ver.210629E

SHOWA DENKO K.K. (https://www.shodex.com/)

3

7. Column Usage Procedure

7.1 HPLC System Preparation

Wash entire LC system prior to the column installation, including all flow-lines and sample loop by switching the

valve, and then replace the washing solution with the eluent to be used. If desired new eluent has low

miscibility/solubility to the eluent of previous analysis, first use the eluent that is miscible/soluble to both eluents,

and then replace it with the desired eluent.

e.g. When replacing chloroform to acidic aqueous solution, first run methanol and water in that order, and then

introduce acidic aqueous solution.

Attention!

· If the eluent left in the system is not compatible with the column to be used, it may damage

the column.

· A drastic change in the eluent compositions may remove substances adsorbed on the

system and they may enter and deteriorate the column.

7.2 Column Installation

(1) Connect the column to LC system by following the “flow direction arrow” (

➡

) indicated on the column name

tag.

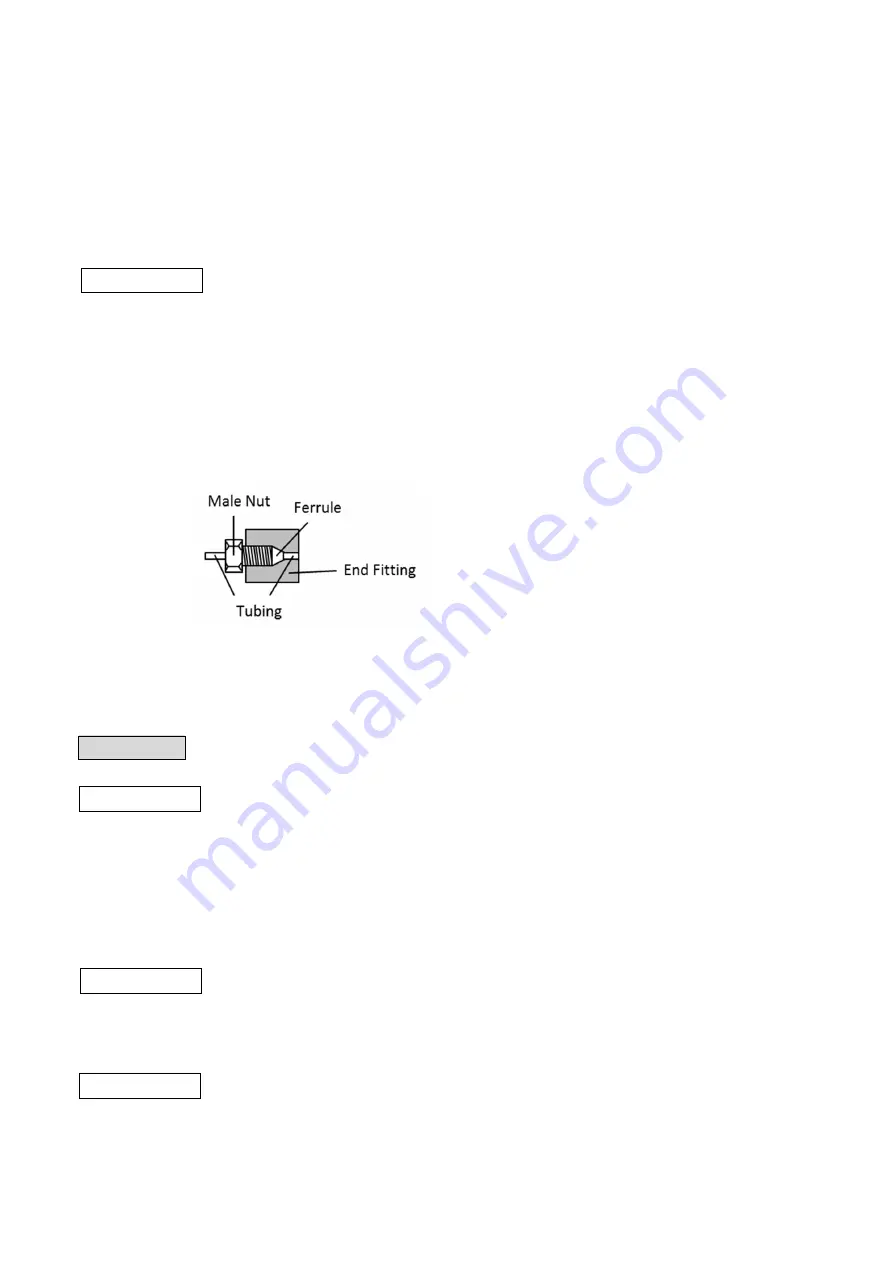

(2) Make sure to insert the tubing all the way to the end fitting and secure it with the male nut. It is important that

there is no extra space between the tubing and the column side of the end fitting. Presence of an extra space

will let the sample to spread out and may result in wide peaks.

(3)

Set the initial flow rate at 0.2 - 0.3 mL/min and start the system. If using the column at an elevated temperature,

keep a low flow rate until the temperature of the column reaches to the set temperature, and then gradually

increase the flow rate to the desired.

(4) At the end of analysis, reduce the flow rate to 0.2 - 0.3 mL/min and turn the column oven off. Make sure that

the column oven temperature is at room temperature before turning off the pump.

Caution!

· Verify that there is no solvent leak. It may cause electronic leakage, rust, and/or chemical

injury.

Attention!

·

Make sure not to let air bubbles enter the column while installing the column. The air

bubbles may damage the column.

· When restarting the system after column installation or after holding the eluent flow, start

the system at 0.2 - 0.3 mL/min. A rapid increase in pressure can damage the column.

· If the column was used at an elevated temperature, let the column temperature return to

room temperature before stopping the pump. If the pump was stopped while the eluent

inside the column was still hot, as the eluent temperature decreases, its volume also

decreases. This may result in creating an empty space in the column and deteriorates the

column.

Note

· It is recommended to set the pump limiter to avoid exceeding the maximum pressure.

7.3 Solvent Exchange

When replacing the solvent, set the column temperature at 50 °C and start the system at 0.2 - 0.3 mL/min.

Recommended solvent volume to introduce at each step is 3 to 5 times of the column volume.

Attention!

·

Frequent eluent replacement may damage the column, and thus not recommended.