Model W1774 18-Gauge Brad Nailer

-15-

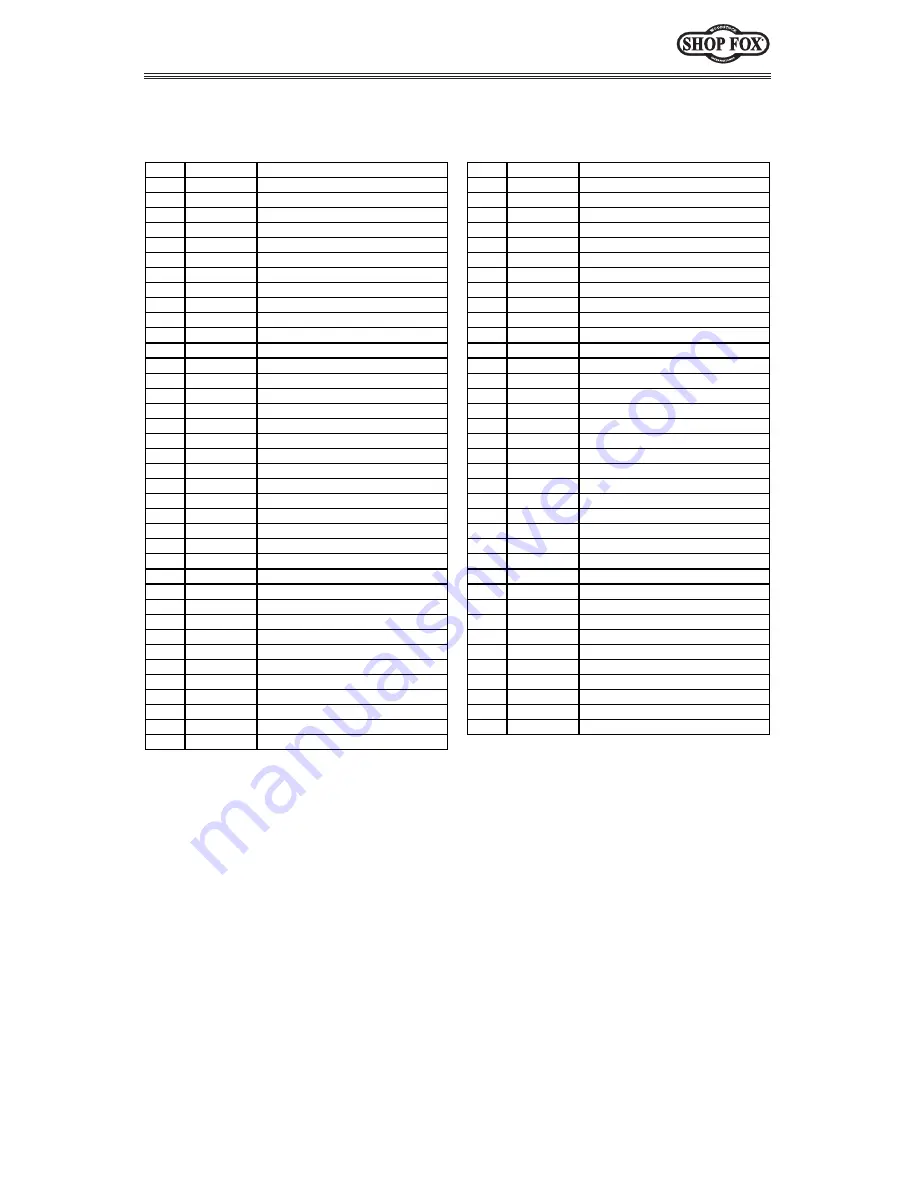

W1774 PARTS LIST

REF

PART #

DESCRIPTION

REF

PART #

DESCRIPTION

101

X1774101

STEPPED BOLT M4-.7 X 4, 6 X 7

143V2 X1774143V2 DRIVER GUIDE COVER V2.01.14

102

X1774102

EXHAUST CAP

144

X1774144

NAIL GUIDE LINER

103

X1774103

COMPRESSION SPRING 7.2 X 7

145

X1774145

MAGAZINE SEAT

104

X1774104

CAP SCREW M5-.8 X 20

146

X1774146

SET SCREW M4-.7 X 14

105

X1774105

LOCK WASHER 5MM

147

X1774147

MAGAZINE CAP

106

X1774106

CYLINDER CAP

148

X1774148

BRACKET

107

X1774107

O-RING 13.8 X 2.4 P14

149

X1774149

CAP SCREW M4-.7 X 14

108

X1774108

SEALING WASHER 2.5 X 31.2

150

X1774150

PUSHER

109

X1774109

COMPRESSION SPRING 8 X 7

151

X1774151

PUSHER SHAFT

110

X1774110

HEAD VALVE PISTON

152

X1774152

COMPRESSION SPRING 6.7 X 204

111

X1774111

O-RING 31.2 X 3.5 P13.5

153

X1774153

HEX NUT M4-.7

112

X1774112

O-RING 24.7 X 3.5 P25

154

X1774154

PIN 3 X 20

113

X1774113

CYLINDER CAP GASKET

155

X1774155

LATCH TORSION SPRING 6.2 X 9.4

114

X1774114

CYINDER SLEEVE

156

X1774156

LATCH

115

X1774115

O-RING 30 X 2.8

157

X1774157

CAP SCREW M4-.7 X 8

116

X1774116

O-RING 41.7 X 3.5 P42

158

X1774158

LATCH BRACKET

117

X1774117

CYLINDER

159

X1774159

CAP SCREW M4-.7 X 20

118

X1774118

O-RING 21 X 3

160

X1774160

RUBBER GRIP

119

X1774119

PISTON W/DRIVER

161

X1774161

O-RING 35.7 X 3.5 P36

120

X1774120

BUMPER

162

X1774162

CAP

121

X1774121

BODY

163

X1774163

AIR PLUG 1/4 NPT MALE

122

X1774122

RUBBER WASHER 4.5 X 8

164

X1774164

SAFETY GLASSES

123

X1774123

SEAL

165

X1774165

HEX WRENCH 4MM

124

X1774124

INNER VALVE SEAT

166

X1774166

HEX WRENCH 3MM

125

X1774125

TRIGGER VALVE GUIDE (INNER)

167

X1774167

CARRYING CASE

126

X1774126

O-RING 10.6 X 1.8

168

X1774168

PISTON REPAIR KIT

127

X1774127

TRIGGER VALVE GUIDE (OUTER)

169

X1774169

O-RING REPAIR KIT

128

X1774128

O-RING 11.2 X 2

170

X1774170

RUBBER WASHER

129

X1774129

COMPRESSION SPRING 9.1 X 17.5

171

X1774171

O-RING 36.3 X 3.55

130

X1774130

STEP PIN

172

X1774172

POSITION PIN

131

X1774131

TRIGGER

173

X1774173

COVER PLATE PIN

132

X1774132

E-CLIP 3MM

174

X1774174

CAP SCREW M4-.7 X 8

133

X1774133

SAFETY PLATE

175

X1774175

LOCK WASHER 4MM

134

X1774134

PIN

176

X1774176

SQUARE WASHER 4MM

135

X1774135

BRACKET

178

X1774178

AIR INLET PLUG CASE

136

X1774136

COMPRESSION SPRING 5.3 X 21

179

X1774179

BUMPER

137

X1774137

SAFETY NOSE

180

X1774180

QUICK RELASE HANDLE

138V2 X1774138V2 DRIVER GUIDE V2.01.14

181

X1774181

E-CLIP 2.5MM

139

X1774139

SPACER