16

TROUBLESHOOTING – FINDING AN AIR LEAK

If there are operational problems with the console bottoming out or not holding air, the procedure below can

help to narrow down the problem.

STEP 1:

Fill the system to max pressure using the fill toggle switch on the AUTOTUNE system. Allow the shocks to fully

extend by allowing the compressor to reach maximum pressure (around 200psi on the tank gauge) and record

the tank pressure.

STEP 2:

If the red ‘WAIT’ light is illuminated the compressor is running to fill up the air tank. This can take up to 5 minutes.

Once the green ‘READY TO FILL’ light is illuminated the air tank is full.

STEP 3:

Allow the console to sit for 3-4hrs or overnight if possible. Do not allow anyone to enter or add gear to the ICE

during this time.

STEP 4:

Measure all the shocks on the ICE and record the extended length as well as the tank pressure.

Tank pressure has dropped but

shocks are still measuring the

same extended length.

Tank is still at max pressure but

extended length of one or more

shocks has dropped.

• Potential air leak between

compressor and “FILL” solenoid

• Potential leak of shock or fitting

between “FILL” Solenoid and

“SET” solenoid.

• Check all fittings with soapy

water, replace or tighten any

loose fittings.

• Check the shock body fittings

with soapy water, replace or

tighten any loose fittings. If the

shock is leaking through its main

seal it will need to be removed

and repaired or replaced.

CONDITION

CAUSE

REMEDY

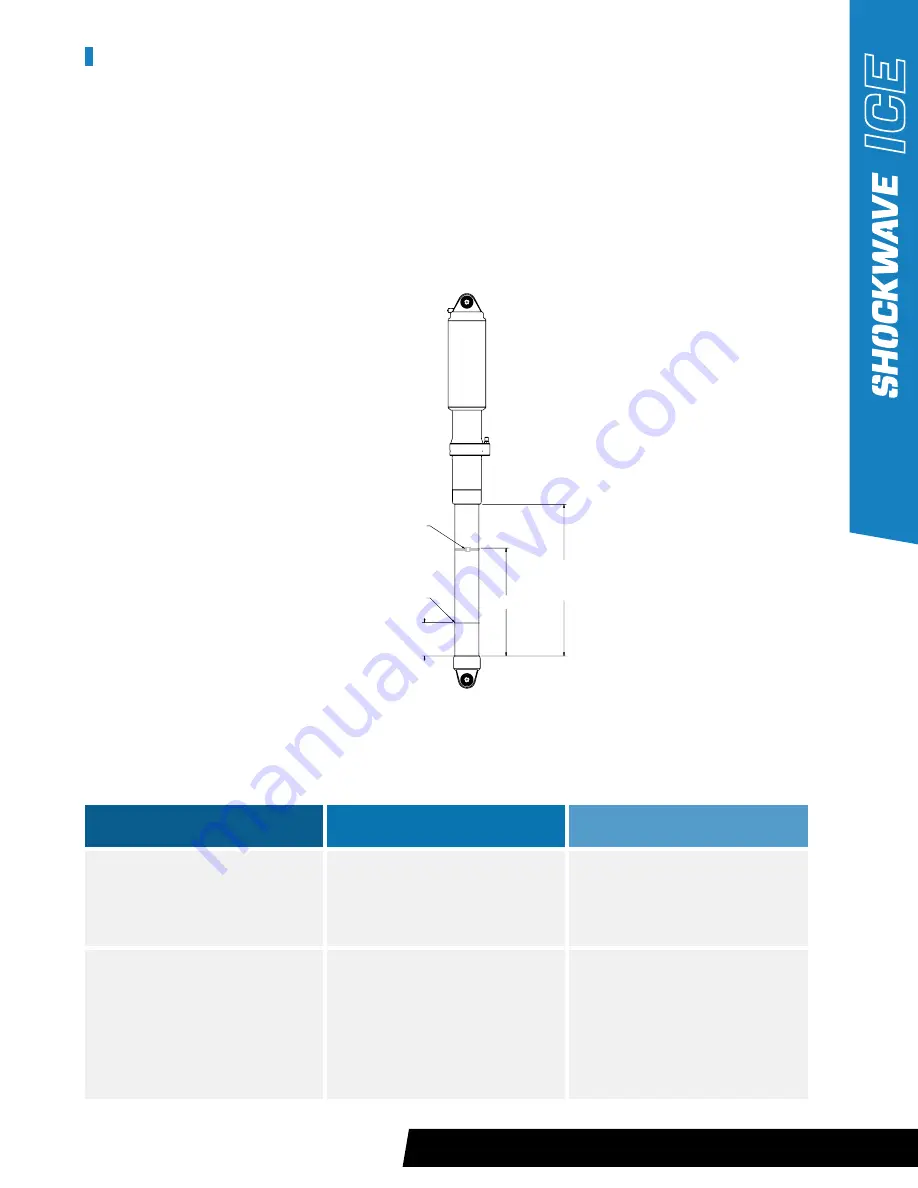

ZIP TIE

SAVE TRAVEL ZONE MARKER

[73mm]

2 7/8”

DIM #1

EXTENDED LENGTH

[354mm]

13-15/16”

TROUBLESHOOTING – FINDING AN AIR LEAK