Model D3736 Palm Finishing Sander

-6-

OPERATIONS

Getting Started

To test the sander, do these steps:

1.

Plug the cord into a 110V outlet.

2.

Move the switch (located at the front

of the sander) to the “—” position to

turn the sander

ON

, and move the

switch to the “O” position to turn the

sander

OFF

.

The sander should run smoothly. Strange

or unusual noises should be investigated

and corrected before operating further.

If you cannot easily locate the source of

an unusual noise or vibration, contact

Technical Support for help.

If you have not read the safety

instructions in this manual, do not

operate the sander.

This palm sander is designed to use

1

⁄

4

sheets of hook and loop sandpaper

measuring 4

1

⁄

4

" x 4

1

⁄

2

". You may purchase

4

1

⁄

2

" x 5

1

⁄

2

" sandpaper and cut it to size,

or cut standard 9" x 11" sanding sheets

into 4 pieces each measuring 4

1

⁄

4

" x 4

1

⁄

2

",

or cut sheets out of a 4

1

⁄

2

" wide sanding

roll.

To attach the sandpaper, do these

steps:

1.

UNPLUG THE SANDER FROM POWER

SOURCE!

2.

Hold the sander upside down with its

top against a flat, stable surface.

3.

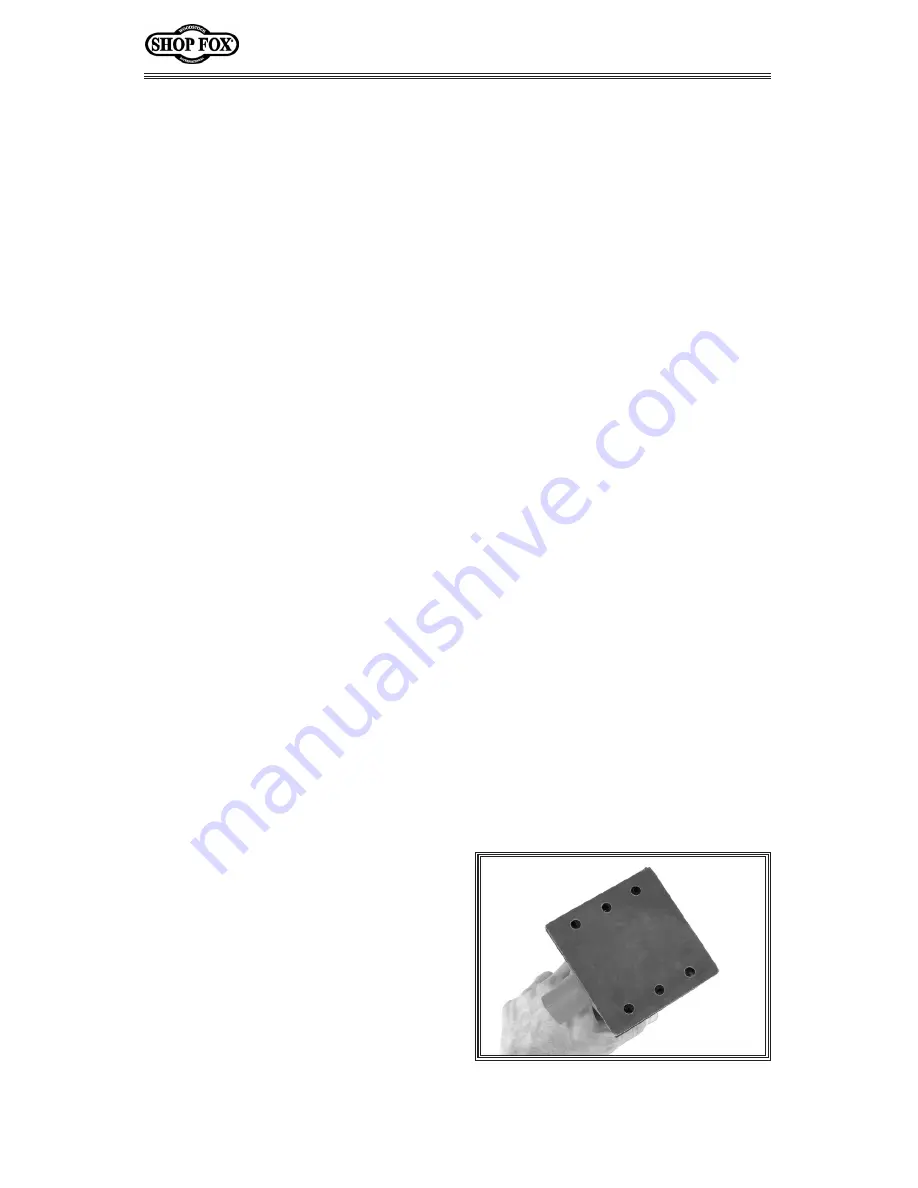

Place the sandpaper over the base

and align the holes in the paper with

holes in the base (

Figure 1

).

Attaching Abrasives

Selecting Abrasives

The best results from your D3736 Palm

Finishing Sander will be accomplished

using the proper grit of coated abrasive.

As a general rule, start with a coarse grit

size and move through finer grit sizes

until you achieve your desired finish.

Use the list below to define paper grit

sizes:

• Extra Coarse

........................ 12-20

• Very Coarse

......................... 24-36

• Coarse

............................... 40-50

• Medium

............................ 60-100

• Fine

............................... 120-180

• Very Fine

......................... 220-280

• Extra Fine

........................ 320-400

Any time you are unsure about which grit

to begin with, experiment on a hidden

area of your project. Ideally, you want to

achieve the balance of removing defects

without damaging your work.

Aluminum oxide and silicon carbide

abrasives are an excellent choice because

they last longer and are sharper than

natural abrasives.

Figure 1.

Sandpaper and base holes

aligned.