-16-

Model M1117 (For Machines Mfd. Since 9/21)

SE

TU

P

Assembly

Figure.11.

Extension arm correctly

installed.

Before beginning the assembly process, refer to

Items.

Needed.for.Setup

and gather everything you need.

Ensure all parts have been properly cleaned of any

heavy-duty rust-preventative applied at the factory (if

applicable). Be sure to complete all steps in the assembly

procedure prior to performing the

Test.Run.

or connecting

the machine to power.

To.assemble.machine,.do.these.steps:

1..

Use level to check shear table.

— If table is level, no adjustment is required. Proceed

to

Step 2.

— If table is not level, use shims between floor and

base to level machine before proceeding. Leveling

shear helps blades and other components remain

straight and flat during life of machine so machine

can continue to cut straight and square.

2..

Cut cable ties securing foot pedal to table.

3..

Have another person press and hold foot pedal about

halfway through full range of movement.

4..

Insert (2) 12 x 45mm clevis pins in holes in foot

pedal frame and secure with (2) M3 x 50 cotter pins,

as shown in

Figure

9

.

Figure.9.

Location of hole in foot pedal

frame (1 of 2 shown).

x 2

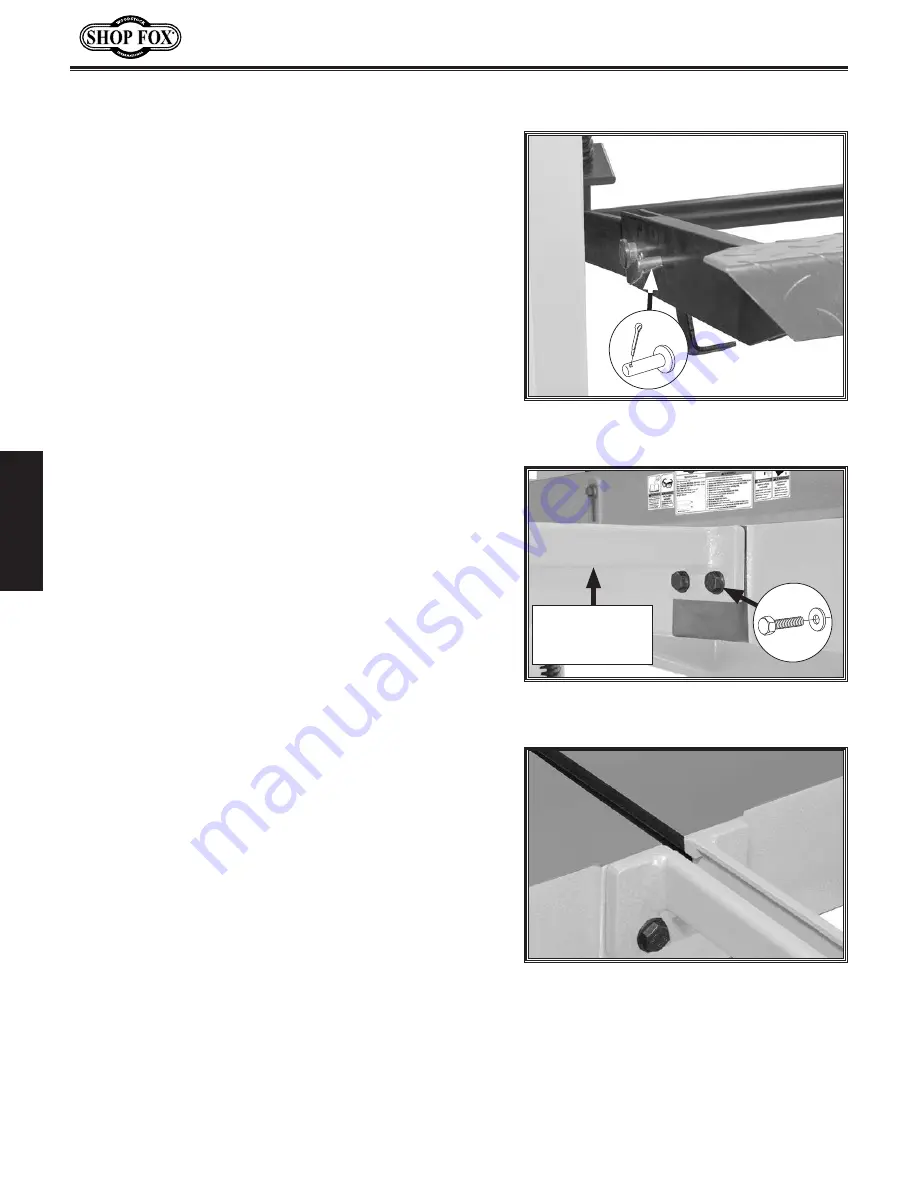

5..

Attach (2) front extension arms to shear table with

(4) M12-1.75 x 30 hex bolts and 12mm flat washers

(see

Figure

10

).

Note:

Arm T-slots must line up with table T-slots,

and surfaces must be flush (see

Figure 11

).

Figure.10.

Front extension arms attached

to shear table.

Front

Extension Arm

(1 of 2)

x 4

Summary of Contents for M1117

Page 40: ......