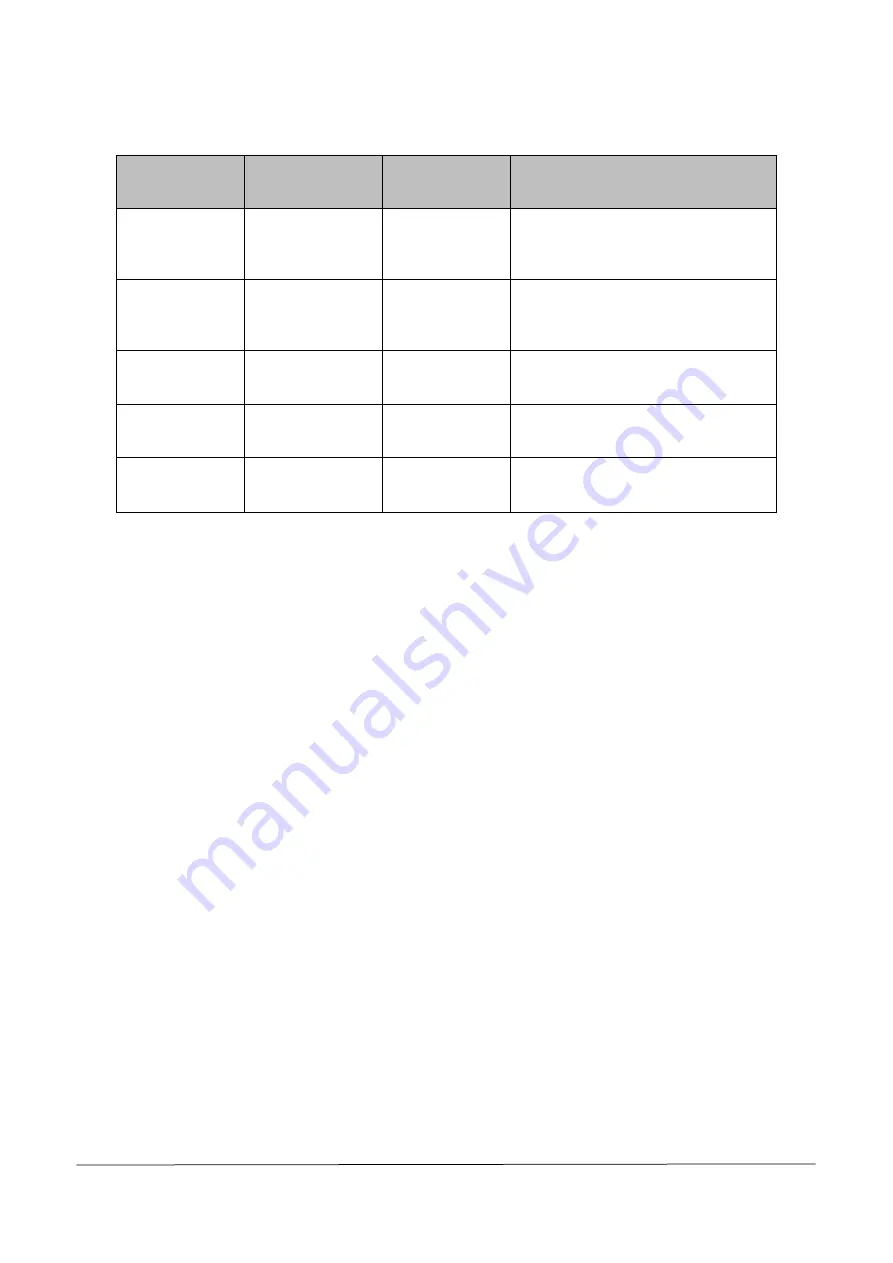

Appearance

Keep clean and

neat.

Once/per day

Wipe it with alcohol immediately and

keep it clean when splashing resin on

the guide rail or on the cover.

Alcohol in

cleaning box

Keep clean.

Once/every two

days (during

operation)

The wax pattern cannot be soaked in

alcohol for too long, which will cause

the wax pattern to soften.

LCD panel

Confirm whether it

works normally.

Once/per week

—

Build platform

leveling

Confirm the

leveling state.

Once/every 30

days

—

Guide rail and

screw rod

Keep lubricant.

Once/every 3

months

Maintain lubrication with lubricating

oil.