1

Check and ensure that no raised grain or splinters are

evident on timber components. Sand down any

raised grain or splinters using fine grade sandpaper.

2

Check that all screw, nail and pin heads are properly

tapped home and are not proud of the timber surface.

3

Check and ensure that no screws, nails or pins

protrude through any panel.

4

Check and ensure that all parts are properly secured

against reasonable force.

5

Do not apply decorative wood finish/treatments to wet

or damp timber. Please observe the instructions of the

wood finish/treatment manufacturer.

6

Adults need to check the playhouse regularly and

maintain the playhouse in good condition to provide a

safe play environment. Do not use if damaged. If

damaged the playhouse should be properly and

safely repaired before further use by children.

Assembly Completion Checklist

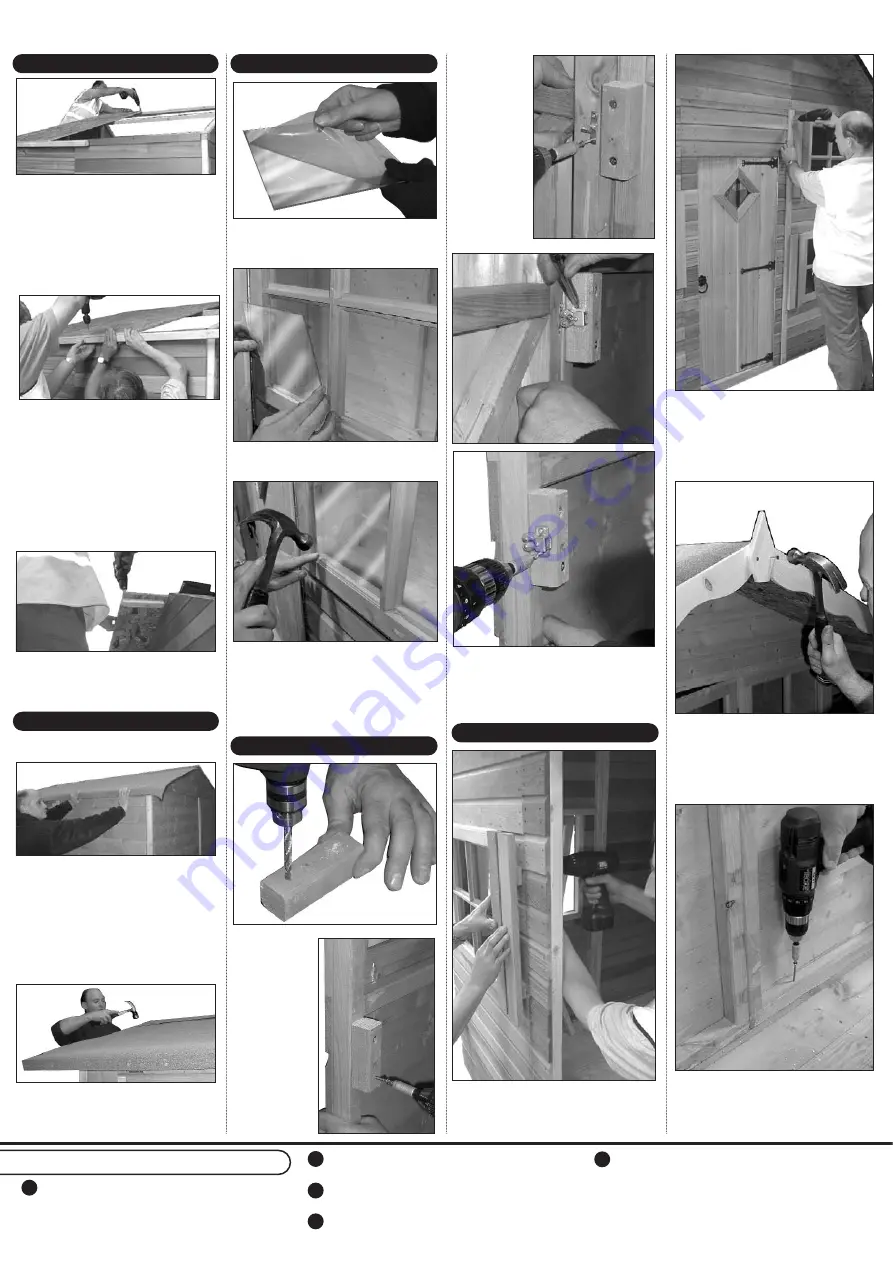

L

-

Glazing

M - Door Catch Assembly

1 Remove protective film from both sides of

each glazing pane of window glazing

material (B3).

2 Place glazing material (B3) into the

aperture of each window.

3 Hold into position with four pieces of

beading (B4). The beading may need to

be swapped around to get the best fit.

When satisfied secure into position using

2x 15mm panel pins per piece of

beading.

1 Drill x 2

holes into

the wood

block and

secure to

inside of

door

opening

flush with

the aperture

using 2x

60mm

screws.

2 Secure door

catch to inside

of door

approximately

centrally

alongside the

wood block

and secure

using 2x

25mm screws.

3 Close the door and attach the door

catch together and mark the required

position of the door catch housing.

Secure using 2x 25mm screws.

1

Fit shutters (B1).

One person to hold

in place and another to secure from the

inside using 4x 25 mm screws, 2 into

each block.

N

-

Finishing Touches

4 Drill and screw all side panels to the

floor on the inside of the building using

1x 60 mm screw per panel, into a floor

joist if possible.

2 Fit coverstrips (G) over each panel join

and in each corner, using 3x 40 mm

nails per piece. There are two small

coverstrips to cover over the gable

joins. Secure using 2x 40 mm nails per

piece.

3 Fit facia and diamond to front and back

roof edging. The profiled facia (J1)

goes at the front of the building. Secure

using 3x 40 mm nails for each length of

facia and 2x 40 mm nails for each

diamond (K).

2 Attach a further roof piece (H) and a

further piece of edging framework (H1).

Attach using 3x 25mm screws in each

bearer and 2x 25mm screws into each

roof edging piece.

3 Fit the final roof piece as previous, using

2x 25mm screws into each roof bearer

and roof edging, and 3x 25mm screws

into the front wall. This roof piece will

leave an overhang. Repeat on the other

side.

4 Fit 2 small roof blocks (H3) to centre of

overhang and 1 block half way along

each half roof. Secure in position using

2x 25mm screws per piece.

2 Measure out and cut at 2000mm x 3

strips. Lay one piece of felt along the

longest lowest edge of the roof. An

overhang of approx 40mm should be

allowed on each of the 3 sides. Secure

using 13 mm felt nails at approximately

100 mm intervals, but do not nail down

along the centre of the building.

3 Repeat on the other side.

4 Place the final strip over the ridge

overlapping the other 2 pieces already

laid. Secure using 13 mm felt nails as

previously.

J

-

Fit Roof

1 Attach a piece of framework (H1) to one

edge of one large roof piece (H) using 4x

25mm screws. Place this roof panel in

position at the rear of the building. Ensure

that the roof is flush with the back wall

and point of gable. Screw into place using

3 x 25mm screws into the back wall and

2 x 25mm screws in each roof bearer

(H3). Repeat for other side.

K

-

Felt Roof

1 Break open roll of felt (I) and lay out on

an even surface.