-32-

Model M1117 (For Machines Mfd. Since 9/21)

SE

RV

IC

E

Adjusting.

Hold-Down/Blade.Guard

When the upper blade is lowered, the blade guard is also

engaged to contact and secure the workpiece during the

cutting operation. The blade guard must be parallel with

the table to correctly secure workpieces.

Tools.Needed.

Qty

Feeler Gauge Set ...............................................1

Wrench or Socket 19mm .......................................1

Adjusting.Blade.Guard.Clearance

For an extra thin or thick workpiece, the guard can be

adjusted for the correct amount of clearance to secure it.

To.adjust.blade.guard.clearance,.do.these.steps:

1..

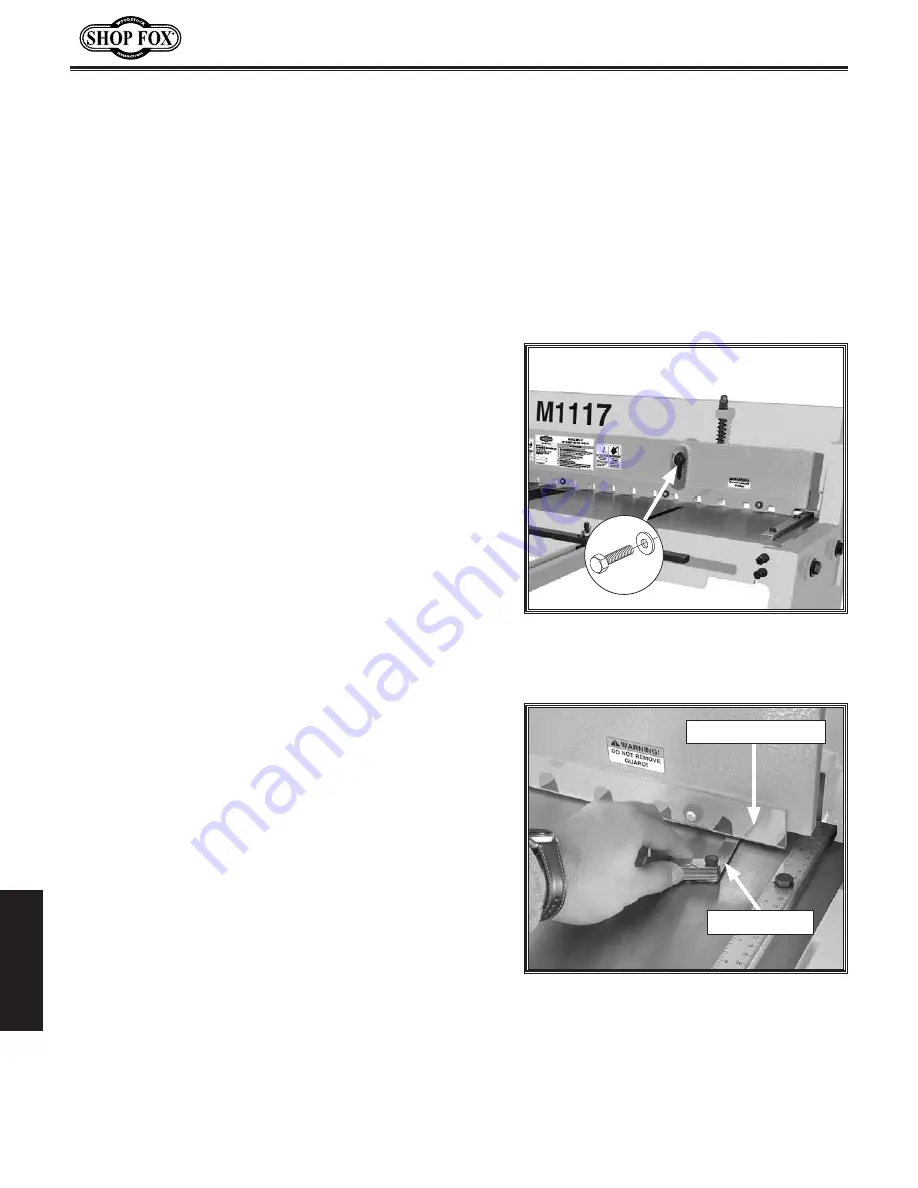

Loosen (2) blade guard hex bolts (see

Figure

33

).

2..

Adjust blade guard up or down to accommodate

workpiece thickness.

3..

Tighten (2) blade guard hex bolts to secure.

4..

Place edge of workpiece under blade guard, then use

foot pedal to confirm workpiece is secured by guard.

5..

Refer to following section to verify guard parallelism.

Figure.33.

Location of blade guard hex

bolts.

x 2

Adjusting.Blade.Guard.Parallel.With.Table

1..

Use foot pedal to lower and hold blade guard in

lowest position.

2..

Insert largest feeler gauge that will fit between

hold-down finger and table on right end of blade

guard (see

Figure

34

).

3..

Repeat

Step 2 on left end of blade guard.

— If both hold-down fingers are same distance from

table, no adjustment is required.

— If both hold-down fingers are not same distance

from table, proceed to

Step 4.

4..

Loosen blade guard hex bolt on side of blade guard

that needs adjustment.

5..

Adjust blade guard until entire length is same

distance from table, then tighten hex bolt.

Figure.34.

Using feeler gauge to check

blade guard clearance.

Hold-Down Finger

Feeler Gauge

Summary of Contents for M1117

Page 40: ......