-40-

Model W1680 (For Machines Mfd. Since 06/22)

SE

RV

IC

E

4...

Pull cover outward just enough to disengage spring

cover lock slot from locking lug (see

Figure.45

).

5...

Rotate cover counterclockwise to increase spring

tension, or let cover slowly unwind in clockwise

direction to reduce spring tension.

6...

Engage next available spring-cover lock slot with

locking lug, and hold spring lock cover tightly against

side of headstock.

7...

Snug cover nut against spring cover just until nut

stops, and then back-off the nut approximately

1

⁄

3

turn, or just enough so there is no binding anywhere

along complete spindle travel.

8...

Hold cover nut and tighten jam nut against cover nut

(see

Figure.43

).

Figure.45.

Typical spring cover lock slot

and locking lug.

Locking Lug

Spring Cover

Lock Slot

Adjusting.Quill.Shaft.

Screw

While you may never have to adjust the quill shaft

screw, you should understand its function and know how

to adjust it should you ever need to remove the quill for

cleaning. This screw prevents the quill from rotating dur-

ing operations, and if adjusted incorrectly, the quill may

have lash or bind.

3...

Loosen jam nut shown in

Figure.46.

4...

Turn quill shaft screw clockwise or counterclockwise

to establish free, unbinding travel while moving quill

up and down through its entire range of travel.

5...

When quill shaft screw is screwed inward against

quill as far as screw can go without binding quill,

hold screw and tighten jam nut.

6...

Recheck for quill binding and looseness while moving

quill up and down through its entire range of travel

and readjust as required.

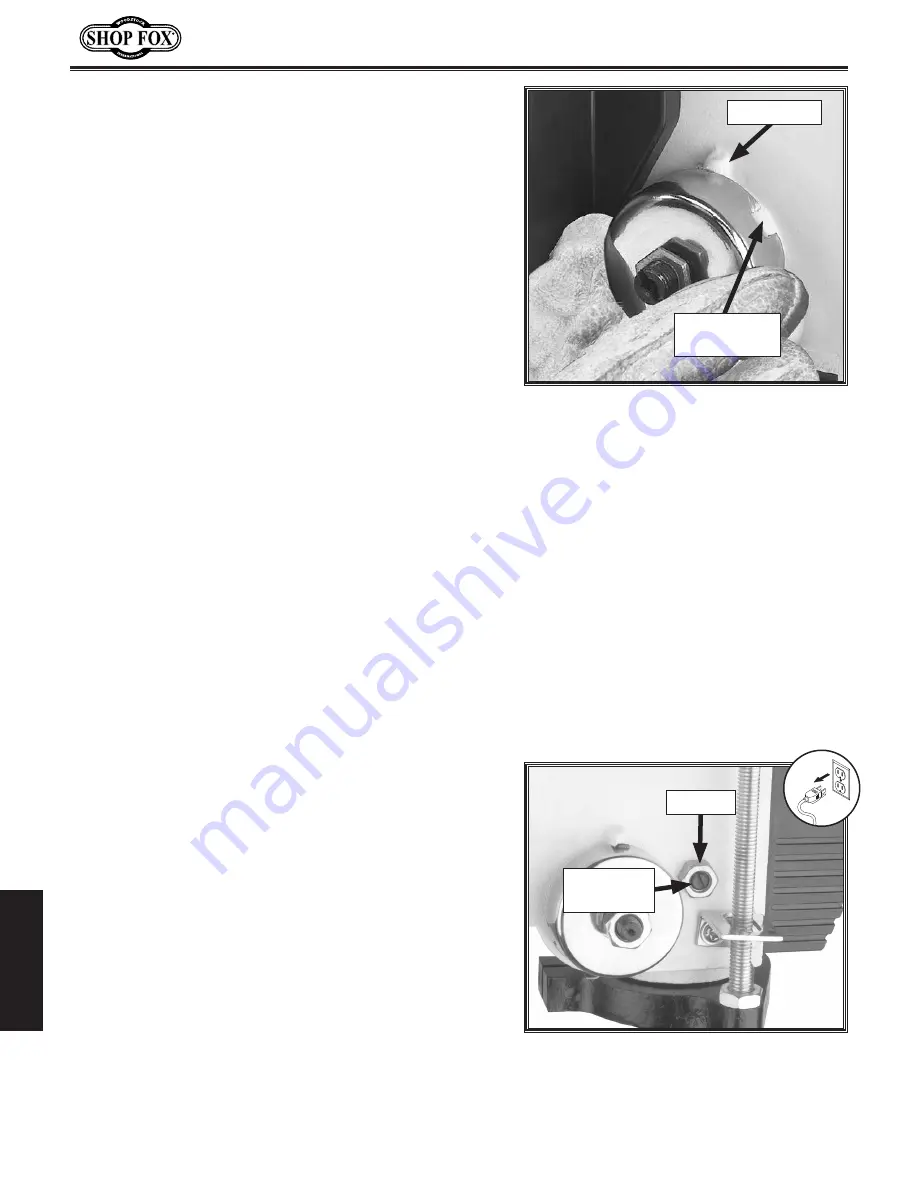

Figure.46..

Typical quill-shaft screw and

jam nut.

Jam Nut

Quill Shaft

Screw

Tools.Needed.

Qty

Open-End Wrench 16mm.......................................1

Hex Wrench 5mm ...............................................1

To.adjust.quill.shaft.screw,.do.these.steps:

1.

DISCONNECT MACHINE FROM POWER!

2.

Clean and lubricate quill as described in

Lubrication

on

Page 37. Quill should travel freely.