Model D3736 Palm Finishing Sander

-11-

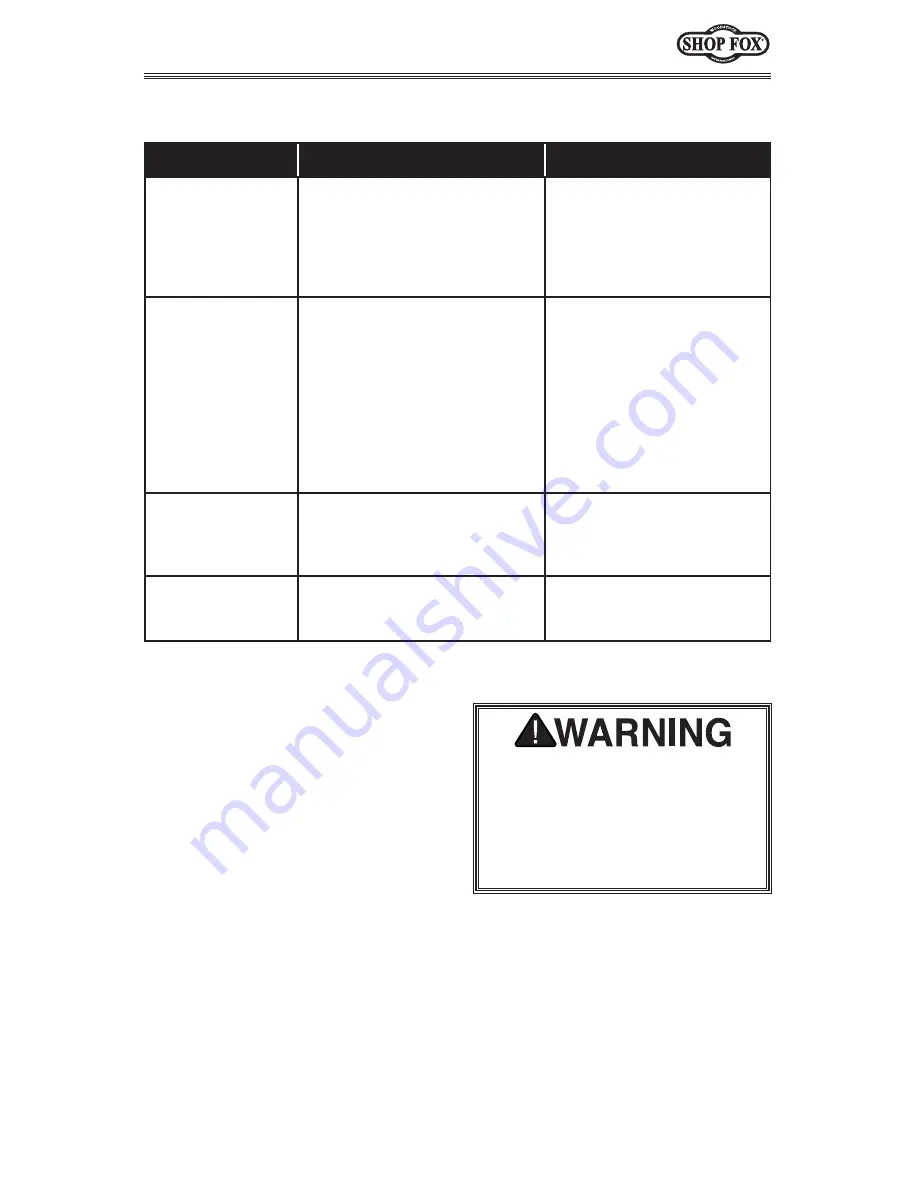

Troubleshooting

Symptom

Possible Cause

Possible Solution

Reduced amount of

material removed

by sander, quality

of finish decreases,

sander slides easily

across workpiece.

1. Sandpaper clogged with paint

or glue.

2. Sandpaper grit dull.

1. Replace sandpaper.

2. Replace sandpaper

Sander generates

excessive dust

particles.

1. Dust bag full.

2. Holes on sandpaper not

aligned with holes in sander

base.

3. Sandpaper lacks holes.

4. Holes in sander base clogged.

1. Empty dust bag.

2. Use abrasive paper with

pre-punched holes that

match holes on base.

3. Cut or punch holes in

sandpaper to match holes

on sander base.

4. Clean dust collection

holes in base with dry

compressed air.

Sander runs slowly,

becomes hot, or

sanding efficiency

decreased.

1. Excessive pressure placed on

sander.

2. Brushes are at fault.

3. Motor is at fault.

1. Apply less pressure on

sander.

2. Replace brushes.

3. Replace motor.

Sander fails to

start.

1. Sander plug prongs loose in

wall outlet.

2. Switch clogged with dust.

1. Plug sander back into

outlet so they fit snugly.

2. Clean switch.

Disassembly and improper

reassembly of this device can

result in electrical shock. Always

have this device serviced by

a qualified electrical repair

technician to avoid serious injury.

All quality tools will eventually wear from

normal use. Since this sander is encased

in an insulated plastic cover, leave

repair and service issues to a qualified

service technician. This includes brush

replacement, lubrication or any other

internal operation.

See the

Parts Breakdown

on

Page 9

for

replacement parts.

You can replace the rubber backing

pad that holds the abrasive sheet if it

becomes worn. Remove the four screws

that hold the backing plate to the

body of the sander and replace with

a new rubber backing piece, installing

the reverse of removal. Make sure

you tighten the rubber backing screws

sufficiently, so you don’t have problems

when you resume operations.

Repair