-21-

Model M1117 (For Machines Mfd. Since 9/21)

O

PE

R

ATIO

NS

Adjusting.Front.Work.Stop

The front work stop keeps the shearing blades from

pushing the workpiece forward during cutting operations.

Use the following steps to adjust the front work stop

to the front workpiece edge once the workpiece has

been inserted under the blade guard and is ready to be

sheared.

To.adjust.front.work.stop,.do.these.steps:

1..

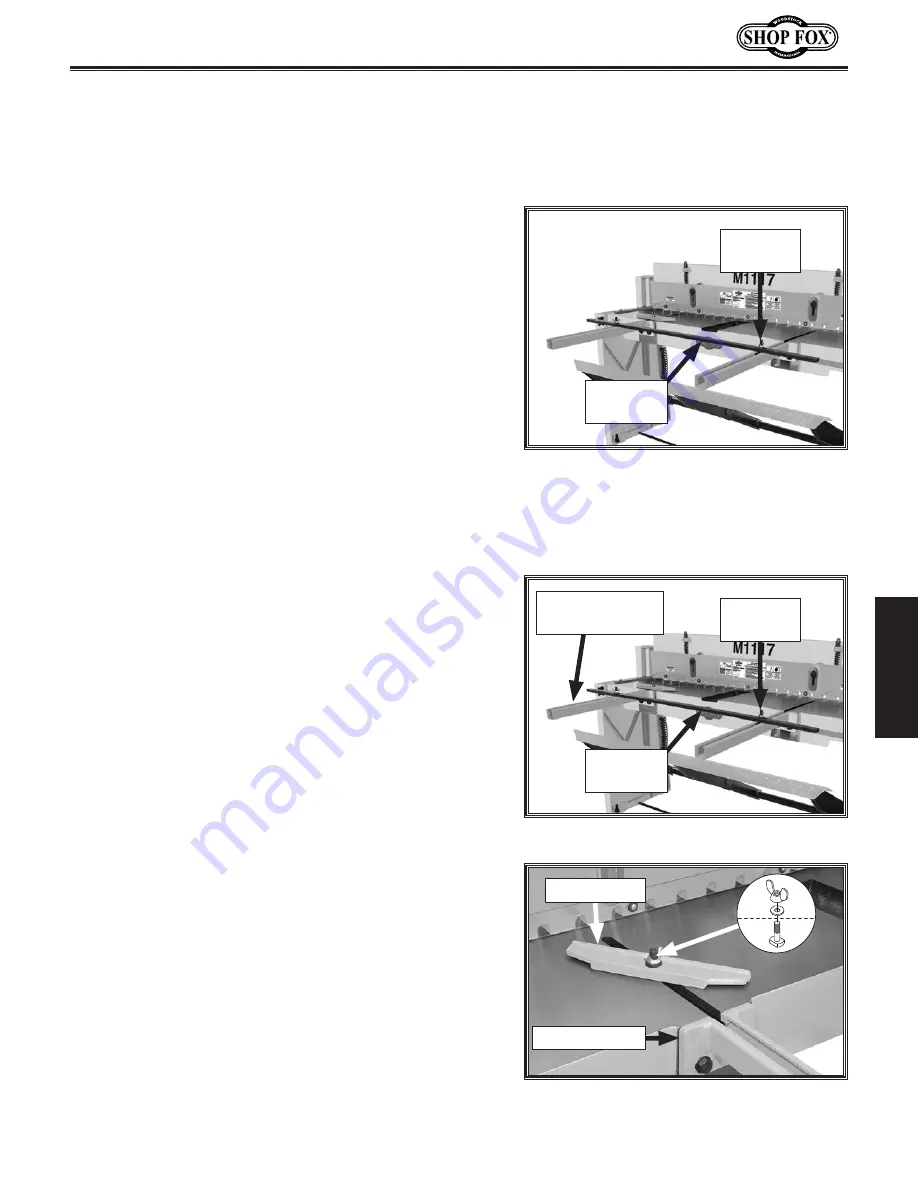

Loosen (2) front work stop wing nuts (see

Figure

19

).

2..

Adjust front work stop against front workpiece edge

and tighten wing nuts to secure.

Figure.19.

Location of front work stop

wing nuts.

Front

Work Stop

Wing Nut

(1 of 2)

Using.Bevel.Gauge

The bevel gauge can be installed in place of the front

work stop to support workpieces that have an angled

front edge.

To.use.bevel.gauge,.do.these.steps:

1..

Loosen (2) front work stop wing nuts (see

Figure

20

).

2..

Slide front work stop out of front extension arms to

remove (see

Figure

20

).

3..

Position workpiece on table and under blade guard

for shearing operation.

Figure.20.

Front work stop components.

Front

Work Stop

Wing Nut

(1 of 2)

Front Extension

Arm (1 of 2)

4..

Install (1) M12-1.75 x 45 T-bolt in T-slot and secure

bevel gauge to extension arm or table against

workpiece front edge with (1) 12mm flat washer and

M12-1.75 wing nut (see

Figure

21

).

Note:

Figure 21

shows bevel gauge installed in left

T-slot, but it can be installed in either side. Install

the bevel gauge in the best position to secure your

workpiece for the operation.

Figure.21.

Bevel gauge installed to

support angled front workpiece edge.

Bevel Gauge

Extension Arm

4..

Tighten micro-adjustment lock knobs to secure rear

work stop position.

Summary of Contents for M1117

Page 40: ......