LF(R) Series Operation Manual

3 Various Measuring Methods

- 53 -

3-8-4 Cancellation of last collected data

You can only cancel the data collected last.

1

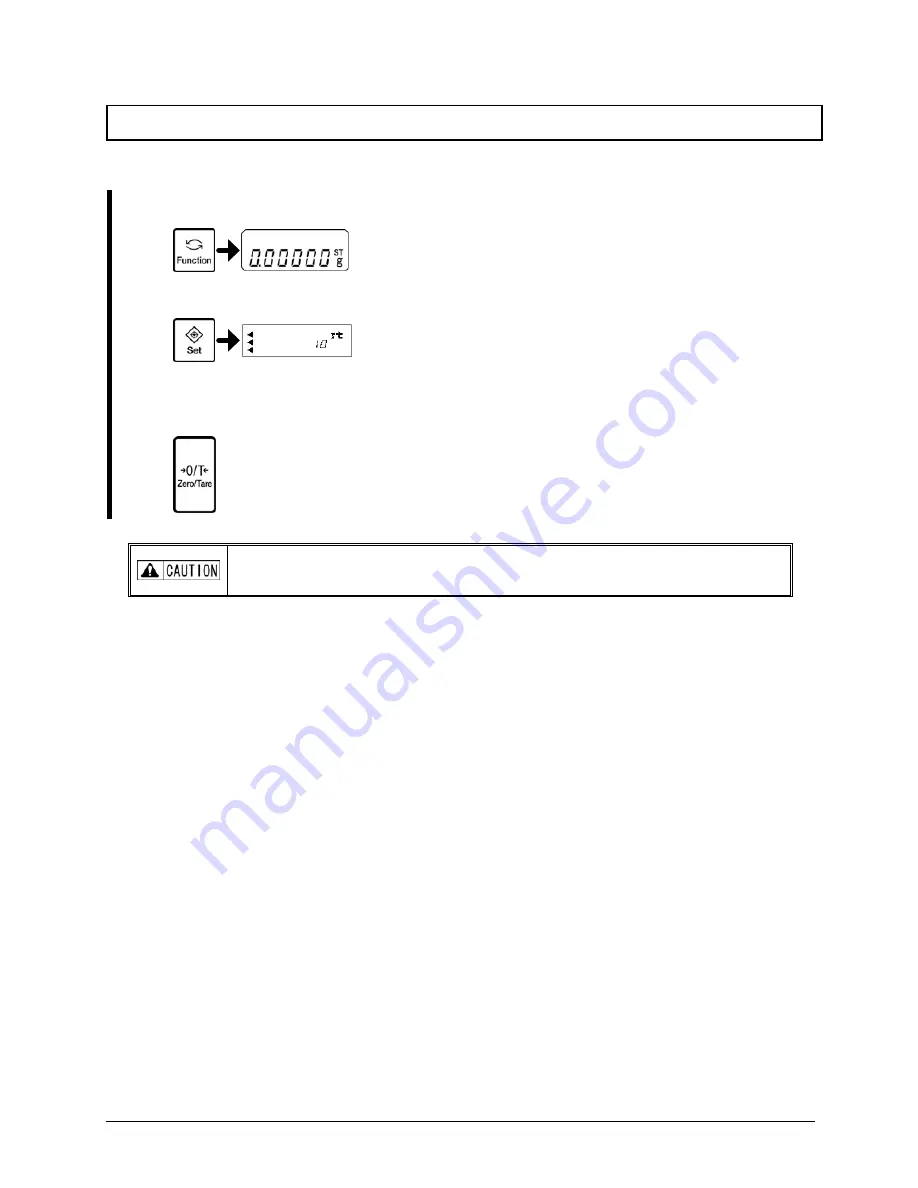

Set to the statistical operation display.

Press the [Function] key when the balance is displaying

the weight.

Do this before collecting the next data item.

2

Set the calculation item to “Number of data items.”

Press the [Set] key several times until the calculation item

is set to “Number of data items.”

When the calculation item is “Number of data

items,” three “(Insert the image of the black

triangle on the left-hand side)” symbols light up.

3

Cancel the last collected data.

Press the [Zero/Tare] key.

The last collected data is cancelled and

“CANCEL” is output.

You cannot cancel the second to last data. If you press the [Zero/Tare] key after

cancelling data once, “8-Err” is displayed.

Summary of Contents for LF124R

Page 130: ...7 Troubleshooting LF R Series Operation Manual 120 Memo ...

Page 131: ...LF R Series Operation Manual Appendixes 121 Appendixes Appendix 1 Function Setting List ...

Page 132: ...Appendixes LF R Series Operation Manual 122 ...

Page 133: ...LF R Series Operation Manual Appendixes 123 ...

Page 134: ...Appendixes LF R Series Operation Manual 124 ...

Page 135: ...LF R Series Operation Manual Appendixes 125 ...

Page 136: ...Appendixes LF R Series Operation Manual 126 ...

Page 137: ...LF R Series Operation Manual Appendixes 127 ...

Page 138: ...Appendixes LF R Series Operation Manual 128 ...

Page 139: ...LF R Series Operation Manual Appendixes 129 ...

Page 144: ...Appendixes LF R Series Operation Manual 134 α check Display test α check Key test ...

Page 145: ...LF R Series Operation Manual Appendixes 135 α check Motor test Span adjustment history ...

Page 149: ...LF R Series Operation Manual Appendixes 139 Appendix 4 4 Unit Conversion Table ...

Page 150: ...Appendixes LF R Series Operation Manual 140 Appendix 4 5 Outline Drawings ...

Page 153: ......

Page 154: ......