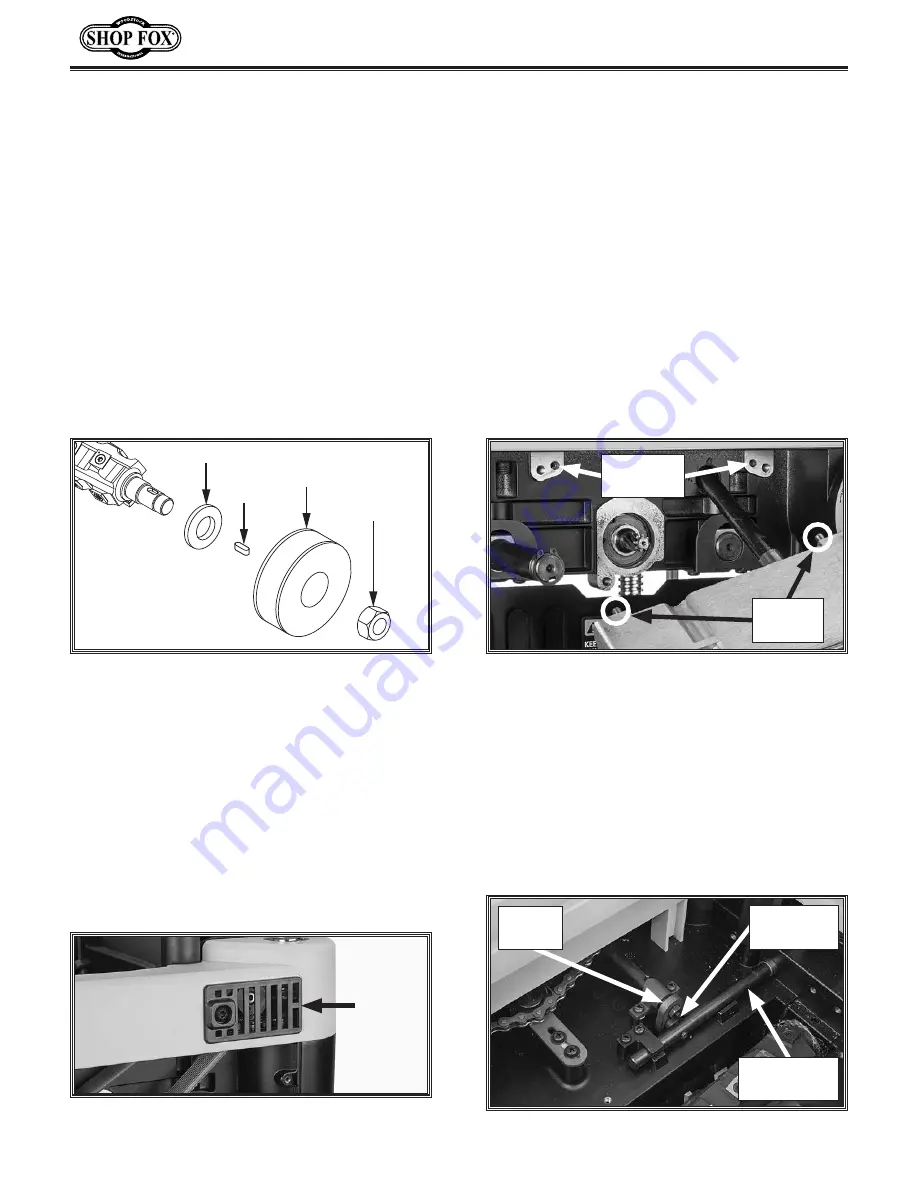

Spacer

Key

24mm

Nut

Cutterhead

Pulley

Figure 18. Cutterhead pulley assembly.

Figure 19. Drive belt cover location.

Figure 20. Gearbox locating pin alignment.

Alignment

Holes

Locating

Pins

Figure 21. Speed selector rod and "U" bracket.

"U"

Bracket

Speed

Selector Rod

Positioning

Pin

-6-

D4934 13" Helical Cutterhead Instructions

8. Seat 6204-2NSE ball bearing into right

bearing bore using threaded cutterhead end

as an alignment guide.

9. Use 40mm deep well socket or wood

block to gently tap bearing into bore until

retaining ring groove is visible and bearing

is flush with internal carriage wall.

10. Re-install retaining ring into bearing bore.

11. Insert wood board between cutterhead and

cutterhead carriage. Verify cutterhead no

longer rotates.

12. Install spacer, key, and cutterhead pulley

onto cutterhead end (see

Figure 18).

13. Re-install 24mm hex nut onto cutterhead

pulley.

14. Remove hex bolt and install helical pinion

gear.

15. Remove wood board.

16. Remove drive belt cover located on right

side (see

Figure 19) and verify that drive

belt is centered on drive wheel.

17. Gently stretch drive belt over cutterhead

pulley while slowly rotating pulley

clockwise until belt is centered.

Note: Drive belt and pulley wheels have

grooves along their surface for alignment.

18. Verify drive belt is centered on cutterhead

and drive pulleys before re-installing drive

belt cover.

19. Turn speed selector switch clockwise to

speed "2".

20. Re-install gearbox by aligning both locating

pins on gearbox assembly with both

alignment holes on planer (see

Figure 20).

21. While installing gearbox, confirm that "U"

bracket attached to speed selector switch

engages with positioning pin on gearbox

speed selection rod (see

Figure 21).

Note: If gearbox

does not

fully seat during

Steps 20–21

, slowly rotate cutterhead

pulley back-and-forth to re-align helical

pinion gear with gearbox.