-41-

Model W1680 (For Machines Mfd. Since 06/22)

SE

RV

IC

E

Troubleshooting

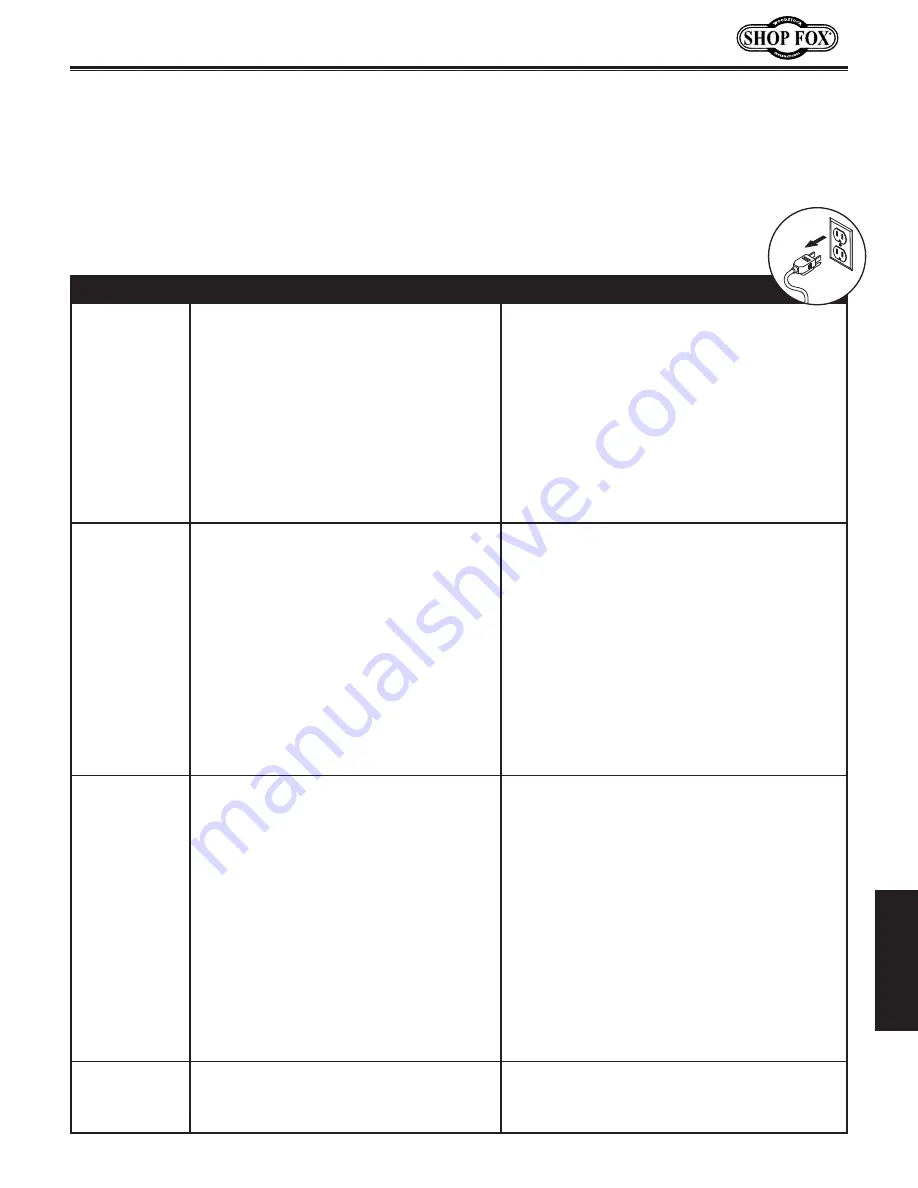

Motor.and.Electrical

PROBLEM

POSSIBLE.CAUSE

CORRECTIVE.ACTION

Machine does not

start, or power

supply breaker

trips immediately

after startup.

1. Switch disabling key removed.

2. Incorrect power supply voltage or circuit size.

3. Power supply circuit breaker tripped or fuse

blown.

4. Motor wires connected incorrectly.

5. Start capacitor at fault.

6. Centrifugal switch adjustment/contact points

at fault.

7. Wiring broken, disconnected, or corroded.

8. ON/OFF switch at fault.

9. Motor or motor bearings at fault.

1. Install switch disabling key.

2. Ensure correct power supply voltage and circuit size

(

Page 11).

3. Ensure circuit is free of shorts. Reset circuit break-

er or replace fuse.

4. Correct motor wiring connections (

Page 43).

5. Test/replace if at fault.

6. Adjust centrifugal switch/clean contact points.

Replace either if at fault.

7. Fix broken wires or disconnected/corroded connec-

tions (

Page 43).

8. Replace switch.

9. Replace motor.

Machine stalls or

is underpowered.

1. Workpiece material unsuitable for machine.

2. Feed rate/cutting speed too fast.

3. Belt(s) slipping/pulleys misaligned.

4. Motor wires connected incorrectly.

5. Pulley slipping on shaft.

6. Machine undersized for task.

7. Motor overheated.

8. Extension cord too long.

9. Centrifugal switch/contact points at fault.

10. Motor or motor bearings at fault.

1. Only cut wood with moisture below 20% and correct

type/size of metal.

2. Decrease feed rate/cutting speed (

Page 30).

3. Clean/tension/replace belt(s) (

Page 35); ensure

pulleys are aligned.

4. Correct motor wiring connections (

Page 43).

5. Tighten/replace loose pulley/shaft.

6. Use correct cutter/bit; reduce feed rate; reduce

spindle RPM (

Page 30); use cutting fluid if possible.

7. Clean motor, let cool, and reduce workload.

8. Move machine closer to power supply; use shorter

extension cord.

9. Adjust centrifugal switch/clean contact points.

Replace either if at fault.

10. Replace motor.

Machine has

vibration or noisy

operation.

1. Motor or component loose.

2. V-belt(s) worn, loose, pulleys misaligned or

belt slapping cover.

3. Pulley loose.

4. Motor mount loose/broken.

5. Spindle loose, improperly installed or

damaged.

6. Workpiece loose.

7. Motor fan rubbing on fan cover.

8. Chuck or cutter at fault.

9. Spindle bearings at fault.

10. Centrifugal switch needs adjustment/at fault.

11. Motor bearings at fault.

1. Replace damaged or missing bolts/nuts or tighten if

loose.

2. Inspect/replace belts with a new matched set

(

Page 35). Realign pulleys if necessary.

3. Secure pulley on shaft.

4. Tighten/replace.

5. Tighten loose spindle, re-install spindle ensur-

ing mating surfaces are clean, replace spindle if

damaged.

6. Use correct holding fixture and reclamp workpiece.

7. Fix/replace fan cover; replace loose/damaged fan.

8. Replace out-of-round chuck, dull, or bent cutter.

9. Test by rotating spindle; rotational grinding/loose

shaft requires bearing replacement.

10. Adjust/replace if at fault.

11. Test by rotating shaft; rotational grinding/loose

shaft requires bearing replacement.

Light bulb does

not illuminate.

1. Bulb burnt out.

2. Wiring broken, disconnected, or corroded.

3. Light ON/OFF switch at fault.

1. Replace light bulb.

2. Fix broken wires or disconnected/corroded

connections (

Page 43).

3. Replace switch.

The following troubleshooting tables cover common problems that may occur with this machine. If you

need replacement parts or additional troubleshooting help, contact our Technical Support.

Note:

Before contacting Tech Support, find the machine serial number and manufacture date, and if

available, your original purchase receipt. This information is required to properly assist you.